Ever wondered why some hair dryers deliver powerful, efficient drying while others struggle despite similar wattage ratings? The secret lies in something most people overlook – the body shape and its sophisticated control over airflow dynamics.

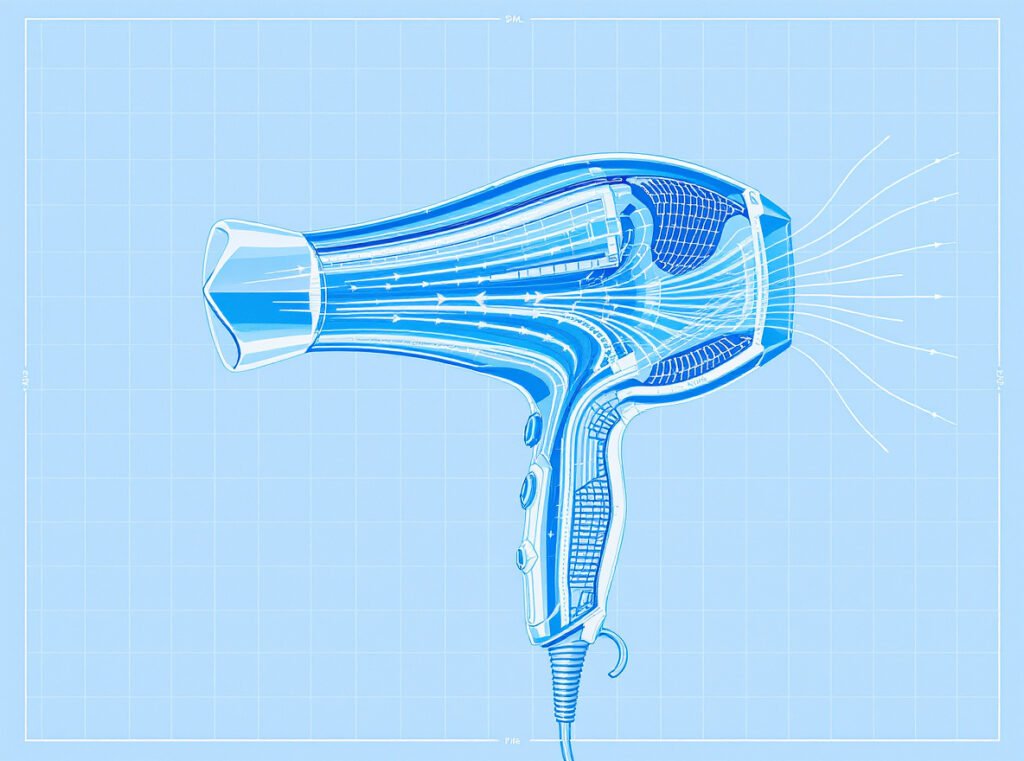

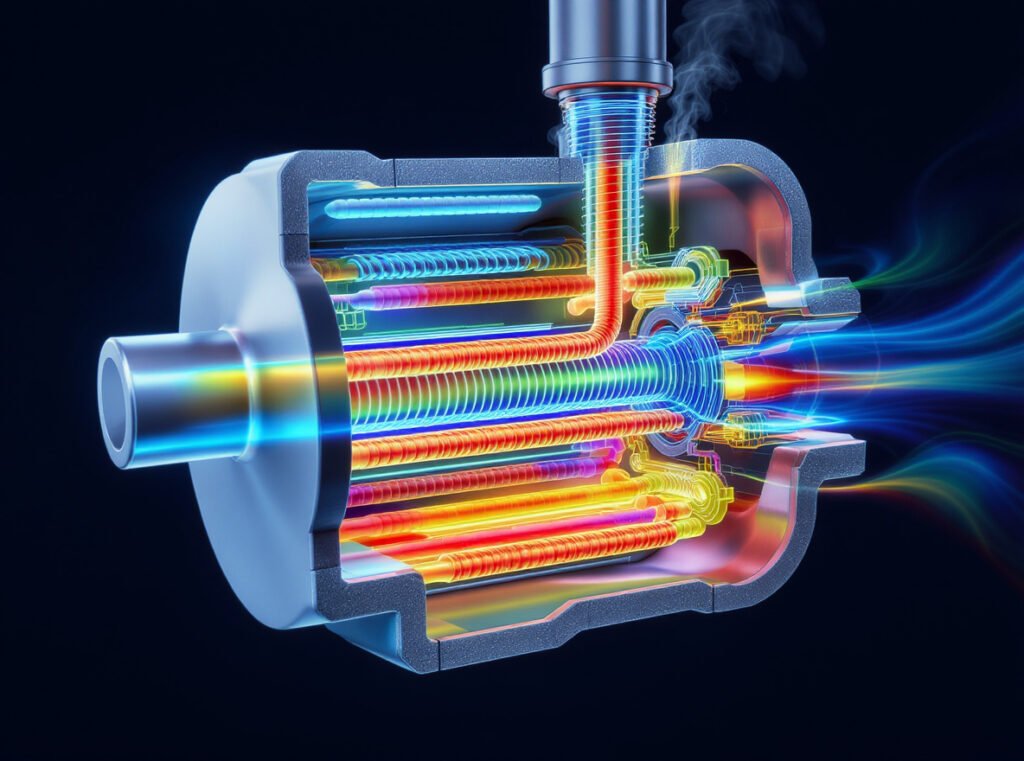

The shape of a hair dryer’s body fundamentally determines airflow efficiency by controlling air pressure transitions, velocity patterns, and heat distribution. Modern designs utilize Computational Fluid Dynamics (CFD) principles to optimize internal geometry, creating laminar flow paths that maximize drying effectiveness while minimizing energy waste and operational noise.

Understanding these aerodynamic engineering principles will help you select the most effective hair dryers for your business and deliver superior performance that satisfies demanding customers.

Table of Contents

ToggleWhy Does Hair Dryer Body Shape Control Airflow Performance?

Body shape serves as the critical engineering foundation that transforms raw motor power into controlled, effective airflow. Poor design creates turbulence that wastes energy and reduces performance, regardless of motor strength.

Hair dryer body shape controls airflow performance by managing the pressure transition from high-pressure motor output to controlled, directed air delivery. The internal geometry either maintains efficient laminar flow or creates disruptive turbulence, directly determining drying effectiveness, energy efficiency, and noise levels.

The physics behind optimal airflow involves sophisticated fluid dynamics principles. When air exits the motor at high pressure, the body shape guides its path through heating elements and toward the outlet. Well-designed internal geometries maintain smooth flow patterns that preserve air velocity and minimize energy losses.

Modern manufacturers increasingly employ Computational Fluid Dynamics (CFD) simulations to optimize these flow paths. This engineering approach explains why premium dryers often outperform higher-wattage competitors – superior aerodynamic design maximizes the effectiveness of available power.

Critical airflow factors influenced by body shape include:

- Pressure differential management: Smooth transitions prevent energy-wasting turbulence

- Laminar flow maintenance: Streamlined internal surfaces preserve air velocity

- Heat transfer optimization: Strategic chamber design maximizes heating efficiency

- Noise reduction: Proper airflow control minimizes turbulence-generated sound

Professional-grade dryers like the Conason P1C incorporate these advanced aerodynamic principles, delivering superior performance through optimized body geometry rather than simply increasing power consumption.

How Do Different Barrel Configurations Affect Air Velocity?

Barrel design represents the most visible and impactful aspect of airflow control, directly determining how air energy reaches hair surfaces. Understanding these configurations helps explain performance differences across dryer types.

Narrow concentrator barrels create focused, high-velocity airflow by compressing the air stream into smaller cross-sectional areas, increasing velocity proportionally according to fluid dynamics principles. Wide barrel designs prioritize air volume over velocity, distributing airflow across larger surface areas for comprehensive coverage of thick or long hair.

The relationship follows fundamental physics – as cross-sectional area decreases, velocity increases proportionally. However, optimal balance varies significantly by application:

High-Velocity Concentrator Design

Narrow barrels compress airflow into focused streams, typically increasing exit velocity by 40-60% compared to standard configurations. This concentrated energy proves particularly effective for precision styling and achieving smooth finishes because maximum air energy targets specific hair sections.

Volume-Optimized Wide Barrels

Wider configurations maintain lower velocities while dramatically increasing air volume delivery. This design excels for thick hair types requiring substantial air movement to penetrate multiple layers effectively.

Professional Variable Systems

Advanced dryers incorporate adjustable or interchangeable barrel systems, allowing users to optimize airflow characteristics for specific styling objectives.

| Barrel Configuration | Air Velocity Increase | Optimal Application | Coverage Area |

|---|---|---|---|

| Narrow Concentrator | +40-60% | Precision styling, smoothing | Small, focused |

| Standard Barrel | Baseline | General-purpose drying | Medium |

| Wide Distribution | -20-30% | Thick hair, volume drying | Large, dispersed |

The Conason P1C utilizes precision-engineered barrel geometry that balances velocity enhancement with sufficient volume delivery, providing professional-grade performance suitable for demanding commercial applications.

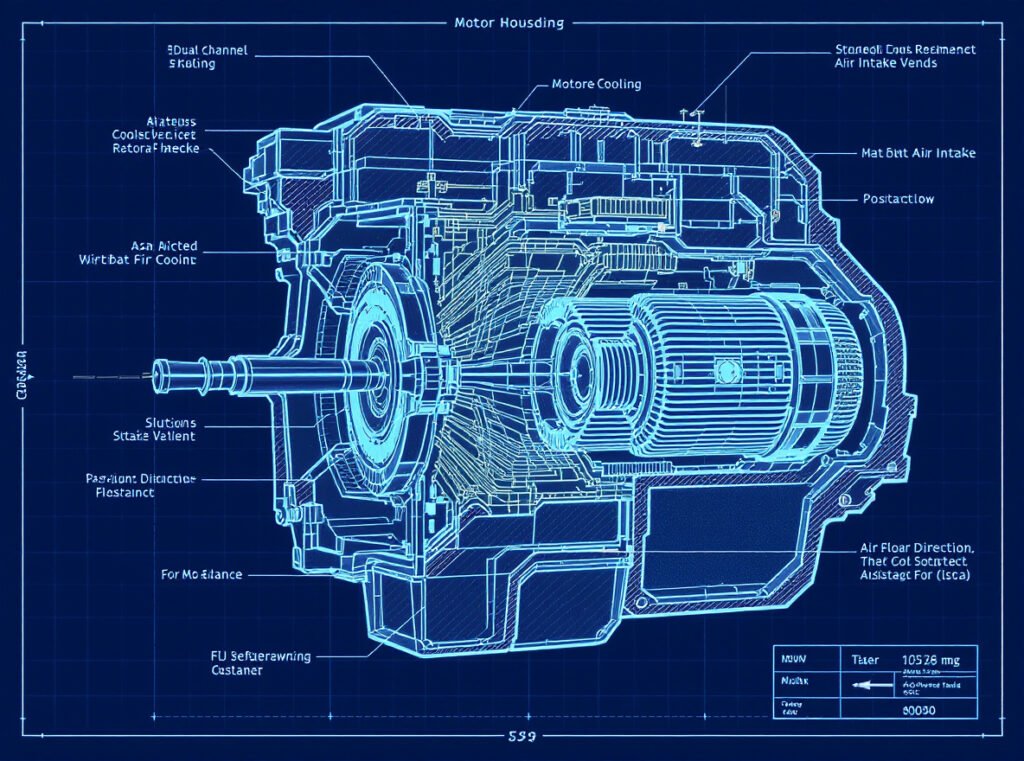

What Role Does Motor Housing Design Play in Airflow Optimization?

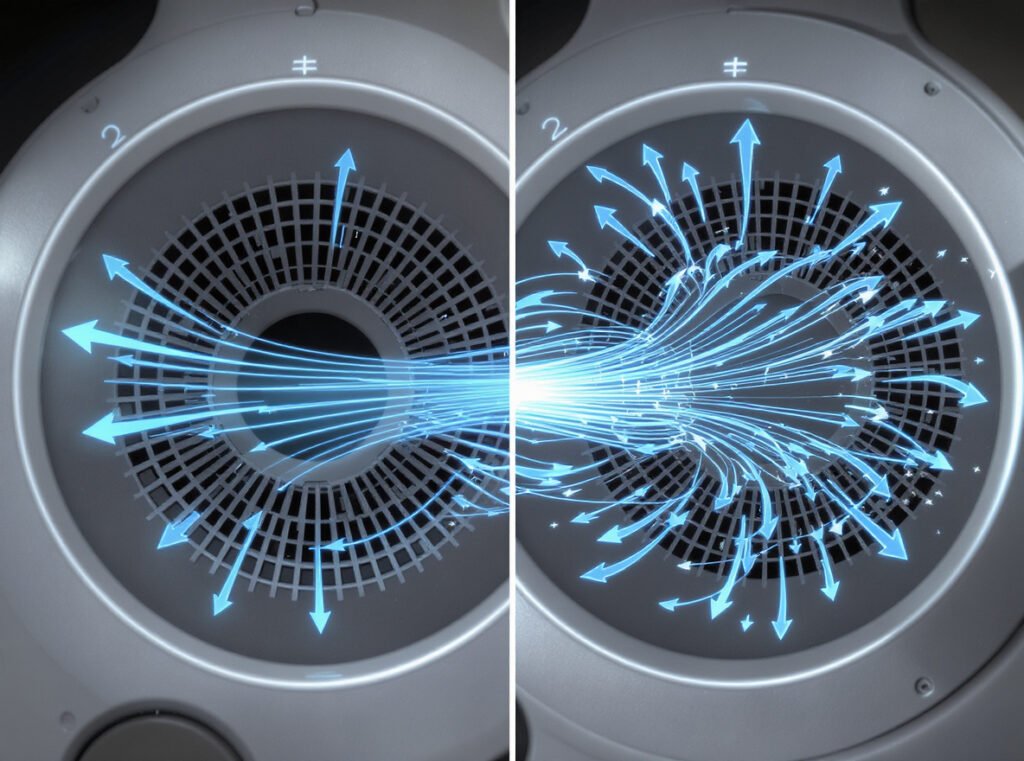

Motor housing configuration significantly impacts overall system performance by controlling initial air acceleration and managing the integration between motor output and airflow channels. This often-overlooked component determines fundamental airflow characteristics.

Motor housing design determines initial airflow characteristics by controlling air intake efficiency, managing pressure development, and creating optimal flow transitions. Strategic housing configuration reduces air resistance, improves motor cooling, and establishes the foundation for downstream airflow optimization.

Modern high-performance dryers revolutionize housing design for superior results:

Strategic Motor Positioning

Advanced designs position motors to maintain streamlined airflow paths. Revolutionary approaches like Dyson’s handle-mounted motor eliminate traditional top-heavy configurations, allowing air to flow more smoothly while improving ergonomic balance.

Dual-Channel Cooling Systems

Sophisticated housings incorporate separate cooling channels that prevent motor heat from affecting primary air stream temperature control. This design maintains consistent performance while protecting components from overheating.

Surface Engineering for Airflow

Premium housings feature smooth internal surfaces that reduce friction and turbulence, while strategic ribbing guides airflow in desired directions. Some incorporate noise-dampening materials without compromising airflow efficiency.

Key housing optimization features include:

- Multiple strategically positioned intake vents for maximum air volume

- Smooth internal geometries that minimize turbulence generation

- Advanced materials that maintain dimensional stability under thermal stress

- Integrated cooling systems that protect motor performance

Professional applications benefit significantly from optimized housing design, as consistent airflow performance directly impacts service quality and operational efficiency.

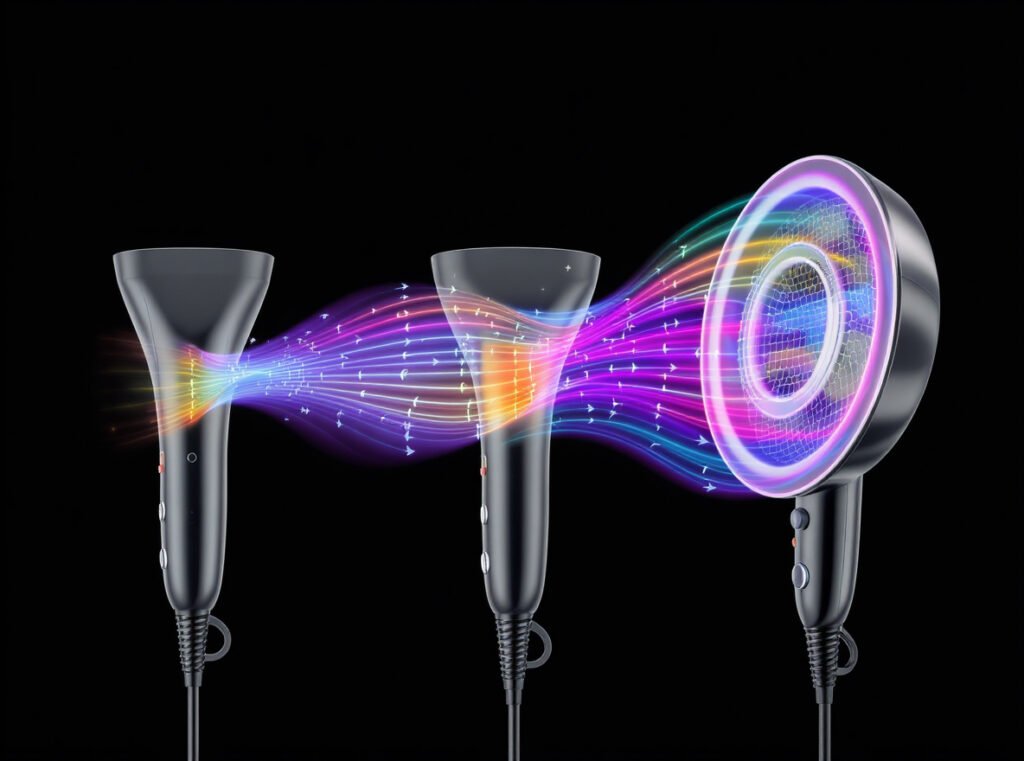

How Do Nozzle Attachments Transform Airflow Patterns?

Nozzle attachments serve as precision airflow control mechanisms, allowing users to customize air delivery patterns for specific styling requirements. Understanding attachment physics helps optimize drying and styling effectiveness.

Nozzle attachments transform airflow patterns by modifying exit velocity, air concentration, and flow direction characteristics. Concentrator nozzles focus airflow into high-velocity streams ideal for smoothing, while diffuser attachments disperse concentrated streams into multiple gentle currents that preserve natural curl patterns.

Different attachment types create distinct airflow transformations:

Precision Concentrator Technology

Concentrator nozzles narrow airflow to create focused, high-velocity streams that increase air speed while reducing coverage area. The concentrated airflow effectively lays hair cuticles flat, reducing frizz and providing precise sectional control.

Advanced Diffuser Systems

Diffuser attachments completely transform airflow characteristics by dispersing concentrated streams into multiple gentle air currents. The bowl-shaped design with extended prongs distributes airflow evenly around curls while the ventilated fingers separate hair sections for effective drying without pattern disruption.

Professional Comb Attachments

Specialized comb attachments combine airflow with mechanical action, using ventilated teeth to guide air directly through hair sections while simultaneously detangling. This proves particularly effective for textured or coarse hair requiring simultaneous smoothing and drying actions.

Magnetic Attachment Systems

Premium models utilize magnetic attachment systems that ensure optimal airflow alignment by maintaining precise positioning between attachments and the main body, eliminating air leakage that reduces performance.

The key to attachment effectiveness lies in maintaining the designed airflow characteristics while providing secure, leak-free connections that preserve intended performance parameters.

Why Does Internal Chamber Architecture Matter for Performance?

The internal chamber represents the critical zone where raw airflow transforms into heated, controlled air delivery. This hidden component significantly affects overall dryer performance through sophisticated engineering principles.

Internal chamber architecture matters because it controls heat transfer efficiency, air mixing uniformity, and temperature consistency. Optimal chamber design maintains laminar flow while accommodating heating elements without creating excessive turbulence, maximizing energy conversion from electrical heating to effective warm air output.

Several sophisticated design factors influence chamber performance:

Strategic Heating Element Integration

Advanced chamber designs position heating elements to maximize air contact without creating flow resistance. Segmented heating elements or alternative heating technologies minimize airflow disruption while maintaining effective heat transfer.

Pressure Differential Engineering

Sophisticated chambers use strategic shaping to create pressure differentials that enhance air acceleration, improving overall airflow efficiency without increasing power consumption.

Multi-Channel Air Management

High-end models incorporate multiple internal channels that separate heating and cooling air streams, enabling precise temperature and airflow control while protecting internal components.

Professional chamber design considerations include:

- Laminar flow maintenance through optimized geometry

- Strategic component positioning that minimizes airflow interference

- Advanced materials that withstand thermal stress while maintaining dimensional accuracy

- Integrated safety systems that protect performance while ensuring user safety

The chamber must balance multiple competing requirements – heat transfer efficiency, airflow preservation, component protection, and manufacturing feasibility – making it one of the most challenging aspects of professional dryer design.

How Does Overall Ergonomic Design Impact Airflow Effectiveness?

While ergonomics primarily addresses user comfort, design choices that improve handling directly influence how effectively airflow reaches intended targets. This relationship between form and function significantly affects real-world performance.

Ergonomic design impacts airflow effectiveness by enabling optimal positioning that maximizes air delivery accuracy and duration. Balanced weight distribution reduces user fatigue, allowing steady positioning that ensures airflow reaches intended hair sections rather than being misdirected due to handling difficulties.

Key ergonomic factors affecting airflow utilization:

Weight Balance and Distribution Engineering

Properly balanced designs allow users to maintain optimal angles for extended periods. When users can hold steady positions comfortably, more airflow energy reaches target areas rather than being wasted through misdirection caused by arm fatigue.

Handle Design and Control Precision

Strategic handle positioning affects directional control accuracy. Superior grip design enables precise airflow targeting, reducing energy waste and improving drying efficiency through better air placement.

Cord Management Systems

Well-engineered cord attachment points prevent interference with natural arm movements, allowing optimal dryer positioning for maximum airflow effectiveness.

Professional ergonomic benefits for commercial applications:

- Reduced operator fatigue enables longer service sessions and increased productivity

- Improved control precision results in more satisfied customers and better styling results

- Enhanced airflow utilization reduces energy consumption and service time

- Ergonomic design reduces repetitive strain injuries in high-volume professional settings

The Conason P1C incorporates professional-grade ergonomic engineering that enhances both operator comfort and airflow efficiency, making it ideal for demanding commercial environments where performance consistency matters most.

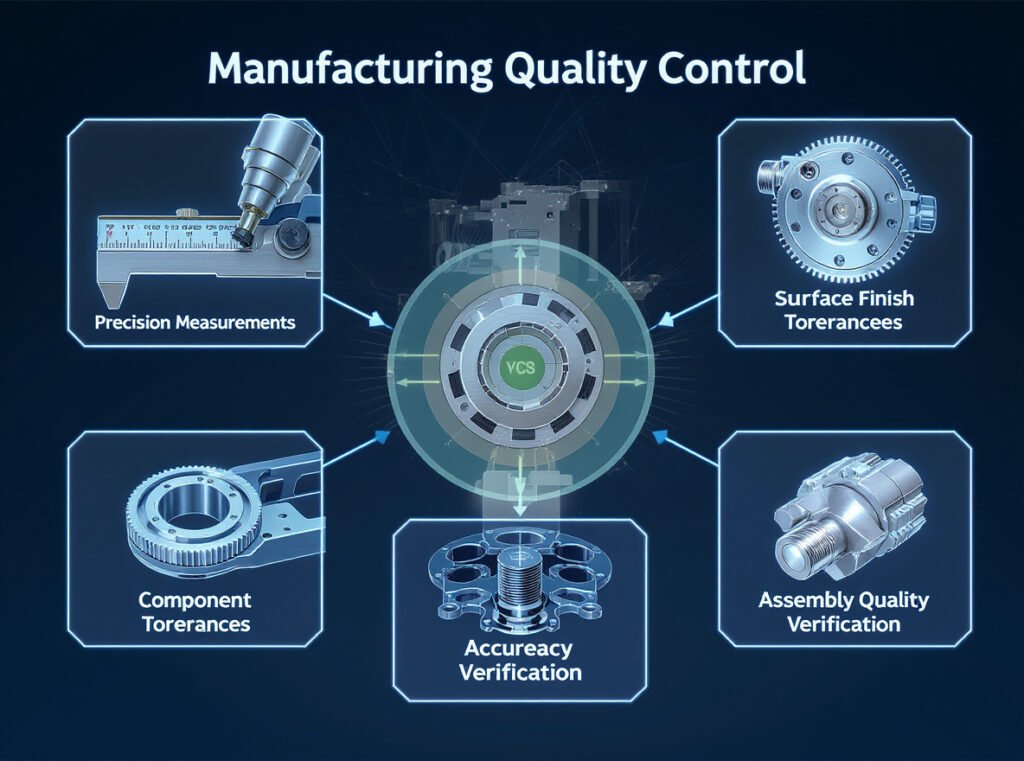

What Manufacturing Precision Affects Airflow Design Implementation?

Manufacturing processes and quality control standards significantly determine whether sophisticated airflow designs achieve their intended performance. Understanding these factors helps evaluate product consistency and long-term reliability.

Manufacturing precision directly affects airflow design through component tolerances, surface finish quality, and assembly accuracy. Precise manufacturing ensures consistent internal dimensions across production runs, smooth surfaces that minimize air resistance, and tight component integration that prevents air leakage and maintains designed airflow characteristics.

Critical manufacturing elements impacting airflow performance:

Advanced Material Selection

High-grade plastics and metals provide smooth internal surfaces that reduce air friction while maintaining dimensional stability under thermal stress. Premium materials preserve airflow characteristics throughout product lifespan.

Precision Molding and Assembly Standards

Tight manufacturing tolerances ensure consistent internal geometries across production runs. This precision guarantees that each dryer delivers designed airflow performance without unit-to-unit variation.

Comprehensive Quality Control Protocols

Rigorous testing during manufacturing identifies airflow inefficiencies before market delivery. This includes pressure testing, velocity measurements, and temperature distribution analysis to verify performance standards.

| Manufacturing Factor | Performance Impact | Quality Standard |

|---|---|---|

| Internal Dimension Tolerance | Consistent airflow patterns | ±0.05mm precision |

| Surface Finish Quality | Reduced air resistance | Ra < 1.2μm roughness |

| Component Integration | Zero air leakage | 100% pressure verification |

| Assembly Precision | Optimal airflow alignment | Automated quality testing |

For wholesale buyers, manufacturing quality directly correlates with:

- Consistent performance that builds customer confidence and repeat business

- Reduced warranty claims and service requirements

- Professional reputation enhancement through reliable product performance

- Long-term profitability through durable, high-performing inventory

Conason maintains industry-leading manufacturing standards that ensure every dryer delivers optimal airflow performance, providing wholesale partners with confidence in product quality and customer satisfaction.

Summary

Hair dryer body shape fundamentally controls airflow dynamics through sophisticated barrel engineering, motor housing optimization, internal chamber architecture, and ergonomic integration. These aerodynamic principles determine real-world performance far more than simple wattage specifications, making airflow design the critical factor for professional-grade effectiveness.

Ready to experience superior airflow engineering that delivers measurable performance advantages? Explore our professionally-engineered hair dryer collection at Conason Products or discover the advanced CFD-optimized airflow technology in our flagship P1C High-Speed Hair Dryer. Contact us today for wholesale inquiries and detailed technical specifications that demonstrate our commitment to airflow excellence.