If you’ve noticed your hair dryer’s casing becoming uncomfortably hot to touch, you’re facing a potentially serious safety issue that needs immediate attention. This overheating can damage your device, pose burn risks, and even create fire hazards if left unaddressed.

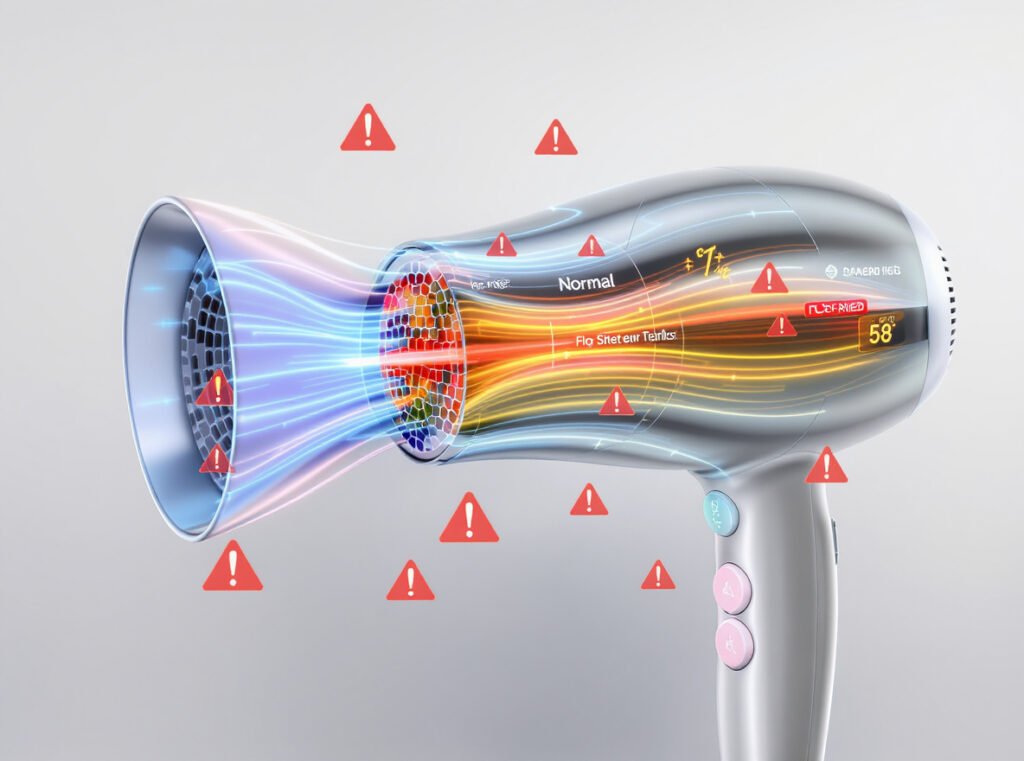

An overheating hair dryer casing typically indicates blocked air intake filters, motor or fan failures, defective heating element assembly, or faulty safety components like thermal fuses. The most common culprit is lint and debris accumulation in air intake vents, which restricts airflow and causes dangerous heat buildup in the housing. Professional hair dryers with brushless motors, multiple thermal sensors, and intelligent temperature monitoring can prevent these dangerous conditions.

Understanding why your hair dryer overheats and how to fix it will protect both your investment and your safety.

Table of Contents

ToggleWhat Are the Primary Causes of Hair Dryer Casing Overheating?

Hair dryer overheating stems from several critical system failures that disrupt the delicate balance between heat generation and proper cooling mechanisms.

The primary causes include blocked air intake filters from lint and hair accumulation, motor and fan component failures that reduce cooling airflow, faulty heating element assemblies that produce heat continuously, and defective safety components like thermal fuses and cycling thermostats. Each factor prevents proper heat dissipation, causing internal temperatures to rise to dangerous levels that transfer excessive heat to the outer casing.

Blocked Airflow – The Leading Culprit

When air intake filters become clogged with lint, hair, and styling product debris, hot air gets trapped inside the unit while preventing proper cooling air circulation. This blockage forces the heating element to work harder without adequate ventilation, creating a dangerous cycle where more heat is produced while less is being expelled.

The restriction causes internal temperatures to rise rapidly, triggering automatic safety shutoffs in modern devices. Without proper maintenance, this condition worsens progressively until the device becomes unsafe for continued use.

Motor and Fan System Failures

Motor problems create immediate overheating risks because insufficient air passes over the heating element to cool it down. When the fan motor fails or fan blades break, the heating element continues generating heat without adequate cooling airflow.

This creates dangerous situations where heating elements can glow red-hot while the motor struggles against increased resistance. Professional-grade devices with brushless motors experience fewer of these failures due to superior engineering and thermal management systems.

Heating Element and Safety Component Issues

| Component | Failure Mode | Result |

|---|---|---|

| Heating Element | Continuous heat production | Uncontrolled temperature rise |

| Thermal Fuse | Single-use component burns out | Loss of overheat protection |

| Cycling Thermostat | Fails to regulate temperature | No automatic temperature control |

| Bimetallic Strip | Loses sensitivity to heat | Delayed or absent shutoff response |

Malfunctioning heating elements may produce heat continuously even when proper temperature is reached, while failed safety components eliminate the device’s ability to automatically shut off during dangerous temperature spikes.

How Can I Recognize Warning Signs Before Dangerous Overheating Develops?

Early detection of overheating symptoms allows intervention before conditions become hazardous or cause permanent damage to your hair dryer.

Critical warning signs include noticeably reduced airflow even on high settings, increased drying time requiring significantly longer styling sessions, warm exterior housing that feels uncomfortably hot during normal operation, unusual noises like rattling or grinding sounds, and burning odors indicating overheating components. Advanced warning signs include automatic shutoffs due to thermal protection and excessive handle heat making the device uncomfortable to hold.

Early Performance Indicators

Pay attention to these subtle changes that signal developing problems:

- Airflow Reduction: Weaker air output compared to when the device was new indicates internal blockages or fan problems

- Extended Drying Time: Hair taking significantly longer to dry suggests reduced heating efficiency or airflow restrictions

- Temperature Changes: The plastic casing feeling warmer than usual during standard operation periods

- Sound Variations: New rattling, squealing, or grinding noises indicating mechanical component wear

Critical Safety Warnings

These symptoms require immediate attention and device discontinuation:

- Burning Odors: Any burnt smell indicates dangerous component overheating that poses fire risks

- Automatic Shutoffs: Unexpected device shutdowns during normal use show thermal protection systems activating

- Excessive Handle Heat: The grip area becoming too hot to hold comfortably signals heat transfer problems

- Visible Sparks or Smoke: Immediate signs of electrical system failure requiring emergency shutdown

Professional stylists recommend conducting weekly performance checks, especially for devices used daily in salon environments where safety is paramount.

What Emergency Steps Should I Take When My Hair Dryer Overheats?

When overheating occurs, immediate action prevents escalation into dangerous fire hazards or permanent equipment damage that could threaten user safety.

Emergency protocol requires immediately turning off and unplugging the device, allowing complete cooling for at least 20 minutes in a well-ventilated area, inspecting for visible damage like melted plastic or burnt components, and never attempting to continue using when burning smells, sparks, electrical arcing, or repeated shutoffs occur. These conditions indicate internal damage requiring professional assessment or device replacement.

Immediate Response Protocol

Follow this systematic approach when overheating is detected:

- Power Disconnection: Turn off and unplug immediately to prevent potential fire hazards and further internal damage

- Safe Placement: Move to heat-resistant surface away from flammable materials like towels, hair products, or paper

- Cooling Period: Allow minimum 20 minutes for complete temperature normalization before any handling

- Ventilation: Ensure adequate airflow around the device to disperse accumulated heat safely

- Damage Assessment: Inspect for melted plastic, discolored components, or damaged power cords

Never Continue Using When These Conditions Exist

Certain symptoms indicate immediate replacement necessity rather than attempted repairs:

- Persistent burning smells even after cooling periods

- Any visible sparks or electrical arcing during operation

- Repeated automatic shutoffs despite thorough cleaning maintenance

- Visible damage to housing, internal components, or power cords

- Handle areas that remain hot after normal cooling periods

Professional devices often include visual temperature indicators that help identify when cooling is complete and safe handling can resume.

How Should I Properly Clean and Maintain My Hair Dryer to Prevent Overheating?

Regular maintenance represents your most effective defense against hair dryer overheating while extending device lifespan and ensuring consistent safe operation.

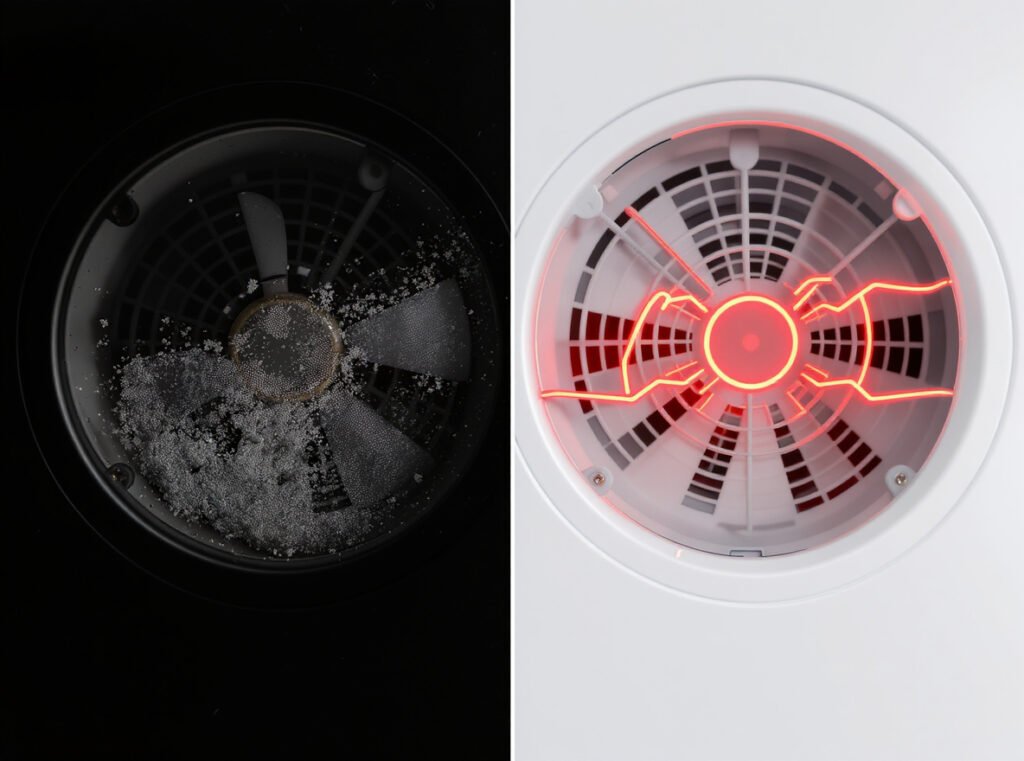

Effective maintenance includes monthly cleaning of removable air intake screens using soft brushes and vacuum suction, professional deep cleaning with soap solutions for thorough debris removal, proper storage practices avoiding cord damage, and regular inspection of safety components. Professional settings require weekly or even daily cleaning to prevent lint accumulation that creates fire hazards.

Monthly Filter Maintenance Routine

Start with device unplugged and completely cooled, then remove rear intake screens according to manufacturer instructions:

- Initial Cleaning: Use soft brush or vacuum attachment to remove surface lint buildup from mesh sections

- Deep Cleaning: Soak removable filters in warm soapy water solution (1/4 cup water with 5 drops dish soap)

- Thorough Rinse: Use cotton swabs with pure water to remove soap residue from detailed mesh areas

- Complete Drying: Allow 24 hours air drying before reinstallation to prevent moisture damage

Professional Maintenance Standards

Commercial and salon environments require more frequent maintenance due to intensive daily use:

| Usage Level | Cleaning Frequency | Maintenance Focus |

|---|---|---|

| Home Use | Monthly filter cleaning | Basic debris removal |

| Professional Daily | Weekly deep cleaning | Comprehensive system inspection |

| Salon/Commercial | Daily filter check | Immediate lint removal |

Professional maintenance includes inspecting internal components visible through air vents, checking power cord integrity throughout its length, and testing all switch functions for proper operation.

Storage and Handling Best Practices

Proper storage prevents many overheating issues while protecting internal components from damage:

- Cooling Requirements: Always ensure complete cooling before storage to prevent heat damage to storage areas

- Cord Management: Avoid wrapping cords tightly around devices, which damages internal wiring over extended periods

- Environmental Control: Store in dry, dust-free locations with adequate ventilation away from moisture sources

- Regular Inspection: Monthly power cord examination for cracks, kinks, or exposed internal wiring

What Advanced Safety Features Should I Prioritize in a Professional Hair Dryer?

Modern professional hair dryers incorporate multiple layers of safety technology that prevent overheating while maintaining optimal performance for intensive use applications.

Essential safety features include automatic thermal shutoff systems that activate around 140°F (60°C), thermal fuses providing permanent protection against fire hazards, multiple thermal sensors monitoring temperatures up to 1000 times per second, ALCI safety plugs preventing electrocution, and intelligent heat control systems that adjust temperature automatically. Professional-grade devices combine these features with brushless motors and heat-resistant housing for comprehensive protection.

Advanced Temperature Control Systems

Modern devices feature sophisticated monitoring that surpasses basic thermal protection:

- Intelligent Heat Monitoring: Premium models continuously monitor temperatures at multiple points, adjusting heat output automatically to prevent overheating while maintaining performance

- Multiple Heat Settings: Professional devices offer precise temperature control with at least three heat settings plus cool shot functions for different hair types

- Scalp Shield Technology: Advanced systems automatically adjust heat levels to protect sensitive skin while preventing component overheating

Critical Safety Component Integration

| Safety Feature | Function | Protection Level |

|---|---|---|

| Thermal Shutoff | Automatic power disconnection at preset temperatures | Prevents burns and component damage |

| Thermal Fuses | Permanent shutdown if excessive temperatures reached | Fire protection (single-use) |

| ALCI Safety Plugs | Ground-fault circuit interruption | Electrocution prevention |

| Heat-Resistant Housing | Insulated exterior materials | Reduces exterior temperature transfer |

| Multiple Thermal Sensors | Real-time temperature monitoring | Early warning and prevention |

Professional-Grade Construction Indicators

Quality devices demonstrate superior thermal management through design features like multiple air intake points for enhanced airflow, strategically placed exhaust vents for optimal heat dissipation, balanced weight distribution indicating quality internal components, and brushless motors that operate more efficiently with reduced heat generation.

For wholesale buyers and distributors, these features translate to reduced warranty claims, improved customer satisfaction, and enhanced brand reputation through superior safety standards.

When Should I Replace My Hair Dryer Rather Than Attempting Repairs?

Determining replacement versus repair depends on safety risks, economic factors, device age, and availability of modern safety features that weren’t present in older models.

Immediate replacement is required when safety hazards like sparks, burning smells, or visible damage are present, when devices over 5-6 years old experience frequent overheating despite maintenance, when repair costs exceed 50% of replacement value, or when repeated overheating persists after professional cleaning. Modern devices offer significantly improved safety features that older models cannot match through repairs.

Immediate Replacement Scenarios

Certain conditions indicate that repairs are unsafe and economically impractical:

- Safety Hazards: Any visible sparks, persistent burning smells, or electrical arcing requires immediate replacement rather than repair attempts

- Age Considerations: Hair dryers over 5-6 years old lack modern safety features like advanced thermal protection and intelligent monitoring systems

- Repeated Failures: Devices experiencing recurring overheating after thorough maintenance indicate fundamental design limitations

- Economic Thresholds: When professional repair estimates exceed 50% of quality replacement device costs

Repair Consideration Factors

Limited situations may justify professional repair services:

- Recent Purchase: Devices under 2-3 years old with isolated component failures may warrant repair if warranty coverage applies

- Simple Issues: Clogged filters, loose connections, or minor component replacements that don’t affect safety systems

- Professional Assessment: Qualified technician evaluation for internal wiring problems, motor failures, or recurring thermal fuse issues

Professional Safety Assessment Requirements

Consult qualified technicians when encountering:

- Internal electrical component failures that affect safety systems

- Motor or heating element problems that impact temperature regulation

- Recurring safety component failures indicating deeper system problems

- Any electrical safety concerns that pose fire or electrocution risks

What Are the Best Professional Hair Dryer Options for Preventing Overheating?

Selecting the right professional-grade hair dryer prevents overheating problems while providing reliable, safe operation that meets commercial use standards and regulatory requirements.

For optimal overheating prevention, prioritize devices with brushless motors, multiple thermal sensors, intelligent temperature monitoring, easy-clean removable filters, and comprehensive thermal protection systems. The Conason P1C high-speed hair dryer exemplifies professional-grade safety with advanced ionic technology, real-time temperature control, commercial-grade thermal protection, and user-friendly maintenance features designed for intensive professional applications.

Professional-Grade Safety Technology

The Conason P1C high-speed hair dryer incorporates comprehensive overheating prevention technologies:

- Advanced Thermal Management: Multiple temperature sensors provide continuous monitoring with automatic adjustment capabilities

- Commercial Safety Standards: Professional-grade thermal cutoff systems exceed residential device protection levels

- Intelligent Control Systems: Digital temperature display and memory functions prevent user error that leads to overheating

- Easy Maintenance Design: Removable filters and accessible components facilitate regular cleaning that prevents blockages

- Brushless Motor Technology: Superior efficiency reduces heat generation while providing consistent airflow under intensive use

Professional Feature Comparison

Modern professional devices incorporate advanced safety technologies that surpass basic consumer models:

| Technology | Benefit | Professional Application |

|---|---|---|

| Brushless Motors | Reduced heat generation, longer lifespan | Intensive salon use without overheating |

| Ionic Technology | Faster drying reduces continuous operation time | Minimizes heat exposure periods |

| Multiple Thermal Sensors | Real-time temperature monitoring and adjustment | Prevents overheating during long styling sessions |

| Professional Certifications | UL or CE safety compliance | Meets commercial insurance requirements |

Wholesale and Distributor Considerations

For businesses serving professional markets, stocking devices with comprehensive safety features provides multiple advantages:

- Reduced Warranty Claims: Advanced thermal protection minimizes customer complaints and returns

- Professional Market Appeal: Safety certifications and commercial-grade features attract salon and beauty school customers

- Brand Reputation Protection: Superior safety standards build customer loyalty and reduce liability concerns

- Training and Support: Comprehensive safety features include user education materials that reduce support calls

Professional buyers can explore our complete collection of commercial-grade hair dryers with advanced safety features at https://conason.com/product/ to find solutions that meet specific market requirements and safety standards.

Contact our wholesale team to discuss bulk orders, professional training programs, and partnership opportunities that prioritize customer safety while meeting commercial performance requirements.

Summary

Hair dryer casing overheating results from blocked air filters, motor failures, faulty heating elements, and defective safety components that disrupt proper cooling systems. Early warning signs like reduced airflow, unusual sounds, and automatic shutoffs allow intervention before dangerous conditions develop. Regular maintenance with monthly filter cleaning, proper storage practices, and professional-grade devices with advanced thermal protection systems effectively prevent overheating while ensuring safe operation.

For wholesale buyers, distributors, and retailers seeking reliable professional hair dryers with comprehensive overheating prevention, explore our commercial-grade solutions designed with brushless motors, multiple thermal sensors, and easy maintenance requirements that meet intensive use standards while prioritizing user safety.