You’ve invested in a premium hair dryer, expecting consistent performance, but it keeps pulsing on and off intermittently. This frustrating issue disrupts your styling routine and makes you question whether your expensive investment was worth it.

High-end hair dryers pulse on and off due to thermal protection system activation, which monitors internal temperatures and automatically cycles the unit when overheating is detected to prevent damage and ensure user safety.

Understanding the science behind this protective behavior and learning proper maintenance techniques can restore your dryer’s performance and prevent future issues.

Table of Contents

ToggleWhat Causes High-End Hair Dryers to Pulse Intermittently?

When your premium hair dryer starts cycling on and off, it’s not a malfunction—it’s actually a sophisticated safety feature working to protect both you and the device. However, frequent pulsing indicates underlying issues that need attention.

The primary cause of pulsing in premium hair dryers is thermal overload protection triggered by blocked air intake, restricted airflow, internal component wear, or high ambient temperatures that force thermal sensors to activate automatic shutdown cycles.

Understanding Thermal Overload Triggers

Blocked Air Intake Issues

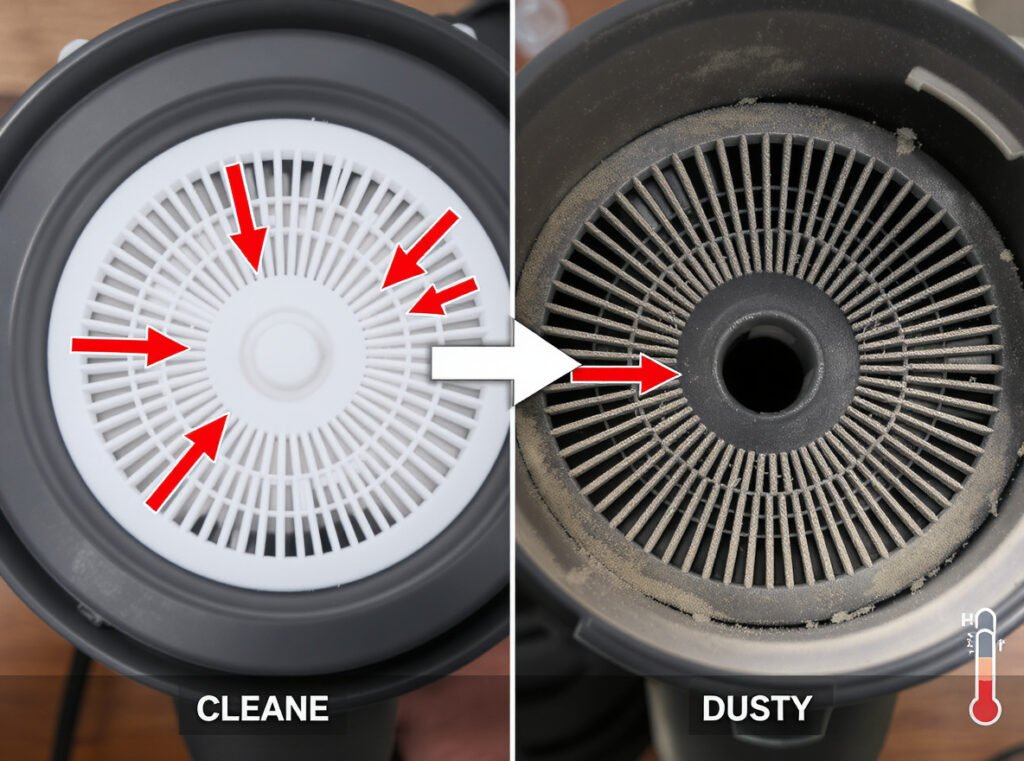

The most common culprit behind pulsing behavior is a clogged or dirty filter. Dyson hair dryers pull air through rear filters that accumulate dust, lint, and debris over time. When airflow becomes restricted, the motor works harder and generates excess heat that triggers protection systems.

Airflow Restriction Problems

- Hair dryer placement too close to surfaces during use

- Intake accidentally covered by hands or styling accessories

- Internal air pathways blocked by accumulated debris

- Exhaust vents obstructed during operation

Component Degradation Factors

- Motor bearing wear creating increased friction and heat

- Heating element efficiency decline over time

- Electrical resistance buildup in aging components

- Internal dust accumulation reducing cooling effectiveness

| Common Trigger | Heat Buildup Time | Protection Response |

|---|---|---|

| Blocked filter | 2-3 minutes | Automatic cycling every 30-60 seconds |

| Covered intake | 1-2 minutes | Immediate shutdown with reset attempts |

| Worn bearings | 5-10 minutes | Intermittent pulsing with longer cooling periods |

How Do Thermal Protection Systems Work in Premium Hair Dryers?

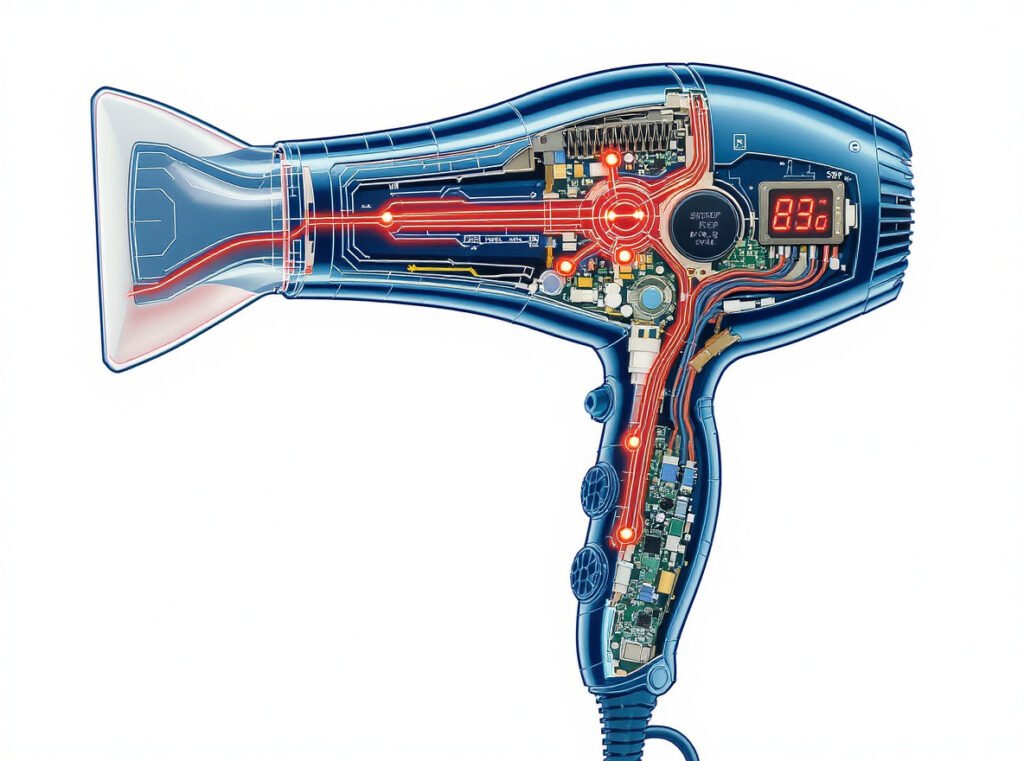

Modern high-end hair dryers incorporate multiple layers of sophisticated thermal protection that go far beyond basic safety switches, using advanced monitoring and control systems to maintain optimal operation.

Premium hair dryers use thermal cutoff switches, smart temperature monitoring that checks heat levels up to 200 times per second, automatic reset cycles, and motor protection systems that work together to prevent overheating damage.

Advanced Safety Architecture

Multi-Layer Protection Systems

High-end models feature thermal cutoff switches as temperature-sensitive devices that automatically interrupt power when internal temperatures exceed safe limits. Some are one-time use thermal fuses, while others reset automatically when temperatures normalize.

Advanced models incorporate smart temperature monitoring technology. The TYMO AirHype, for example, features T-sensor smart temperature control that monitors heat output 200 times per second to prevent overheating and hair damage.

Automatic Reset Mechanisms

When thermal protection activates, the dryer typically shuts off for a cooling period, then automatically attempts to restart once internal temperatures normalize. This creates the characteristic pulsing pattern users observe.

Motor-Specific Protection

- Brushless motors include dedicated thermal protection circuits

- Temperature sensors monitor motor housing heat levels

- Automatic power reduction before complete shutdown

- Progressive cooling cycles to extend component lifespan

Smart Control Integration

Modern dryers coordinate multiple protection systems simultaneously, balancing performance with safety through intelligent algorithms that learn usage patterns and adjust protection thresholds accordingly.

When Should You Be Concerned About Pulsing?

Not all pulsing indicates serious problems requiring immediate professional attention. Learning to distinguish between normal protective cycling and genuine malfunctions helps you respond appropriately and avoid unnecessary service costs.

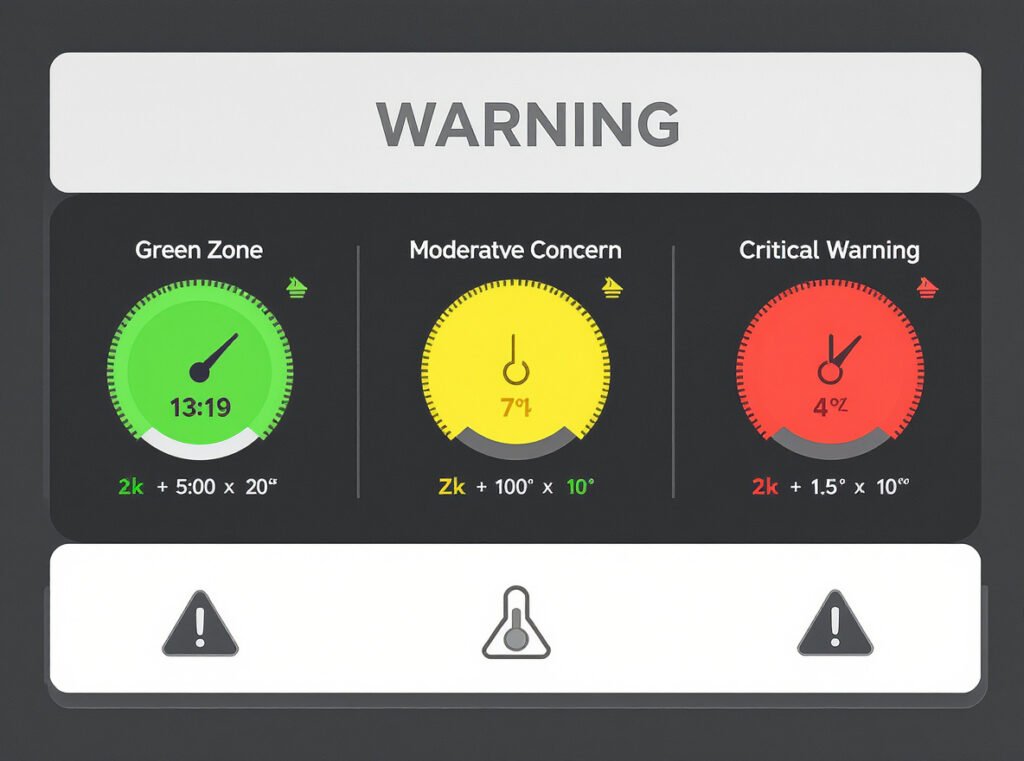

Immediate concern is warranted when pulsing occurs within the first minute of use, accompanies burning smells or unusual noises, shows continuous flashing lights, or fails to reset after proper cooling periods.

Critical Warning Signs vs. Normal Operation

Immediate Attention Required:

- Pulsing within 60 seconds on new or recently cleaned dryers

- Burning odors or visible smoke during operation

- Red or white indicator lights flashing continuously

- Grinding, squealing, or rattling mechanical noises

- Complete failure to restart after cooling periods

Normal Thermal Cycling Patterns:

- Occasional pulsing after 15+ minutes of continuous high-heat use

- Brief shutdowns followed by successful restarts

- Cycling frequency that decreases in cooler environments

- Consistent airflow when unit is operating

Environmental Factors Affecting Performance:

Using dryers in hot, humid environments or immediately after other heat-generating styling tools contributes to faster thermal buildup and more frequent protection activation.

| Symptom | Severity Level | Recommended Action |

|---|---|---|

| Pulsing after 15+ minutes use | Normal | Allow cooling break, continue use |

| Pulsing within 5 minutes | Moderate | Clean filters, check ventilation |

| Burning smell with pulsing | Critical | Stop use immediately, seek service |

What Immediate Steps Can Fix Pulsing Issues?

Before assuming your expensive hair dryer needs professional repair, systematic troubleshooting can resolve most thermal protection issues and restore normal operation without costly service calls.

Immediate fixes include complete power down and cooling for 30 minutes, checking ALCI safety plug reset buttons, thoroughly cleaning air intake filters, clearing all air pathways, and testing in optimal environmental conditions.

Systematic Troubleshooting Protocol

Step 1: Complete System Reset

Unplug the dryer immediately when pulsing begins and allow complete cooling for at least 30 minutes. This allows all thermal protection systems to reset naturally and provides baseline performance testing.

Step 2: Safety System Reset

Many hair dryers feature ALCI (Appliance Leakage Circuit Interrupter) safety plugs with reset buttons. Press the red reset button on the plug if present, ensuring proper electrical connection before testing.

Step 3: Professional Filter Cleaning

- Remove air intake filters according to manufacturer instructions

- Use soft brush or old toothbrush for surface debris removal

- For Dyson models specifically: use clarifying shampoo and rinse for 20 seconds

- Ensure filters are completely dry before reinstallation

Step 4: Comprehensive Airway Inspection

- Check all air vents for visible obstructions

- Verify intake and exhaust areas remain clear during use

- Remove any hair or debris wrapped around internal components

- Test airflow strength at various heat settings

Step 5: Optimal Environment Testing

Test the dryer in a cool, well-ventilated area using the lowest heat setting to determine if thermal issues persist under ideal conditions.

How Can You Prevent Future Pulsing Problems?

Implementing proper maintenance schedules and usage practices significantly reduces thermal protection activation while extending your premium hair dryer’s operational lifespan and maintaining consistent performance levels.

Prevention requires weekly filter cleaning for heavy use, proper usage practices that avoid blocking air intakes, environmental considerations for optimal operating conditions, and professional maintenance for high-value units.

Comprehensive Maintenance Strategy

Filter Maintenance Schedule:

Clean filters weekly for heavy daily use, monthly for occasional use. Professional salon environments should clean filters twice weekly to maintain optimal airflow and prevent thermal buildup.

Daily Usage Best Practices:

- Keep air intakes completely unobstructed during operation

- Use appropriate heat settings matched to your specific hair type

- Allow 2-3 minute cooling periods during extended styling sessions

- Maintain constant dryer movement rather than concentrating heat

Environmental Optimization:

- Operate in well-ventilated areas whenever possible

- Avoid immediate use after other heat-generating styling tools

- Consider ambient temperature and humidity impacts on performance

- Store in cool, dry locations away from dust accumulation

Professional Care Protocols:

For high-end units worth $300+, consider annual professional cleaning and inspection, especially for salon use or daily home styling routines.

| Maintenance Task | Frequency | Performance Impact |

|---|---|---|

| Filter cleaning | Weekly (heavy use) | 40% thermal load reduction |

| Professional service | Annually | 25% lifespan extension |

| Proper storage | After each use | Prevents dust accumulation |

When Should You Consider Professional Repair or Replacement?

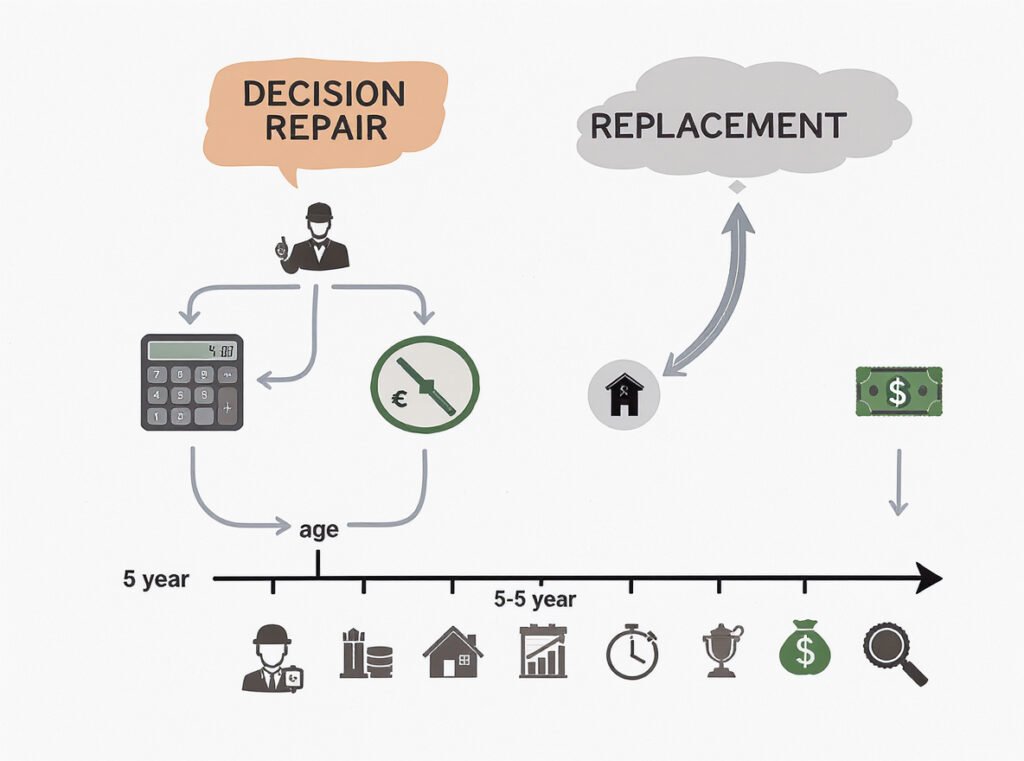

Making informed decisions about professional service versus replacement requires understanding repair economics, safety considerations, and the expected lifespan of premium hair styling equipment.

Professional repair becomes necessary when pulsing persists after thorough maintenance, unusual mechanical noises develop, visible component damage occurs, or safety systems fail to reset properly regardless of cooling periods.

Economic and Safety Decision Framework

Repair Viability Indicators:

- Persistent thermal issues after comprehensive cleaning

- Units under 5 years old with good overall condition

- Single-system failures rather than multiple component problems

- Professional diagnosis confirming repairable issues

Replacement Considerations:

Hair dryers typically last 5-8 years with proper maintenance. Units over 5-6 years old with regular use likely need replacement rather than repair investment.

Cost-Benefit Analysis:

Professional repairs typically range from $100-400, while replacement units vary from $50-600 depending on features and quality. For premium models like Dyson (original cost $300-500), repairs under $200 may be worthwhile if the unit is less than 5 years old.

Safety Priority Situations:

If thermal protection systems fail to reset properly or the unit shows signs of electrical issues, immediate replacement is recommended regardless of age or cost considerations.

For businesses seeking reliable alternatives to problematic high-end dryers, the Conason P1C high-speed hair dryer incorporates advanced thermal protection with T-sensor technology monitoring temperatures continuously. Our professional-grade models offer superior reliability for commercial applications while maintaining the premium features your customers expect.

Summary

High-end hair dryer pulsing typically results from thermal protection systems correctly preventing overheating damage through automatic cycling. Most issues resolve through proper maintenance, environmental optimization, and systematic troubleshooting. When problems persist despite comprehensive care, professional evaluation determines the most cost-effective solution for your investment.

Looking for reliable hair dryer solutions that eliminate thermal protection issues? Explore our professional-grade collection at Conason Products or discover the advanced temperature monitoring features of our P1C High-Speed Hair Dryer designed for consistent commercial performance. Contact our wholesale team to discuss bulk pricing and distribution opportunities for superior alternatives to problematic premium dryers.