Nothing’s more frustrating than reaching for your hair dryer, only to discover it’s blowing cold air instead of the warm heat you need. This common issue can disrupt your morning routine and leave you with damp, unstyled hair.

A hair dryer typically blows only cold air due to heating element failure, blown thermal fuse activation, or thermostat malfunction. These components can fail from overheating, dust buildup, or normal wear after 3-5 years of regular use.

Let’s explore the specific causes and solutions to get your hair dryer working properly again.

Table of Contents

ToggleWhat Are the Primary Causes of Cold Air Problems?

Understanding the root causes helps you determine whether simple maintenance can fix the issue or if component replacement is necessary.

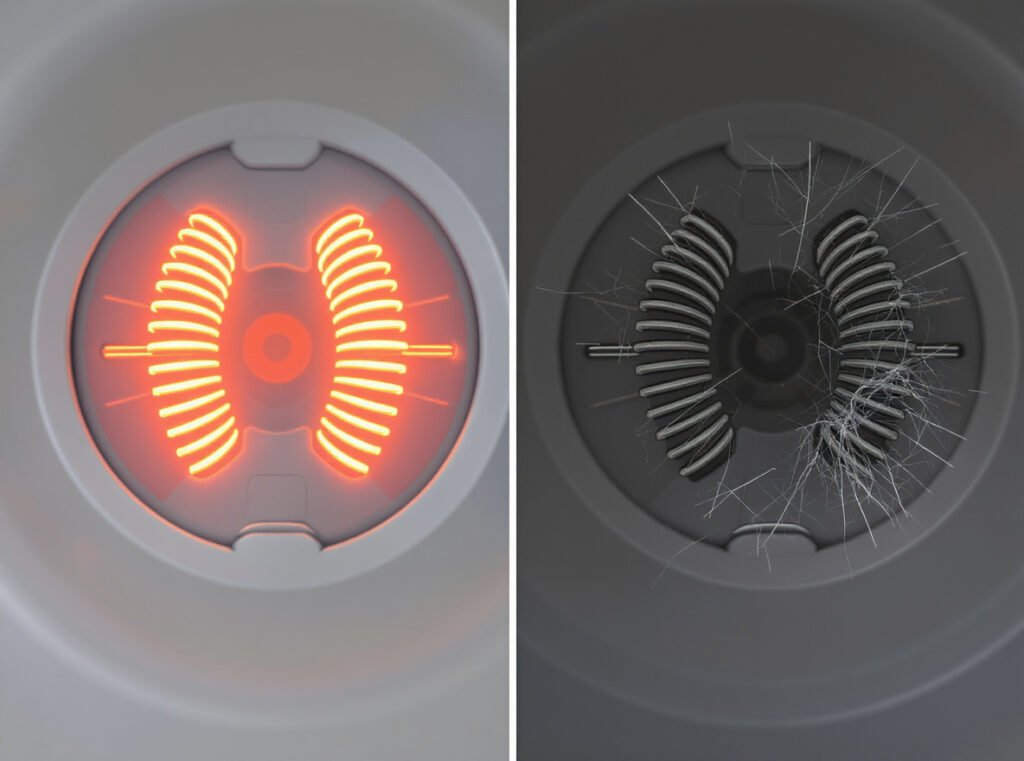

Heating element failure represents the most common cause of cold air issues. The heating element consists of coiled wires that generate heat when electricity passes through them, but these elements can develop breaks or disconnections over time.

Heating Element Failure

The heating element contains coiled wires that heat up when electricity flows through them. These coils can develop cracks, burns, or complete breaks, particularly at connection points where vibration and heat cycling cause metal fatigue.

Thermal Safety System Activation

Modern hair dryers include thermal cutoff switches (thermal fuses) that automatically disconnect power to the heating element when temperatures exceed safe limits. Once activated, these safety devices prevent fires but result in cold air output until the fuse is replaced.

Thermostat Malfunction

When thermostats fail to properly control heat output, they may default to cold air as a safety measure. Faulty thermostats can become stuck in the “off” position, preventing the heating element from receiving power entirely.

| Component | Function | Typical Failure Signs |

|---|---|---|

| Heating Element | Generates warm air through electrical coils | Visible cracks, burns, or severed wires |

| Thermal Fuse | Prevents overheating damage | Complete loss of heat function |

| Thermostat | Controls temperature regulation | Inconsistent heating or cold air only |

Internal Wiring Issues

Loose connections, damaged wires, or corroded terminals can interrupt power flow to the heating element. These electrical problems often develop from vibration, heat cycling, or manufacturing defects that worsen over time.

Switch Problems

Cold shot buttons can become stuck in the activated position, keeping the dryer locked in cold air mode. Even when the button appears to function normally, internal switch mechanisms may prevent return to heating operation.

How Can I Diagnose and Fix These Problems?

Most cold air issues can be identified through systematic troubleshooting before considering professional repair or replacement.

Start with basic checks: ensure proper heat settings, verify the cold shot button isn’t engaged, and allow 15-20 minutes cooling time if overheating is suspected. These simple steps resolve many temporary heating issues immediately.

Basic Troubleshooting Steps

Check Settings and Controls

Verify you’ve selected the correct heat setting and that no cold shot features are accidentally engaged. Many modern dryers have multiple temperature options that can be easily confused.

Allow Thermal Reset

Unplug your dryer for 15-20 minutes to allow thermal protection systems to reset completely. This simple step resolves temporary overheating protection activation in many cases.

Visual Inspection

Examine the unit for obvious damage including cracked housing, damaged cords, or visible debris blocking air vents. Look for burn marks or unusual discoloration around the heating area.

Advanced Diagnostic Methods

Continuity Testing

Using a multimeter, test the heating element for electrical continuity between terminals. A reading of zero or near-zero ohms indicates proper function, while infinite resistance suggests element failure.

- Test thermal fuses for continuity to determine if they’ve blown

- Check internal wiring connections for loose or corroded contacts

- Measure resistance across thermostat terminals in different positions

Component Replacement Options

Thermal fuses cost $5-15 and can often be replaced by users with basic electrical skills. Heating elements typically cost $20-50 but require extensive disassembly and technical knowledge for safe installation.

Is Repair Worth It or Should I Replace My Hair Dryer?

The decision between repair and replacement depends on your dryer’s age, repair costs, and reliability requirements for your specific application.

Professional repairs typically cost $50-150 in parts plus labor. For consumer-grade dryers under $100, replacement often proves more economical than repair, especially when major components fail.

Cost Analysis Framework

The 50% Rule

If repair costs exceed 50% of a new unit’s price, replacement typically offers better value. Basic hair dryers cost $20-100, while professional models range from $100-400, making repair economics highly variable.

Age and Usage Considerations

Hair dryers typically last 3-5 years with regular consumer use, or 1-2 years under professional salon conditions. Units approaching their expected lifespan should generally be replaced rather than repaired.

Professional vs. Consumer Grade Economics

Consumer Models ($20-100)

- Heating element replacement: $50-80 including labor

- Often not cost-effective to repair major components

- Limited warranty coverage (typically 1 year)

Professional Models ($100-400)

- Higher repair costs justified by replacement expense

- Better component quality extends repair worthiness

- Extended warranty coverage (2-10 years available)

For businesses serving multiple clients daily, investing in professional-grade equipment ensures consistent performance and reduces costly downtime from equipment failures.

What Quality Factors Should Wholesalers Consider?

Understanding manufacturing quality control and common failure points helps wholesalers, distributors, and retailers make informed purchasing decisions.

Leading manufacturers employ comprehensive testing protocols including noise tests, wind speed measurements, ion count verification, and running endurance tests with quality control teams of 40+ inspectors ensuring international standards compliance.

Manufacturing Quality Indicators

Component Durability Standards

Professional-grade units use ceramic or tourmaline heating elements that resist wear and provide consistent temperature control over thousands of hours. These advanced materials distribute heat more evenly, reducing hot spots that cause traditional coil failures.

Safety System Reliability

Advanced thermal protection systems include multiple sensors that continuously monitor temperature, preventing overheating without completely disabling the unit. Modern designs allow quick recovery once temperatures normalize.

International Compliance Requirements

Reputable suppliers maintain certifications including UL approval, FCC compliance, and IEC 61855 standard adherence. This international testing standard specifies comprehensive performance requirements including drop endurance tests and service life evaluations.

| Quality Factor | Consumer Grade | Professional Grade | Business Impact |

|---|---|---|---|

| Heating Elements | Basic wire coils | Ceramic/Tourmaline | 3-5x longer lifespan |

| Thermal Protection | Single fuse system | Multi-stage sensors | Prevents total failure |

| Motor Type | Brushed motors | Brushless technology | Reduced maintenance |

| Warranty Coverage | 1 year | 2-10 years | Lower replacement costs |

Supply Chain Risk Management

Quality Control Verification

Request detailed quality management documentation including material sourcing processes, production control methods, and defect prevention protocols. Third-party test reports provide independent verification of performance claims.

Counterfeit Product Identification

“Dupe” products pose significant safety risks including inadequate electrical insulation, substandard materials, and missing safety features like immersion protection devices. Verify authentic supplier relationships and proper certification documentation.

How Do Modern Technology Advances Improve Reliability?

Recent innovations have significantly reduced traditional failure points while improving overall performance and safety standards.

Brushless motors eliminate carbon brush wear, reduce maintenance needs, provide quieter operation, and offer longer service life compared to traditional brushed motors while delivering more consistent airflow.

Advanced Safety Features

Multi-Level Protection Systems

Contemporary hair dryers incorporate automatic shut-off mechanisms, GFCI protection for water exposure, thermal sensors with continuous monitoring, and improved thermal fuse designs with better reliability ratings.

Intelligent Temperature Control

Microprocessor-controlled systems measure air temperature multiple times per second, preventing overheating and heat damage while maintaining optimal styling temperatures automatically.

Performance Technology Integration

High-Speed Motor Benefits

Advanced fan designs with brushless motors reduce drying time by 30-50%, minimizing thermal stress on internal components and extending overall lifespan through reduced operational hours.

Ionic and Ceramic Technologies

These systems provide more even heat distribution, reduce hot spots, and improve energy efficiency while decreasing component wear through optimized thermal management.

The Conason P1C incorporates these advanced technologies including brushless motor systems, intelligent heat control, and multi-stage thermal protection designed specifically for commercial reliability and consistent professional performance.

Energy Efficiency Improvements

- Infrared heating systems reduce energy consumption while maintaining performance

- Optimized airflow designs minimize motor strain and heat buildup

- Advanced materials improve thermal efficiency and component longevity

- Smart power management reduces operational costs over equipment lifetime

What Maintenance Practices Prevent Heating Problems?

Proactive maintenance significantly extends hair dryer lifespan and prevents unexpected heating failures in both consumer and commercial environments.

Regular cleaning of air vents and filters prevents overheating that causes thermal fuse activation and heating element damage. Establishing maintenance schedules reduces equipment replacement costs by up to 60%.

Professional Maintenance Protocols

Daily Cleaning Routine

Remove visible hair and lint from intake and exhaust vents after each day’s use. This simple step prevents 80% of overheating issues in high-usage environments like salons.

Weekly Deep Cleaning

Use compressed air to clear internal air pathways where dust accumulation typically occurs. Focus on areas around the heating element and thermal sensors for optimal performance.

Monthly Performance Monitoring

Test temperature consistency across all heat settings and monitor for unusual noises or reduced airflow that indicate developing problems before complete failure occurs.

Smart Equipment Management

For businesses requiring consistent performance, maintain backup units to avoid service interruptions and track usage hours to anticipate component wear schedules. Consider rotating equipment to distribute wear evenly across multiple units.

Professional Service Scheduling

Quarterly professional cleaning and inspection for high-usage environments identifies potential issues before they cause equipment failure, extending operational life significantly.

Ready to upgrade your inventory with reliable, professional-grade hair dryers? Our advanced P1C model features brushless motor technology, intelligent thermal control, and comprehensive safety systems designed for commercial applications. Visit conason.com/product/conason-negative-ionic-fast-hair-dryer-with-screen-home-salon-use-p1c/ to learn more about professional-grade reliability.

Summary

Hair dryers blowing cold air typically result from heating element failure, thermal fuse activation, or thermostat malfunction caused by overheating or component wear. While basic troubleshooting and thermal fuse replacement can resolve some issues, professional-grade equipment offers superior reliability through advanced safety systems and quality components.

Explore our complete collection of professional hair dryers at conason.com/product/ or contact our wholesale team to discuss bulk pricing and distribution opportunities for reliable commercial equipment.