The pet grooming industry is experiencing unprecedented growth, with professional salons demanding equipment that can handle high-volume operations. However, sourcing the wrong equipment can devastate your business reputation and customer relationships. Finding reliable private-label pet grooming dryers requires strategic evaluation of multiple critical factors.

High-quality private-label pet grooming dryers should feature professional-grade motors (2,100-2,800W power with 200+ CFM airflow), ETL/UL/CE safety certifications, variable speed controls, thermal protection, noise reduction below 78dB, and comprehensive customization options. Evaluate manufacturers based on ISO certification, production capacity, quality control systems, and 1-2 year warranty coverage.

Let’s explore the essential criteria that will help you make informed sourcing decisions and build a successful private-label pet grooming equipment business.

Table of Contents

ToggleWhy Is Motor Power and Performance Critical for Professional Pet Grooming Dryers?

Professional grooming businesses demand equipment that can handle high-volume operations without compromising efficiency. Motor specifications directly impact your customers’ productivity and profitability in busy salon environments.

Professional pet grooming dryers require motors with 2,100-2,800W power output, airflow above 200 CFM, variable speed controls up to 60,921 FPM, and dual high-speed motors (20,000+ RPM) for maximum efficiency. These specifications ensure rapid water removal across all coat types while reducing drying time for high-volume operations.

The motor serves as the heart of any professional grooming dryer. Understanding power requirements helps you evaluate whether a manufacturer can deliver equipment that meets professional standards for busy salons processing multiple dogs daily.

High-powered motors directly correlate with faster drying times, which is essential for professional groomers managing tight schedules. Variable speed and heat controls address different breeds and coat thicknesses while reducing pet stress and preventing coat damage.

Key Motor Specifications for Professional Use:

- Power Output: 2,100-2,800W for professional-grade performance

- Airflow Capacity: 200+ CFM for blaster models, 230+ CFM for premium units

- Speed Range: Variable control up to 60,921 FPM for different coat types

- Motor Configuration: Dual motor systems for enhanced durability and power

Noise levels significantly impact both pet comfort and staff working conditions. Quality dryers maintain noise levels below 78dB while delivering maximum performance, reducing pet anxiety and supporting staff health during extended use.

| Motor Feature | Professional Standard | Key Benefits |

|---|---|---|

| Power Output | 2,100-2,800W | Faster drying, reduced session time |

| Airflow Capacity | 200-245 CFM | Efficient water removal, versatile performance |

| Speed Control | Variable up to 60,921 FPM | Adaptable to coat types, reduced pet stress |

| Noise Level | Below 78dB | Pet comfort, staff health protection |

How Important Are Safety Features and Certifications for B2B Pet Grooming Equipment?

Safety certifications and built-in protection features distinguish professional-grade equipment from consumer products. Your customers’ businesses depend on equipment that protects both animals and operators while meeting regulatory requirements.

Professional pet grooming dryers must include ETL, UL, CSA, or CE certifications, thermal overload protection, ground fault circuit interrupters (GFCI), immersion protection, and heat-insulated construction. These certifications are often mandatory for commercial insurance coverage and business licensing compliance.

Safety features directly impact your customers’ insurance costs, regulatory compliance, and business reputation. Professional groomers face strict liability requirements and cannot afford equipment-related incidents that could result in business closure or legal issues.

Equipment failures or safety incidents can result in severe financial consequences and regulatory violations. Professional groomers work with nervous animals in wet environments, making comprehensive safety features essential for maintaining controlled, professional operations.

Essential Safety Certifications and Features:

ETL, UL, CSA, and CE certifications demonstrate compliance with electrical and product safety standards, building buyer trust and meeting mandatory requirements for commercial operations. These certifications are often required for business insurance and professional licensing.

Thermal and overload protection systems provide automatic shut-off capabilities to prevent overheating and fire hazards. Ground fault and immersion protection reduces electrical shock risks, which are mandated for commercial hand-held dryers in many regions.

Critical Safety Requirements:

- Electrical Certifications: ETL, UL, CSA, CE compliance for commercial use

- Thermal Protection: Automatic shut-off prevents overheating and equipment damage

- GFCI Integration: Essential protection against electrical shock in wet environments

- Heat-Insulated Construction: Double-wall nozzles and insulated hoses for safe operation

- Overload Protection: Circuit protection prevents electrical fires and equipment damage

What Customization Options Should You Expect from Private-Label Manufacturers?

Private-label success depends on creating distinctive products that differentiate your brand in competitive markets. Comprehensive customization capabilities determine your ability to build unique market positioning and meet specific regional requirements.

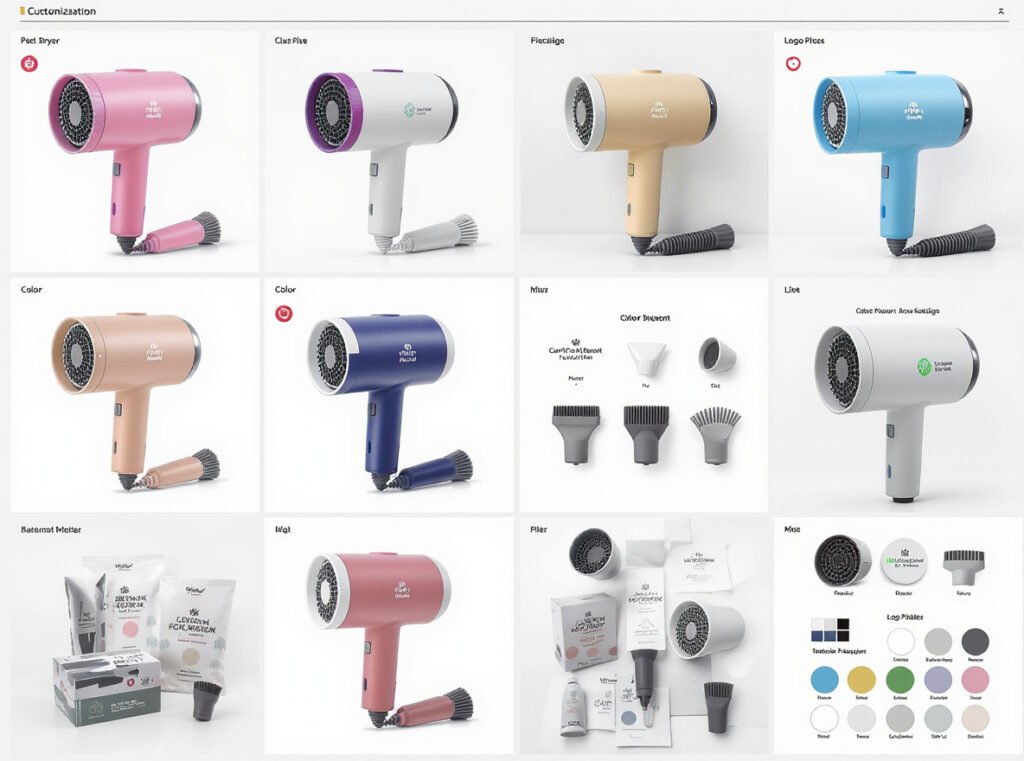

Quality private-label manufacturers should offer branding customization (logos, labels, custom colors), motor specifications (single/dual motor options, voltage variations), attachment configurations, packaging design, regulatory labeling for different regions, and OEM formulation options. Some manufacturers also provide marketing support and custom documentation.

Customization extends beyond superficial branding to include functional modifications that align with specific market requirements. Different regions may require different electrical specifications, certifications, or feature sets to meet local regulations and customer preferences.

Comprehensive Customization Categories:

Visual branding options include logo placement, custom labels (engraved or printed), multiple body colors, and decorative decals. These elements help establish brand recognition and professional appearance in competitive markets.

Functional customization addresses motor options (variable power settings, single or dual motor configurations), voltage requirements for different regions, and specialized attachment configurations to meet specific grooming needs.

Available Customization Options:

- Branding Elements: Logos, custom labels, color schemes, decorative finishes

- Motor Configurations: Power settings, dual motor options, voltage specifications

- Attachment Systems: Nozzle varieties, hose configurations, storage solutions

- Packaging Solutions: Retail-ready boxes, eco-friendly materials, branded inserts

- Documentation: Custom manuals, multilingual instructions, training materials

- Regulatory Compliance: Region-specific certification marks and safety labels

| Customization Type | Standard Options | Premium Options |

|---|---|---|

| Visual Branding | Logo placement, basic colors | Custom housing design, premium finishes |

| Motor Specifications | Power adjustments, voltage options | Dual motor systems, specialized controls |

| Packaging | Branded boxes, basic inserts | Complete retail packaging, promotional kits |

| Documentation | Branded manuals, basic instructions | Multilingual materials, video tutorials |

How Do You Evaluate Manufacturing Quality and Production Capabilities?

Manufacturing quality directly impacts product reliability, customer satisfaction, and long-term business success. Thorough evaluation prevents costly quality issues, warranty claims, and supply chain disruptions that can damage your brand reputation.

Evaluate manufacturers through ISO, GMP, BSCI, or HACCP certifications, documented quality assurance systems with batch testing protocols, pre-production sample validation, factory audit capabilities, and verified monthly production capacity. Request detailed SOPs, traceability records, and batch-to-batch consistency documentation.

Quality assessment requires examining both manufacturing processes and final product testing procedures. Professional manufacturers implement systematic quality management approaches with documented standard operating procedures and regular QA audits.

Manufacturing scale and flexibility directly affect your ability to meet market demands and scale operations. Verify monthly production capacity, lead times, and the manufacturer’s ability to adjust production volumes based on changing business requirements.

Quality Evaluation Framework:

Production facilities should maintain clean, organized environments with modern equipment for precision assembly and automated testing. Quality manufacturers invest in comprehensive testing equipment and maintain detailed quality records for traceability.

Request detailed information about materials sourcing, supplier qualifications, component testing procedures, and final inspection protocols. Understanding the complete supply chain helps predict potential quality or delivery issues before they impact your business.

Manufacturing Assessment Criteria:

- Quality Certifications: ISO, GMP, BSCI, HACCP, or equivalent standards

- Documentation Systems: Detailed SOPs, batch testing records, traceability protocols

- Sample Validation: Pre-production samples, batch-to-batch consistency verification

- Audit Capabilities: On-site or third-party inspection opportunities

- Production Capacity: Verified monthly output, scalability, lead time management

- Supply Chain Control: Reliable component sourcing, inventory management systems

What After-Sales Support Should You Expect from Your Manufacturer?

After-sales support significantly impacts your customers’ satisfaction and your brand reputation. Comprehensive support services differentiate professional suppliers from basic product vendors and directly affect long-term customer relationships.

Professional manufacturers should provide standard 1-2 year warranties (premium options up to 4 years), in-house or authorized repair centers, easy replacement parts ordering, responsive customer service with clear escalation paths, comprehensive documentation, and flexible return/replacement policies for defective units.

After-sales support extends your manufacturer relationship beyond initial product delivery. Strong support services help you maintain customer relationships, resolve issues quickly, and build brand loyalty in competitive markets.

Customer service quality directly affects your ability to resolve equipment issues during peak business periods when professional groomers cannot afford extended downtime. Responsive communication and clear RMA processes are essential for maintaining customer satisfaction.

Comprehensive Support Services:

Warranty coverage should include protection against manufacturing defects with clear terms and conditions. Premium manufacturers often offer extended warranty options that demonstrate confidence in product quality and provide additional value to end customers.

Repair and parts services require accessible service centers, transparent repair processes, and readily available replacement components. Some manufacturers provide on-site repair options or expedited depot services for critical business equipment.

Expected Support Components:

- Warranty Coverage: Standard 1-2 years, premium options up to 4 years

- Repair Services: In-house or authorized centers, clear RMA procedures

- Parts Availability: Easy ordering, competitive pricing, fast shipping

- Customer Service: Multiple contact channels, quick response times

- Documentation: Comprehensive manuals, troubleshooting guides, online resources

- Technical Support: Phone/email assistance, video consultation options

How Do You Assess Pricing Structure and Total Cost of Ownership?

Pricing evaluation requires analyzing total cost of ownership rather than focusing solely on initial purchase prices. Hidden costs and long-term expenses can significantly impact profitability and customer satisfaction over the equipment lifecycle.

Evaluate total costs including base unit pricing, bulk order discounts, shipping and customs duties, maintenance expenses, power efficiency costs, warranty benefits, and product longevity factors. Calculate TCO as: (Initial Cost + Maintenance/Repair + Shipping/Duties + Energy Use) minus (Discounts + Warranty Benefits).

Pricing transparency indicates manufacturer professionalism and helps you plan accurate budgets for inventory and customer pricing strategies. Hidden fees or unexpected costs can destroy profit margins and damage customer relationships.

Long-term cost considerations include maintenance requirements, replacement parts costs, energy efficiency, and equipment lifespan. Some manufacturers offer trade-in programs or upgrade incentives that reduce total ownership costs for repeat customers.

Total Cost of Ownership Analysis:

Base unit pricing should reflect actual value delivered through quality, features, and support services. Bulk order discounts can significantly reduce per-unit costs, but require careful inventory planning and cash flow management.

Energy efficiency affects ongoing operational costs based on motor wattage and typical usage patterns. Higher-efficiency motors may justify premium pricing through reduced electricity costs over the equipment lifecycle.

Cost Analysis Framework:

- Base Unit Costs: Core pricing, volume discounts, payment terms

- Shipping and Duties: Delivered costs including customs, insurance, logistics

- Maintenance Expenses: Parts costs, service frequency, repair accessibility

- Energy Efficiency: Ongoing electricity costs based on wattage and usage

- Warranty Value: Coverage duration, included services, claim procedures

- Product Longevity: Expected lifespan, replacement frequency, upgrade pathways

| Cost Category | Typical Range | Primary Factors |

|---|---|---|

| Base Unit Price | $300-1,200 | Power, features, certifications |

| Shipping/Duties | 10-25% of unit cost | Distance, order size, customs |

| Annual Maintenance | 5-15% of purchase price | Build quality, usage intensity |

| Energy Costs | $50-200 annually | Wattage, efficiency, usage hours |

What Compliance and Certification Requirements Should You Verify?

Regulatory compliance protects your business from legal issues, ensures product safety for end users, and meets mandatory requirements for commercial operations. Different markets require specific certifications and documentation for legal sale and operation.

Verify manufacturers provide electrical safety certifications (ETL, UL, CSA, CE, FCC), environmental compliance documentation (RoHS, REACH), business licensing support, animal welfare guideline adherence, and proper import/export documentation with certificates of origin and safety reports for cross-border trade.

Compliance requirements vary significantly between markets and regions. Professional manufacturers should understand and accommodate different regulatory environments for international distribution while maintaining current certifications for major markets.

Missing certifications can prevent product sales, create liability issues, require expensive retrofitting, or result in regulatory violations. Professional groomers often face strict licensing requirements that mandate certified equipment for legal operation.

Essential Compliance Areas:

Electrical safety certifications ensure products meet local electrical codes and safety standards. These certifications are typically required for commercial sale and operation in developed markets and affect insurance coverage.

Environmental compliance addresses material restrictions, disposal requirements, and environmental impact documentation. Many regions restrict certain materials or require specific environmental certifications for commercial equipment.

Required Certification Categories:

- Electrical Safety: ETL, UL, CSA, CE, FCC certifications for target markets

- Environmental Standards: RoHS, REACH compliance, material safety documentation

- Business Licensing: Support for professional licensing and permit requirements

- Animal Welfare: Adherence to animal handling and welfare guidelines

- Import/Export: Customs documentation, certificates of origin, safety reports

- Quality Standards: ISO certifications for manufacturing processes and quality management

How Do You Evaluate Manufacturer Reliability and Business Stability?

Manufacturer reliability affects your ability to maintain consistent supply chains, quality standards, and customer service over the long term. Partnership stability becomes critical for building successful private-label businesses and maintaining customer relationships.

Assess manufacturer reliability through business registration verification, years of operation (minimum 5-10 years preferred), customer references and case studies, industry certifications, facility ownership status, financial stability indicators, transparent business practices, and multi-year warranty offerings with domestic service capabilities.

Business stability directly impacts your supply chain reliability, quality consistency, and long-term partnership potential. Unstable manufacturers create risks for inventory availability, quality control, and ongoing support services that can damage your business reputation.

Due diligence helps identify potential red flags before committing to significant orders or long-term agreements. Professional manufacturers welcome scrutiny and provide transparent business information, customer references, and facility documentation.

Reliability Assessment Framework:

Years of operation and industry experience indicate business stability and market knowledge. Established manufacturers with 5-10+ years of relevant experience typically demonstrate better understanding of customer needs and quality requirements.

Customer references provide crucial insights into actual performance, relationship management, and support quality. Speaking directly with existing customers reveals information about delivery reliability, quality consistency, and service responsiveness.

Evaluation Criteria:

- Business History: Years in operation, industry experience, growth trajectory

- Financial Stability: Facility ownership, business registration, operational indicators

- Customer References: Testimonials, case studies, direct customer feedback

- Industry Standing: Trade association memberships, awards, certifications

- Service Capabilities: Domestic service centers, warranty support, technical assistance

- Transparency: Open documentation, facility tours, production information

| Reliability Indicator | What to Look For | Risk Mitigation |

|---|---|---|

| Years of Operation | 5-10+ years minimum | Established market presence |

| Customer References | Verifiable testimonials | Direct performance validation |

| Certifications | Current quality/safety standards | Compliance assurance |

| Service Network | Domestic support centers | Local service availability |

| Financial Stability | Owned facilities, stable operations | Supply chain reliability |

Summary

Sourcing high-quality private-label pet grooming dryers requires comprehensive evaluation of motor specifications (2,100-2,800W power, 200+ CFM airflow), safety certifications (ETL/UL/CE), customization capabilities, manufacturing quality (ISO certification), support services (1-2 year warranties), transparent pricing, regulatory compliance, and manufacturer reliability. Focus on established partners who demonstrate professional capabilities and long-term business stability for maximum success.

Ready to source professional pet grooming dryers for your business? Explore Conason’s comprehensive selection of high-performance dryers and grooming equipment at conason.com/product. Our P1C high-speed hair dryer features professional-grade performance perfect for pet grooming applications. Contact our team for customized private-label solutions, competitive wholesale pricing, and dedicated B2B support tailored to your business needs.