Hair dryer cord damage costs the professional styling industry millions annually through premature equipment replacement and safety hazards. Tight wrapping, heat exposure, and improper storage create stress points that destroy internal wiring and compromise electrical safety. Smart cord management techniques can extend your equipment’s lifespan by 40-60% while preventing costly emergency replacements.

The most effective way to prevent hair dryer cord damage is using the figure-eight coiling method for storage, never wrapping cords tightly around the dryer body, and investing in professional cord protection accessories like Tangle Stop covers. Regular inspection for exposed wires, scorch marks, or unusual stiffness helps identify problems early. Professional-grade equipment with swivel cords and reinforced connections significantly reduces maintenance requirements.

Ready to master professional cord care techniques that save thousands in replacement costs? These proven strategies will transform your equipment maintenance routine.

Table of Contents

ToggleWhat Are the Most Common Causes of Hair Dryer Cord Damage?

Understanding damage patterns helps wholesale customers protect their investment and train staff properly. Most failures stem from preventable daily habits that gradually destroy equipment.

The three primary causes of hair dryer cord damage are tight wrapping around the dryer body (creating stress points), repeated flexing at connection points, and heat exposure from improper storage. Tight wrapping creates stress from tighter angles, slowly wearing away protective covering and potentially damaging internal copper wires. Pet damage from chewing and environmental factors like humidity also accelerate deterioration.

Physical Stress Patterns

Tight wrapping around the dryer handle creates the most severe internal damage. When cords bend at sharp angles repeatedly, the copper wires inside break down while the outer sheathing appears intact.

Connection point stress occurs where the cord enters the dryer housing. This area experiences constant flexing during use and often fails first in high-usage environments.

Environmental factors compound these problems. Humid bathroom conditions allow moisture to penetrate damaged areas, while dust and debris accumulate in tangled cords.

- Heat exposure from storing cords against warm surfaces

- Pulling and yanking during unplugging instead of gripping the plug

- Stepping on cords or allowing them to catch on sharp edges

- Chemical exposure from cleaning products and styling chemicals

| Damage Type | Primary Cause | Failure Timeline | Prevention Method |

|---|---|---|---|

| Internal Wire Breaks | Tight wrapping | 6-12 months | Figure-eight coiling |

| Connection Point Failure | Repeated flexing | 12-18 months | Swivel cord technology |

| Sheathing Cracks | Heat/chemical exposure | 3-6 months | Cool, dry storage |

| Plug Deterioration | Improper unplugging | 8-15 months | Grip plug, not cord |

How Should You Properly Store Your Hair Dryer Using Professional Techniques?

Professional salons follow specific storage protocols that extend equipment life dramatically. The figure-eight coiling method prevents internal wire stress while maintaining cord flexibility.

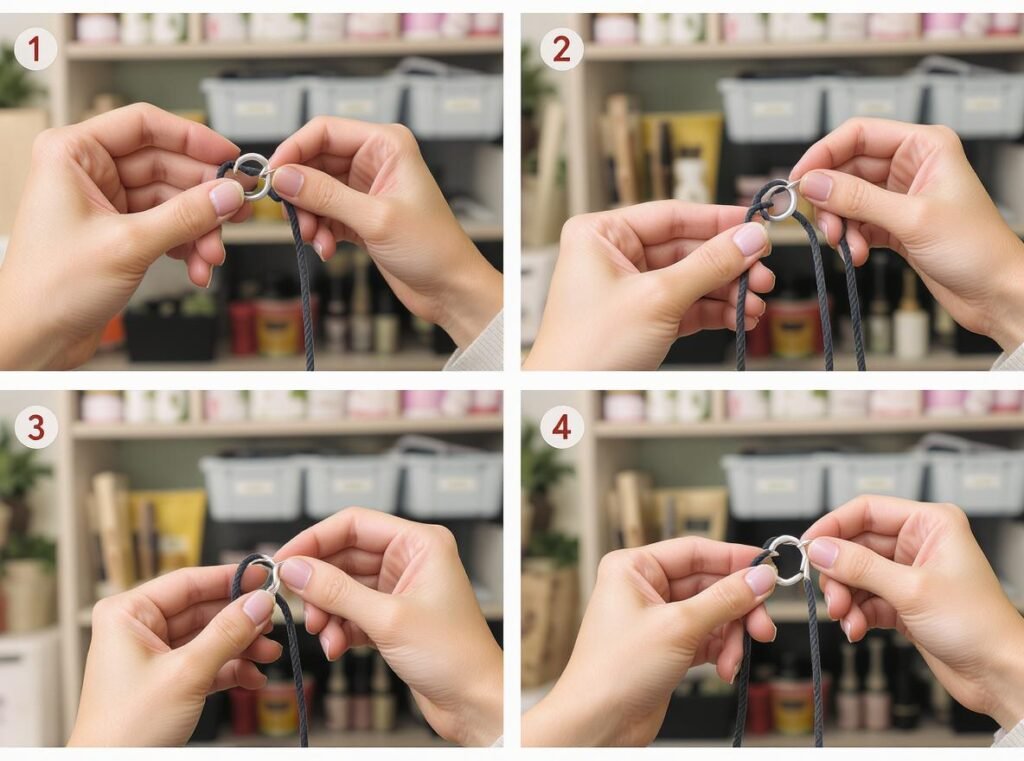

Store hair dryer cords using the over-under coiling technique, also known as the figure-eight method. This alternates loop directions to prevent internal wire stress: create the first loop normally, then twist your hand backward for the second loop, alternating throughout. Never wrap cords around the dryer body, and always use cool, dry storage areas away from heat sources.

The Professional Figure-Eight Method

Start with your dryer completely cooled and unplugged. Hold one end of the cord at eye level to begin the coiling process.

Create your first loop in the natural direction, making it approximately 12-18 inches in diameter. For the second loop, twist your hand backward as you coil, creating a reverse loop.

Continue alternating between normal and twisted loops until the entire cord is coiled. This technique prevents the cord from developing memory and reduces internal wire stress.

Secure the coiled cord with soft Velcro straps or fabric ties. Avoid rubber bands or twist ties that create pressure points and potential damage areas.

Creative Storage Solutions

Empty toilet paper rolls provide excellent cord management for smaller operations. Fold the cord compactly and slip it into the roll, allowing natural curves without tight bends.

Professional wall-mounted holders keep cords off counters and prevent tangling between multiple units. These systems work particularly well in busy salon environments.

- Designate specific storage areas away from moisture and heat sources

- Use separate containers for each styling tool to prevent cord interaction

- Maintain consistent storage temperatures to prevent material degradation

- Implement rotation systems for multiple dryers to distribute wear evenly

What Are the Most Effective Cord Protection Accessories for Professional Use?

Professional-grade cord protection accessories can extend equipment life by up to 50% while reducing maintenance costs significantly. These investments pay for themselves through reduced replacement frequency.

Tangle Stop Cord Covers are the gold standard for professional cord protection, featuring 9-foot abrasion-resistant polyethylene sleeves that prevent twisting and damage. BarberMate Cord Tangle Preventers offer 8-foot universal-fit sleeves for high-volume environments. These accessories remove existing cord memory while providing maximum protection against solvents, chemicals, and physical abrasion.

Premium Protection Systems

Spiral cord covers provide comprehensive protection against multiple damage types. These polyethylene sleeves resist most solvents and chemicals commonly found in professional environments.

Cord management systems organize multiple dryers effectively while preventing tangling between units. Wall-mounted systems work best for stationary setups, while mobile carts suit flexible styling environments.

Heat-resistant cord protectors focus on the critical connection area where temperature damage occurs most frequently. These reinforced sleeves maintain flexibility even under high-heat conditions.

Retractable cord systems eliminate storage problems entirely. Modern push-button retraction systems include internal guides that prevent tangling during operation.

| Protection Type | Coverage | Durability | Best Application |

|---|---|---|---|

| Spiral Covers | 9 feet | 3-5 years | High-volume salons |

| Cord Wraps | 6-8 feet | 2-3 years | Mobile styling |

| Heat Shields | 2-3 feet | 5+ years | Connection protection |

| Retractable Systems | Built-in | 7-10 years | Premium equipment |

How Do You Safely Untangle Hair Dryer Cords Without Causing Damage?

Professional untangling techniques prevent further damage while restoring cord functionality. The key is patience and systematic approach rather than forceful manipulation.

To safely untangle cords, lift the dryer to eye level and trace the original cord path before beginning. Work on all knots simultaneously rather than focusing on one area, and free loops systematically using one end as a guide. Never pull or yank tangled sections—use gentle manipulation and small tools like toothpicks for stubborn knots.

The Professional Barber Method

Professional barbers use “cord stripping” when managing multiple tangled tools. This systematic approach prevents time waste and reduces cord stress during untangling.

Start by unplugging all devices and allowing cords to fall naturally. Work in good lighting and avoid rushing the process, as patience prevents additional damage.

Pick up each tool individually and follow its cord path to the outlet. This methodical approach prevents creating new tangles while solving existing ones.

Use small tools like toothpicks or needles for stubborn knots, working from multiple angles with gentle pressure. Apply lubricant sparingly if knots resist gentle manipulation.

- Begin untangling from the loose end, working toward the tangle

- Work in short segments rather than attempting to solve everything at once

- Take breaks if frustration builds—rushing creates more problems

- Consider professional assessment if cords feel stiff or brittle during untangling

What Daily Habits Prevent Cord Damage in Professional Environments?

Consistent daily practices protect equipment investments more effectively than any repair technique. These habits become second nature and dramatically extend equipment life.

The most critical daily habit is proper unplugging technique—always grip the plug itself, never pull the cord. Allow dryers to cool completely before storage, maintain at least 6 inches distance from hair during use, and keep the dryer moving to prevent cord stress from prolonged positioning. Professional environments should rotate between multiple dryers to distribute wear evenly.

Essential Post-Use Procedures

Unplug correctly every single time by walking to the outlet and gripping the plug firmly. This single habit prevents more cord damage than any other practice.

Allow complete cooling before storage. Hot equipment can damage both the dryer and cord materials if stored while warm. Wait at least 10 minutes after intensive use.

Inspect cords regularly for early damage signs. Check for cracks, exposed wires, unusual stiffness, or areas where the cord feels different from normal flexibility.

Keep detailed maintenance logs for multiple units. Track usage patterns, repair history, and replacement schedules to optimize equipment rotation.

Professional Usage Techniques

Maintain proper distance during styling to prevent cord stress from extreme positioning. Professional stylists recommend staying at least 6 inches from hair during drying.

Keep cords off floors during use through proper draping techniques or cord management systems. Hanging cords last longer and won’t suffer damage from foot traffic.

- Handle equipment gently during styling, avoiding sudden movements

- Use designated storage areas consistently

- Train all staff on proper handling techniques

- Implement immediate replacement protocols for damaged cords

When Should You Replace Hair Dryer Cords Instead of Attempting Repairs?

Knowing replacement indicators prevents safety hazards while optimizing equipment budgets. Some damage patterns make repair impossible or economically unfeasible.

Replace hair dryer cords immediately if you notice exposed wires, scorch marks, areas of unusual stiffness or brittleness, burning smells during operation, or intermittent power requiring cord manipulation. Professional-grade dryers over $200 may justify professional repair, but most consumer models cost less to replace than repair when cords fail.

Critical Safety Indicators

Exposed copper wires create immediate fire and shock hazards. Even small areas of exposed wire can cause electrical faults, property damage, or personal injury.

Scorch marks or melted areas indicate heat damage that compromises cord integrity throughout the affected region. These areas continue weakening and may fail catastrophically.

Unusual stiffness or brittleness suggests internal damage invisible from outside inspection. These cords may work intermittently but are prone to sudden, complete failure.

GFCI tripping when the dryer is plugged in indicates electrical faults that require immediate replacement. Never attempt to bypass safety systems.

Cost-Benefit Analysis

Professional repair may be worthwhile for high-end dryers over $200, but replacement typically costs less for mid-range models. Consider the total cost of ownership including downtime and safety risks.

Equipment over 5 years old generally warrants replacement rather than repair, as additional components may fail soon after cord replacement.

If repair costs exceed 50% of replacement value, choose replacement to avoid throwing good money after bad.

How Do Professional Salons Maintain Hair Dryer Cords for Maximum Longevity?

Professional environments offer valuable lessons for wholesale customers managing multiple units. These systematic approaches maximize equipment investment while ensuring consistent performance.

Professional salons implement scheduled weekly inspection programs, use dedicated wall-mounted storage systems, and train all staff on proper handling techniques. They maintain backup equipment inventories and follow proactive replacement schedules every 2-3 years regardless of visible condition. Many salons choose dryers with 8-9 foot cords to reduce stress from stretching during use.

Systematic Maintenance Programs

Weekly inspections catch problems before they become safety hazards. Staff check each dryer’s cord for damage, clean connections, and verify proper operation.

Documentation systems track repair history and usage patterns. This data helps predict optimal replacement timing and identifies equipment with recurring problems.

Staff training ensures consistent handling practices across all employees. New staff learn proper techniques during orientation, not through trial and error.

Backup equipment prevents service disruption when primary units require maintenance. Professional salons typically maintain 20-30% backup capacity for busy periods.

Equipment Selection Criteria

Professional salons choose dryers with longer cord lengths (8-9 feet) to allow greater movement freedom. This reduces stress from stretching and pulling during styling.

Swivel cord technology prevents twisting damage during use. This feature particularly benefits high-volume environments where dryers see constant use.

Detachable cord systems allow easy replacement without servicing the entire unit. This feature significantly reduces maintenance costs and downtime.

- Prioritize equipment with reinforced connection points

- Choose models with heat-resistant cord materials

- Consider retractable cord systems for space-constrained environments

- Invest in professional-grade accessories for cord protection

What Are the Financial Benefits of Proper Hair Dryer Cord Maintenance?

Understanding the economic impact helps justify investment in proper maintenance tools, training, and procedures. The financial benefits extend beyond simple replacement cost savings.

Proper cord maintenance extends hair dryer life by 40-60% while preventing emergency replacements and service interruptions. Professional-grade dryers cost $100-500 each, making a $20-40 investment in cord protection highly cost-effective. For wholesale customers managing multiple units, these savings multiply significantly while reducing liability risks from electrical hazards.

Direct Cost Savings

Replacement costs escalate quickly in professional environments. High-quality dryers range from $100-400 each, while cord protection accessories cost $20-40 per unit.

Emergency replacement costs include rush shipping, premium pricing, and potential service disruption. Planned maintenance eliminates these premium costs.

Bulk purchasing power allows wholesale customers to negotiate better pricing on both equipment and accessories when ordering proactively rather than reactively.

Indirect Financial Benefits

Reduced liability exposure from electrical hazards prevents potentially catastrophic financial losses. Proper maintenance demonstrates due diligence in safety protocols.

Consistent equipment performance maintains professional image and customer satisfaction. Reliable equipment prevents service delays and maintains appointment schedules.

Staff efficiency improves when equipment works reliably without cord tangles or power interruptions. This productivity increase adds significant value in high-volume environments.

| Investment Category | Annual Cost | Potential Savings | ROI Timeline |

|---|---|---|---|

| Cord Protection Accessories | $20-40 | $200-500 | 2-3 months |

| Professional Storage Systems | $100-200 | $500-1500 | 4-6 months |

| Staff Training Programs | $200-300 | $1000-3000 | 6-12 months |

| Preventive Replacement | $300-500 | $1500-5000 | 12-18 months |

Which Modern Hair Dryer Features Best Prevent Cord Problems?

Advanced hair dryer technologies address common cord problems through improved design and materials. Understanding these features helps wholesale customers select equipment that requires less maintenance.

Modern professional hair dryers feature swivel cord technology that prevents twisting during use, reinforced strain relief at connection points, and heat-resistant materials that withstand high-temperature environments. Retractable cord systems eliminate storage problems entirely, while longer professional cords (8-9 feet) reduce stress from stretching. The Conason P1C incorporates these advanced features alongside professional-grade performance standards.

Advanced Cord Technologies

Swivel connections allow free cord rotation during styling, preventing the twisting damage that plagues fixed-cord designs. This technology particularly benefits high-volume professional environments.

Reinforced strain relief protects the critical connection area where most failures occur. These thick, flexible boots distribute stress over larger areas, preventing wire breakage.

Heat-resistant materials maintain flexibility even after extended exposure to high temperatures. Advanced thermoplastics and rubbers resist degradation from heat cycling.

Detachable cord systems revolutionize maintenance by allowing quick replacement without unit disassembly. Professional technicians can replace damaged cords in minutes rather than hours.

Professional-Grade Construction

Longer cord lengths (8-9 feet) reduce stress from stretching during professional use. This extra length allows greater styling freedom while protecting internal wires.

Brushless motor technology often includes improved electrical systems that reduce stress on power cords through more efficient operation and reduced heat generation.

Professional-grade shielding protects against electromagnetic interference while reducing heat buildup around connection points.

For wholesale customers seeking reliable, low-maintenance equipment, the Conason P1C high-speed hair dryer combines these advanced cord protection features with professional performance standards and competitive wholesale pricing.

How Do Retractable Cord Systems Compare to Traditional Storage Methods?

Retractable cord technology represents the ultimate solution for cord management problems, though it requires higher initial investment. Understanding the trade-offs helps inform equipment selection decisions.

Retractable cord hair dryers eliminate storage problems through push-button cord retraction systems with internal guides that prevent tangling. These systems typically last 7-10 years compared to 2-3 years for traditional cords, making them cost-effective despite higher upfront costs. The technology works best in stationary applications where the retraction mechanism won’t suffer from frequent movement.

Technology Advantages

Push-button operation eliminates manual coiling and reduces storage time significantly. Staff can prepare equipment for storage in seconds rather than minutes.

Internal cord guides prevent tangling during retraction, maintaining cord organization without user intervention. This automation reduces training requirements and ensures consistent results.

Space-saving design benefits cramped storage areas common in professional environments. Retractable systems typically require 50% less storage space than traditional coiling methods.

Reduced wear from handling means fewer touch points where damage can occur. The cord experiences less mechanical stress throughout its service life.

Implementation Considerations

Higher initial costs require careful cost-benefit analysis. Retractable systems typically cost 30-50% more than traditional designs but offer superior longevity.

Mechanical complexity introduces potential failure points in the retraction mechanism. However, quality systems from reputable manufacturers prove highly reliable.

Best applications include stationary styling stations where the retraction mechanism won’t suffer from frequent movement or transport stress.

- Evaluate total cost of ownership including maintenance savings

- Consider staff training requirements for new technology

- Assess compatibility with existing storage systems

- Plan for gradual implementation to minimize disruption

Summary

Preventing hair dryer cord damage requires systematic approaches combining proper storage techniques, professional-grade accessories, and consistent daily habits. The figure-eight coiling method, cord protection systems, and regular inspections dramatically extend equipment life while reducing safety risks. Professional maintenance programs save significantly more than they cost through reduced replacement frequency and improved reliability.

Ready to protect your hair dryer investment with professional-grade equipment? Explore our complete product collection featuring advanced cord protection technologies, or contact our wholesale team for volume pricing on bulk orders. We’ll help you select the optimal equipment mix for your specific operational requirements and budget constraints.