Water and electrical appliances don’t mix, and hair dryers are no exception. Whether it’s an accidental drop into the bathtub or a splash from the sink, water exposure can create serious safety hazards and permanently damage your hair dryer.

When a hair dryer gets submerged in water, it can cause electrical shock, electrocution, short circuits, and immediate device failure. The risk exists whether the device is on or off, as long as it remains plugged in, because water conducts electricity and can electrify the surrounding area.

Don’t risk your safety or waste money on repairs. Keep reading to understand the full consequences of water exposure and how to protect your investment in quality hair styling equipment.

Table of Contents

ToggleWhat Happens Immediately When a Hair Dryer Hits Water?

The moment a hair dryer contacts water creates a dangerous electrical situation that demands immediate attention and proper emergency response.

If a plugged-in hair dryer falls into water, there’s an immediate risk of electrical short circuit, sparks, overheating, fire, or electrocution. Water conducts electricity from the device into the surrounding area, creating life-threatening hazards regardless of whether the device is switched on or off.

Plugged-In Scenarios

When a connected hair dryer hits water, several dangerous events occur simultaneously. The water becomes electrified, carrying current throughout the wet area and creating severe shock risks for anyone nearby. Circuit breakers or GFCI outlets may trip to cut power, but this protection isn’t guaranteed to activate before dangerous exposure occurs.

Unplugged Device Outcomes

Even unplugged hair dryers suffer significant damage when submerged. Water penetrates internal components, reaching the motor, electrical circuits, and heating elements. While immediate electrocution risk is eliminated, the device becomes unsafe for future use due to internal moisture and component damage.

Emergency Response Timing

The first few seconds after water contact are critical. Never attempt to grab a plugged-in hair dryer from water with bare hands. Instead, immediately shut off power at the circuit breaker or use a dry, non-conductive tool to disconnect the device safely.

For wholesale buyers and retailers, understanding these immediate risks helps you educate customers about proper hair dryer handling and emphasizes the importance of safety features in quality devices like our P1C high-speed hair dryer.

Can You Still Use a Hair Dryer After Water Exposure?

Many people wonder if their hair dryer can be salvaged after getting wet, but safety experts strongly advise against attempting to use water-damaged devices.

It is not recommended to use a hair dryer after water exposure, even if it appears dry externally. Hidden moisture inside can cause short circuits, corrosion, or electrical hazards. Using a water-damaged hair dryer poses extreme danger and may result in malfunction, shock, or electrocution.

Hidden Moisture Dangers

Even when external surfaces appear completely dry, moisture can remain trapped inside the device for weeks. This internal dampness causes gradual corrosion of electrical components, reduces insulation effectiveness, and creates unpredictable failure points during operation.

Corrosion and Component Failure

Water exposure initiates immediate corrosion processes that continue long after the visible water disappears. Metal components oxidize, electrical connections deteriorate, and safety systems become compromised. These changes make the device unreliable and potentially dangerous.

Professional Assessment Requirements

If you’re considering keeping a water-exposed hair dryer, professional inspection is essential. However, most repair technicians recommend replacement rather than attempted restoration due to the extensive internal damage that water exposure typically causes.

| Risk Factor | Immediate Effect | Long-Term Consequence |

|---|---|---|

| Internal Moisture | Hidden water retention | Ongoing corrosion, component failure |

| Electrical Circuits | Short circuit potential | Unpredictable power delivery |

| Safety Systems | Compromised protection | Increased shock and fire risk |

| Motor Components | Bearing damage | Mechanical failure during use |

For businesses stocking hair dryers, this reality emphasizes the importance of offering reliable models with enhanced water protection features to minimize customer losses from accidental exposure incidents.

How Long Does It Take for Water Damage to Ruin a Hair Dryer?

The timeline for water damage varies significantly depending on the extent of exposure and immediate response actions taken.

Water damage can cause immediate failure if a short circuit occurs during submersion. However, even if the device seems functional after drying, hidden moisture can lead to corrosion, reduced efficiency, or eventual breakdown over days or weeks.

Immediate Failure Scenarios

When a plugged-in hair dryer contacts water, short circuits can occur within seconds, causing immediate and permanent damage. Electrical components may burn out instantly, motors can seize, and safety systems may fail catastrophically.

Progressive Damage Timeline

- 0-24 Hours: Water penetrates internal components, begins corrosion processes

- 1-7 Days: Moisture spreads throughout electrical systems, insulation begins deteriorating

- 1-4 Weeks: Hidden corrosion becomes extensive, components fail unpredictably

- Beyond 1 Month: Even apparently functional devices show reliability issues

Drying Time Requirements

Complete internal drying can take several days to weeks, depending on environmental conditions and device construction. However, even thorough drying cannot reverse corrosion damage or restore compromised electrical insulation.

Hidden Damage Persistence

The most dangerous aspect of water damage is its invisible nature. A hair dryer may appear to function normally for days or weeks after exposure, then suddenly fail during use, creating safety hazards and potential injury risks.

This unpredictable failure pattern explains why quality manufacturers like Conason invest heavily in water-resistant design features and robust safety systems in products like our P1C high-speed hair dryer.

What Are the Safety Risks of Using a Water-Damaged Hair Dryer?

Using a water-damaged hair dryer creates multiple serious safety hazards that persist even after the device appears dry and functional.

Safety risks include electrical shock, electrocution, short circuits, fire hazards, malfunctioning heating elements, sparks, and overheating. These dangers persist even if the device looks dry or appears to function normally after water exposure.

Electrical Hazards

Water-damaged hair dryers pose severe electrical risks including shock and electrocution. Compromised insulation creates unpredictable current paths, while corroded connections can deliver dangerous voltage levels to external surfaces that users regularly touch.

Fire and Overheating Risks

Damaged electrical components generate excessive heat at failure points, potentially igniting internal materials or surrounding objects. Short circuits can produce sparks that ignite lint, hair, or other combustible materials commonly found in bathrooms.

Mechanical Failures

Water-damaged motors may fail suddenly during operation, causing:

- Unexpected shutdowns that can cause burns from hot surfaces

- Mechanical breakage that can create sharp edges or projectiles

- Overheating that can damage hair or cause scalp burns

- Inconsistent airflow that affects styling effectiveness

Toxic Emission Risks

When damaged components overheat, they can release harmful fumes from:

- Burning plastic housing materials

- Overheated motor windings

- Corroded metal components

- Damaged insulation materials

| Risk Category | Immediate Danger | Severity Level | Prevention |

|---|---|---|---|

| Electrical Shock | Burns, cardiac arrest | Critical | Immediate disposal |

| Fire Hazard | Property damage, injury | High | Professional inspection |

| Mechanical Failure | Cuts, burns | Moderate | Avoid use entirely |

| Toxic Emissions | Respiratory damage | Moderate | Ventilation, disposal |

For retailers and distributors, these comprehensive safety concerns highlight the importance of educating customers about water damage risks and offering hair dryers with advanced safety features.

How Much Does It Cost to Replace vs. Repair a Water-Damaged Hair Dryer?

The financial analysis of water-damaged hair dryers consistently demonstrates that replacement offers better value than attempting repairs.

Professional repair costs typically range from $50-200 for basic models, potentially reaching $800 for complex issues or premium brands. Replacement costs range from $600-1,500 for high-end models. If repair costs exceed half the price of a new unit, replacement is generally recommended.

Repair Cost Breakdown

Professional hair dryer repair involves multiple cost factors:

- Diagnostic assessment fees: $25-50

- Water damage evaluation: $30-75

- Component replacement costs: $40-150

- Labor charges: $50-100 per hour

- Parts availability and shipping: $20-50

Replacement Cost Analysis

New hair dryer prices vary significantly based on features and quality:

- Basic consumer models: $30-80

- Mid-range professional units: $100-300

- Premium salon-grade dryers: $300-600

- Commercial wholesale units: $50-200 per unit

Hidden Repair Costs

Beyond direct repair expenses, consider additional factors:

- Reduced reliability and shortened lifespan

- Voided manufacturer warranties

- Continued safety risks and liability concerns

- Potential for repeat water damage incidents

Wholesale Business Considerations

For retailers and distributors, repair costs become even less attractive when considering:

- Customer satisfaction and return policies

- Liability issues from selling repaired electrical devices

- Inventory management complications

- Brand reputation risks

| Cost Factor | Repair Option | Replacement Option |

|---|---|---|

| Initial Investment | $50-800 | $30-1,500 |

| Warranty Coverage | None | Full manufacturer warranty |

| Reliability Expectation | Questionable | Guaranteed performance |

| Safety Assurance | Compromised | Complete safety features |

| Long-term Value | Poor | Excellent |

This cost analysis supports recommending replacement over repair to customers, while emphasizing the value of investing in quality, water-resistant models that minimize future water damage risks.

What Should You Do If Your Hair Dryer Gets Wet?

When water exposure occurs, following proper emergency procedures can prevent injury and minimize electrical system damage.

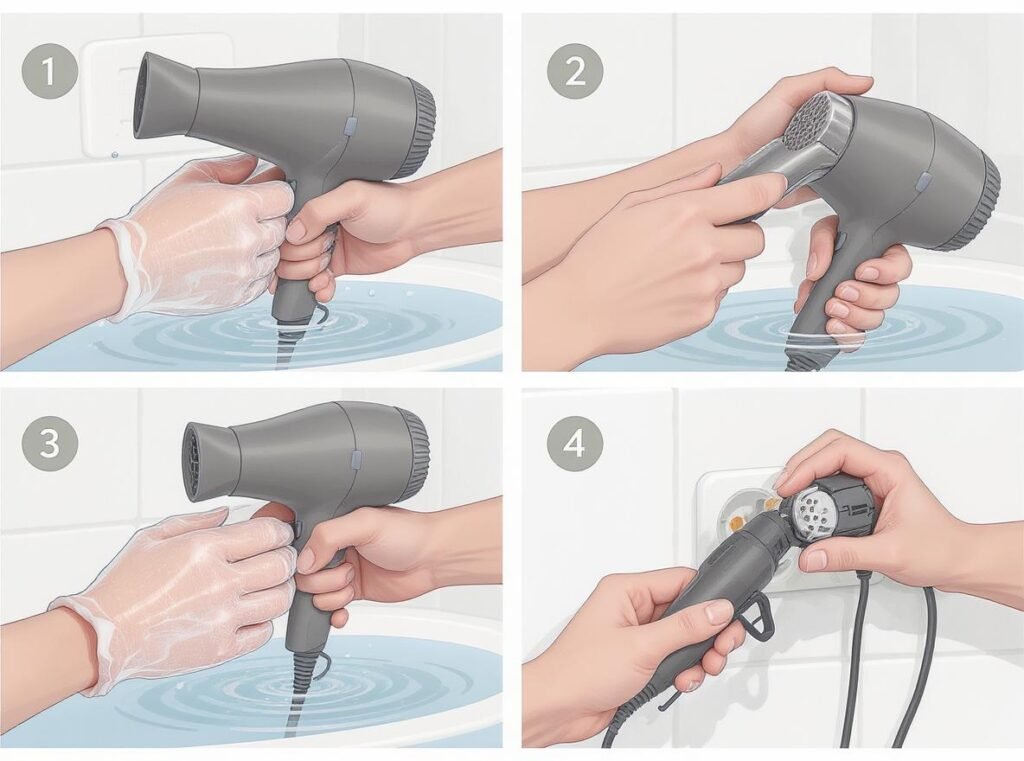

If your hair dryer gets wet, immediately unplug it without touching the device while it’s in water. Remove it using dry, insulated tools, dry the exterior thoroughly, and let it air dry for several days. Never use the device until professional inspection, and consider safe disposal to avoid safety risks.

Emergency Response Steps

- Immediate Power Disconnection: Unplug the hair dryer immediately, or shut off power at the circuit breaker if the device remains in water

- Safe Removal Process: Use dry, insulated hands or non-conductive tools to remove the device from water

- Secure Drying Location: Place the hair dryer on a dry surface in a warm, well-ventilated area

- Professional Assessment: Contact a qualified technician for safety evaluation before considering future use

Critical Safety Precautions

Never attempt these dangerous actions:

- Touching a plugged-in device while it’s in water

- Using heat sources to accelerate drying

- Testing the device “just to see” if it works

- Disassembling the unit without proper training

Proper Drying Procedures

If you choose to attempt drying (not recommended for safety reasons):

- Remove all visible water from external surfaces

- Allow air drying in a warm, dry location for several days

- Ensure complete internal moisture evaporation

- Avoid enclosed storage during drying process

Professional Disposal Guidelines

The safest approach involves proper disposal:

- Contact local electronics recycling programs

- Check manufacturer take-back initiatives

- Ensure safe removal from household electrical systems

- Consider environmental disposal requirements

This incident provides an excellent opportunity to upgrade to a superior hair dryer with enhanced safety features. Our P1C high-speed hair dryer includes advanced protection systems designed to minimize water damage risks while delivering professional-quality results for your customers.

Can Modern Hair Dryers Survive Water Exposure Better?

Recent advances in hair dryer technology have introduced improved safety features, though complete water protection remains challenging to achieve.

Some modern hair dryers feature improved safety technologies like ground fault circuit interrupters (GFCIs) and immersion sensors that cut power when submerged. However, not all models include these protections, and water exposure still poses significant risks requiring complete avoidance.

Advanced Safety Technologies

Modern professional-grade hair dryers incorporate several protective features:

- Immersion Detection Systems: Sensors that automatically shut off power when water contact is detected

- Enhanced GFCI Integration: Faster electrical disconnection to prevent electrocution

- Improved Housing Seals: Better resistance to water penetration in critical areas

- Automatic Shutoff Mechanisms: Systems that prevent operation when moisture is detected

Limitations of Current Technology

Even advanced models face significant challenges:

- Complete submersion can overwhelm most protection systems

- Prolonged water exposure eventually causes component failure

- Safety features may prevent immediate injury but cannot prevent internal damage

- Economic factors still strongly favor replacement over repair attempts

Professional Grade Advantages

Commercial-quality hair dryers offer superior protection:

- Reinforced electrical insulation materials

- Sealed motor compartments with better water resistance

- Corrosion-resistant internal components

- Enhanced safety system redundancy

Consumer Education Importance

Despite technological improvements, prevention remains the most effective strategy. Even the most advanced hair dryers cannot guarantee safe operation after water exposure, making proper handling and storage practices essential.

| Technology Level | Protection Features | Water Resistance | Recovery Potential |

|---|---|---|---|

| Basic Consumer | Standard circuit breakers | Minimal | Very low |

| Mid-Range Models | GFCI protection | Moderate | Low |

| Professional Units | Multiple safety systems | Enhanced | Still limited |

| Premium Commercial | Comprehensive protection | Advanced | Marginal improvement |

For businesses serving professional markets, offering hair dryers with advanced water protection features provides competitive advantages while reducing customer losses from accidental water exposure incidents.

How to Prevent Hair Dryer Water Damage in Professional Settings?

Professional environments like salons, hotels, and spas require comprehensive strategies to prevent water damage while maintaining operational efficiency.

Professional settings should store hair dryers away from water sources, use GFCI outlets in all wet areas, train staff on proper handling procedures, regularly inspect devices for damage, and implement strict rules against using electrical devices near water.

Strategic Equipment Placement

Professional environments benefit from careful spatial planning:

- Maintain minimum safe distances from sinks, tubs, and water sources

- Install dedicated drying stations with proper drainage systems

- Use wall-mounted holders that keep devices elevated and dry

- Create clearly defined wet and dry zones in workspace design

Staff Training and Protocols

Comprehensive training programs should include:

- Proper handling techniques for high-moisture environments

- Emergency response procedures for water exposure incidents

- Regular equipment maintenance and inspection schedules

- Safety awareness training emphasizing water-electricity dangers

Electrical Infrastructure Requirements

Professional installations require upgraded electrical systems:

- GFCI protection on all circuits in wet areas

- Dedicated electrical circuits for high-power hair dryers

- Proper grounding systems throughout the facility

- Accessible emergency shutoff switches in critical locations

Equipment Selection and Maintenance

Choose commercial-grade equipment with:

- Enhanced water resistance ratings

- Professional-grade safety features and certifications

- Comprehensive warranty coverage and service support

- Documented reliability ratings for continuous commercial use

Insurance and Compliance Considerations

Professional operations must address:

- Equipment replacement policies for water damage incidents

- Liability coverage for electrical accidents and injuries

- Documentation requirements for safety compliance audits

- Regular professional safety inspections and maintenance records

| Prevention Strategy | Implementation Cost | Effectiveness Rating | Long-Term ROI |

|---|---|---|---|

| Strategic Placement | Low | High | Excellent |

| Staff Training Programs | Moderate | Very High | Excellent |

| Electrical Upgrades | High | Very High | Excellent |

| Premium Equipment | High | High | Very Good |

| Insurance Coverage | Moderate | High | Good |

Professional buyers should carefully evaluate these factors when selecting hair dryers for commercial applications. Our P1C high-speed hair dryer incorporates many professional-grade safety features while maintaining competitive pricing for bulk purchases.

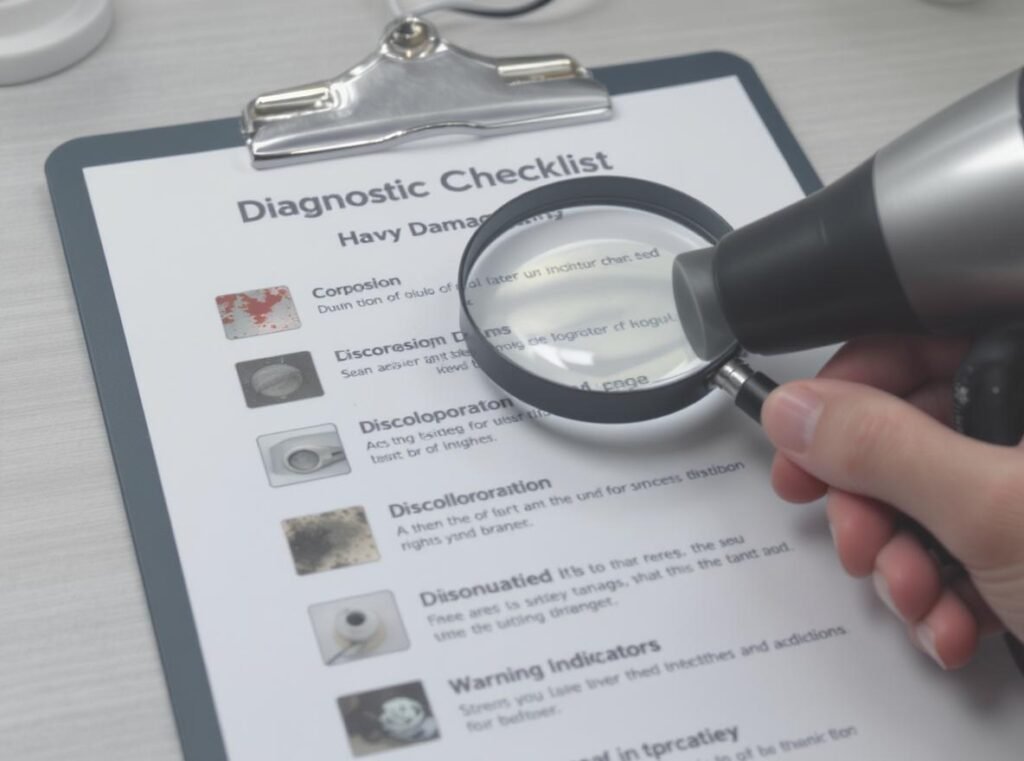

What Are the Signs Your Hair Dryer Has Water Damage?

Recognizing water damage symptoms early can prevent safety hazards and help determine when immediate replacement is necessary.

Water damage signs include unusual noises, reduced airflow, visible corrosion, burnt smells, sparking, unexpected shutdowns, and tripped circuit breakers. These symptoms indicate internal component failure and potential safety hazards requiring immediate device replacement.

Audible Warning Indicators

Water-damaged hair dryers produce distinctive sounds that signal internal problems:

- Grinding or scraping noises from corroded motor bearings

- Crackling sounds indicating electrical arcing and short circuits

- Unusual rattling from loose or damaged internal components

- Intermittent motor operation or stuttering performance patterns

Visual Damage Signs

Physical inspection may reveal:

- Visible corrosion or rust stains through air vents

- Discoloration of plastic housing materials

- Moisture condensation inside transparent components

- Mineral deposits or water stains on external surfaces

Performance Degradation Symptoms

Functional problems include:

- Significantly reduced airflow or heating effectiveness

- Inconsistent temperature control and heating patterns

- Overheating during normal operation cycles

- Frequent automatic shutoffs or thermal protection activation

Electrical System Warnings

Critical electrical symptoms include:

- Burning smells during operation

- Visible sparking from outlets, plugs, or device housing

- Circuit breaker trips or GFCI outlet activation when plugging in

- Shock sensations when touching the device or nearby surfaces

Safety-Critical Indicators

Immediate replacement required for:

- Smoke emission during use

- Unusual heat generation in housing materials

- Cord or plug damage, discoloration, or deformation

- Control switch malfunction, sticking, or erratic behavior

| Warning Sign | Immediate Action Required | Safety Risk Level | Replacement Urgency |

|---|---|---|---|

| Burning Smell | Stop use immediately | Critical | Replace immediately |

| Electrical Sparking | Unplug and dispose safely | Critical | Replace immediately |

| Smoke Emission | Emergency shutdown | Critical | Replace immediately |

| Grinding Sounds | Discontinue use | High | Replace within days |

| Reduced Performance | Monitor closely | Moderate | Consider replacement |

For retailers and distributors, understanding these warning signs helps you educate customers about equipment safety and provides natural opportunities to recommend quality replacements like our P1C high-speed hair dryer with advanced safety features.

Summary

Water exposure to hair dryers creates immediate safety hazards including electrical shock, electrocution, and fire risks that persist regardless of whether the device appears dry afterward. Professional repair typically costs $50-800 but is rarely recommended due to ongoing safety concerns and reduced reliability. Modern hair dryers include improved safety features like GFCI protection and immersion sensors, but complete water protection remains impossible.

Early recognition of water damage symptoms such as unusual sounds, burning smells, and performance degradation helps prevent safety incidents. Professional environments require comprehensive prevention strategies including strategic equipment placement, staff training, and electrical system upgrades to minimize water exposure risks.

For businesses in the hair care industry, partnering with manufacturers who prioritize safety and water resistance ensures access to quality products that protect customers and reduce liability. Explore our P1C high-speed hair dryer with advanced safety features, or browse our complete product collection for wholesale opportunities. Contact us today to discuss bulk pricing and professional-grade solutions for your business needs.