Are you wondering if you can use a hair dryer to bake polymer clay? This question comes up frequently among crafters looking for alternatives to traditional oven baking. Understanding the proper techniques and limitations is crucial for achieving successful results.

No, you cannot effectively bake polymer clay with a hair dryer. Polymer clay requires consistent temperatures of 265-275°F (130°C) for 15-30 minutes, while hair dryers rarely exceed 140°F (60°C) and deliver heat unevenly. However, hair dryers can be useful for conditioning certain clays and surface drying very thin pieces.

Let’s explore the complete guide to using hair dryers with polymer clay, including proper techniques, safety considerations, and when this method works best.

Table of Contents

ToggleCan You Actually Bake Polymer Clay with a Hair Dryer?

Many crafters assume that because hair dryers produce heat, they can substitute for oven baking. This misconception can lead to disappointing results and wasted materials.

Hair dryers cannot properly cure polymer clay because they don’t reach the required 265-275°F temperature and cannot maintain consistent heat throughout the piece. Most standard hair dryers max out at around 140°F (60°C), which is significantly lower than the curing temperature needed for proper polymer clay polymerization.

Temperature Requirements for Polymer Clay

Polymer clay requires specific temperature conditions for proper curing:

- Temperature range: 265-275°F (130°C)

- Duration: 15-30 minutes depending on thickness

- Heat distribution: Even throughout the entire piece

- Consistency: Stable temperature without fluctuations

The Science Behind Polymer Clay Curing

Polymer clay undergoes polymerization when heated properly. This chemical process requires:

- Sustained high temperature to activate the polymer chains

- Even heat distribution to prevent weak spots

- Adequate time for complete molecular bonding

- Consistent temperature to avoid thermal stress

Hair dryers fail to meet these scientific requirements, making them unsuitable as a primary baking method.

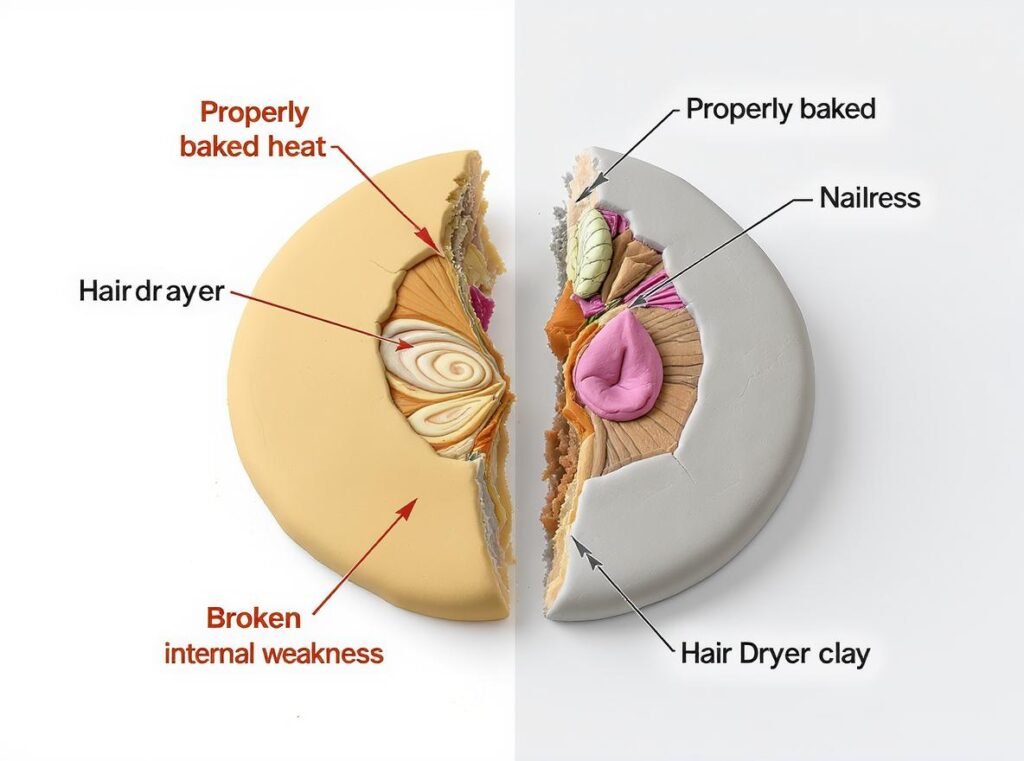

Surface Hardening vs. Proper Curing

Hair dryers may superficially harden the outer layer of very thin pieces, but the interior remains uncured and fragile. This creates a false sense of completion while leaving the clay structurally weak and prone to breakage.

How to Use a Hair Dryer for Polymer Clay Projects?

While hair dryers cannot bake polymer clay, they do have specific applications in polymer clay work when used correctly and with realistic expectations.

Hair dryers can be used for conditioning certain clays like Papa’s Clay, making them softer and easier to work with before sculpting. They can also provide surface drying for very thin pieces, though this should never be considered proper curing.

Conditioning Clay Applications

Some polymer clay brands benefit from hair dryer conditioning:

- Papa’s Clay Conditioning

- Use low heat setting to warm the clay

- Keep dryer moving to prevent overheating

- Work the clay while warming for better results

- General Clay Softening

- Warm stiff clay to make it more pliable

- Use for easier blending and manipulation

- Helpful for older clay that’s become hard

Surface Drying Technique

For very thin pieces, hair dryers can provide limited surface hardening:

- Only effective on pieces less than 1/8 inch thick

- Creates hard outer shell but soft interior

- Not suitable for functional or durable items

- Should be followed by proper oven baking

The Box Method for Better Heat Control

| Step | Action | Important Notes |

|---|---|---|

| 1 | Place clay in cardboard box | Use heat-resistant surface |

| 2 | Cut opening for dryer nozzle | Maintain 6-8 inch distance |

| 3 | Monitor temperature | Use infrared thermometer |

| 4 | Rotate piece frequently | Prevent uneven heating |

What Are the Limitations of Using Hair Dryers for Polymer Clay?

Understanding these limitations helps prevent frustration and project failures while setting realistic expectations for hair dryer applications.

The main limitations include insufficient heat (140°F max vs. 275°F required), uneven heating patterns, surface-only hardening, and time-consuming processes that still don’t achieve proper curing.

Temperature Limitations

Hair dryers face fundamental temperature constraints:

- Maximum output: 140°F (60°C)

- Required curing temperature: 265-275°F (130°C)

- Temperature gap: Over 125°F difference

- Inconsistent heat delivery across surfaces

Uneven Heat Distribution Problems

Hair dryers create several heating issues:

- Hot spots can cause warping or cracking

- Cool areas remain completely uncured

- Airflow patterns create temperature variations

- Moving the dryer disrupts heat consistency

Surface Hardening Deception

The most dangerous limitation is false curing:

- Outer layer may feel hard and finished

- Interior remains soft and uncured

- Leads to brittleness and unexpected breakage

- Creates weak structural integrity

Time and Efficiency Issues

Even prolonged hair dryer exposure fails to:

- Achieve proper molecular bonding

- Provide consistent results

- Match oven baking efficiency

- Deliver professional-quality outcomes

What Are the Best Alternatives to Hair Dryer Baking?

Professional crafters rely on proven methods that deliver consistent, reliable results for polymer clay projects.

The best alternatives include conventional ovens, toaster ovens, air fryers at correct temperatures, and heat guns for specialized applications. These methods provide the temperature control and even heating necessary for proper polymer clay curing.

Conventional Oven Method

The gold standard for polymer clay baking:

- Preheat to 275°F (135°C)

- Use oven thermometer for accuracy

- Bake 15-30 minutes per ¼ inch thickness

- Cover with aluminum foil tent to prevent scorching

Toaster Oven Solutions

Dedicated toaster ovens offer several advantages:

- Better temperature control than hair dryers

- Even heat distribution

- Dedicated craft use prevents food contamination

- Compact size fits craft spaces

- Energy efficient for small batches

Air Fryer Applications

Some crafters successfully use air fryers:

- Can reach proper curing temperatures

- Requires careful monitoring

- Good for small, thin pieces

- Need to adjust timing for air circulation

Alternative Methods Comparison

| Method | Temperature Control | Evenness | Curing Quality | Safety Rating |

|---|---|---|---|---|

| Hair Dryer | Poor | Poor | Incomplete | May cause warping |

| Conventional Oven | Excellent | Good | Complete | Safe with precautions |

| Toaster Oven | Excellent | Good | Complete | Safe with precautions |

| Air Fryer | Good | Good | Complete | Requires monitoring |

| Heat Gun | Moderate | Variable | Risk of burning | Use with caution |

How to Choose the Right Hair Dryer for Clay Work?

If you decide to use a hair dryer for conditioning clay or supplemental heating, selecting the right model can improve your results and safety.

Choose a hair dryer with multiple heat settings, high wattage for better airflow, and concentrator nozzles for directing heat precisely. However, remember that even the best hair dryer cannot properly cure polymer clay.

Key Features for Clay Conditioning

For conditioning applications, look for:

- Multiple heat and speed settings

- High wattage (1800+ watts) for consistent performance

- Concentrator nozzle attachments

- Cool shot button for quick cooling

- Lightweight design for extended use

Professional vs. Consumer Models

Professional hair dryers provide:

- Better temperature stability

- Longer lifespan under heavy use

- More precise heat controls

- Higher maximum temperatures (still insufficient for curing)

Safety Features to Prioritize

Essential safety features include:

- Overheating protection

- ALCI (Appliance Leakage Current Interrupter)

- Heat-resistant housing

- Automatic shut-off capabilities

- UL or ETL safety certification

Recommended Specifications

| Feature | Minimum Requirement | Ideal Specification |

|---|---|---|

| Wattage | 1600W | 1800W+ |

| Heat Settings | 2 | 3+ |

| Speed Settings | 2 | 3+ |

| Attachments | Concentrator | Multiple nozzles |

| Safety Features | Basic overheating | Full protection suite |

When Should You Use Traditional Oven Baking Instead?

Understanding when to choose oven baking over hair dryer heating ensures better results and prevents project failures.

Use traditional oven baking for all finished polymer clay projects, thick pieces, items requiring durability, and professional-quality results. Hair dryers should only be used for conditioning clay, never for final curing.

Projects Requiring Oven Baking

Certain projects absolutely need proper oven baking:

- Jewelry pieces requiring strength and durability

- Sculptural work with varying thickness

- Items intended for daily use or handling

- Pieces with embedded materials or armatures

- Complex assemblies with multiple components

Thickness and Complexity Considerations

Oven baking becomes essential for:

- Any piece over 1/8 inch thick

- Sculptures with solid sections

- Layered or built-up designs

- Hollow forms requiring structural integrity

- Mixed-media pieces combining different materials

Professional Quality Standards

For professional or commercial work, oven baking provides:

- Consistent quality across production batches

- Predictable and repeatable results

- Proper strength and flexibility characteristics

- Even color development throughout

- Reduced risk of cracking or brittleness

Long-term Durability Requirements

Properly oven-baked polymer clay:

- Maintains flexibility without becoming brittle

- Resists cracking under normal stress

- Develops full strength properties

- Achieves optimal translucency in transparent clays

- Provides reliable performance over time

What Safety Precautions Are Essential?

Safety should always be your top priority when working with heat and polymer clay, regardless of your chosen heating method.

Essential safety precautions include proper ventilation to avoid inhaling fumes, fire safety measures, electrical safety with hair dryers, and personal protective equipment. Never leave heating equipment unattended, and always have emergency procedures ready.

Ventilation Requirements

Both hair dryers and ovens require adequate ventilation:

- Open windows for fresh air circulation

- Use exhaust fans to remove heated air and any fumes

- Avoid working in confined or poorly ventilated spaces

- Consider respirator masks for extended work sessions

Fire Safety Measures

Polymer clay work poses fire risks at high temperatures:

- Keep fire extinguisher readily accessible

- Clear all flammable materials from work area

- Never exceed manufacturer’s recommended temperatures

- Monitor for signs of overheating, burning, or smoke

- Have emergency contact numbers readily available

Electrical Safety with Hair Dryers

Hair dryers pose specific electrical hazards:

- Use GFCI-protected outlets in work areas

- Inspect power cords for damage before each use

- Keep electrical connections away from work surfaces

- Never use damaged or malfunctioning equipment

- Unplug equipment when not in active use

Personal Protective Equipment

Protect yourself during polymer clay work:

- Heat-resistant gloves for handling warm clay or equipment

- Safety glasses when using power tools or heat guns

- Dust masks during sanding or finishing operations

- Closed-toe shoes to protect feet from dropped items

- Long sleeves when working with heat sources

Adult Supervision Requirements

When children are involved in polymer clay projects:

- Constant adult supervision is necessary

- Keep children away from heating equipment

- Teach proper safety procedures before starting

- Use only child-appropriate tools and techniques

- Have first aid supplies readily available

How Does Hair Dryer Heating Compare to Professional Methods?

Understanding the performance differences helps you choose the right method for your specific needs and desired quality level.

Hair dryers provide convenience and accessibility but completely lack the precision and reliability of professional methods. Ovens deliver superior temperature control, even heating, and consistent results that hair dryers cannot match for polymer clay curing.

Detailed Performance Comparison

| Aspect | Hair Dryer | Conventional Oven | Toaster Oven | Heat Gun |

|---|---|---|---|---|

| Temperature Control | Poor (140°F max) | Excellent (up to 500°F) | Excellent (precise) | Good (variable) |

| Even Heating | Poor (spotty) | Excellent (consistent) | Excellent (even) | Fair (focused) |

| Curing Quality | Incomplete | Complete | Complete | Risk of burning |

| Time Efficiency | Poor (ineffective) | Excellent (set timer) | Excellent (reliable) | Good (quick) |

| Safety | Fair (electrical risk) | Excellent (stable) | Excellent (contained) | Good (requires skill) |

| Cost | Low | Medium | Medium | Medium |

| Ease of Use | Good (familiar) | Excellent (foolproof) | Excellent (simple) | Fair (requires practice) |

Quality of Results

Professional oven baking produces:

- Consistently strong and durable pieces

- Even color development throughout

- Proper flexibility without brittleness

- Smooth, professional surface finish

- Predictable shrinkage and dimensional stability

Time and Efficiency Analysis

While hair dryers might seem faster initially, they often require:

- Multiple unsuccessful heating attempts

- Constant monitoring and repositioning

- Additional repair work on failed pieces

- Complete re-doing of projects when pieces fail

- Significantly more total time investment

Professional Recommendations

Polymer clay manufacturers and professional artists consistently recommend:

- Oven baking as the only reliable curing method

- Hair dryers exclusively for clay conditioning

- Heat guns only for specialized surface treatments

- Dedicated craft ovens for serious hobbyists

- Temperature monitoring equipment for all heating methods

What Equipment Do You Need for Success?

Having the right tools and equipment significantly impacts your polymer clay results, regardless of your chosen heating method.

Essential equipment includes accurate thermometers, heat-resistant surfaces, proper ventilation systems, and safety gear. For professional results, invest in quality tools designed specifically for polymer clay work rather than relying on improvised solutions.

Essential Equipment for Oven Baking

For proper polymer clay curing:

- Dedicated craft oven or reliable toaster oven

- Accurate oven thermometer (not just oven dial)

- Ceramic tiles or glass baking sheets

- Aluminum foil for tenting

- Heat-resistant gloves for handling

- Timer for accurate baking duration

Hair Dryer Conditioning Kit

If using hair dryers for clay conditioning:

- Variable temperature hair dryer

- Infrared thermometer for surface monitoring

- Heat-resistant work surface

- Ventilation fan for air circulation

- Timer for conditioning sessions

Professional Upgrade Options

Serious crafters should consider:

- Convection ovens for even heat distribution

- Digital temperature controllers for precision

- Professional-grade heat guns for specialized work

- High-quality ventilation systems

- Dedicated polymer clay work surfaces

Safety Equipment Checklist

Essential safety gear includes:

- Fire extinguisher rated for electrical fires

- First aid kit with burn treatment supplies

- GFCI outlets or portable GFCI adapters

- Adequate lighting for work area

- Emergency contact information posted

Tool Maintenance Requirements

Proper maintenance ensures safety and performance:

- Regular cleaning of oven interiors

- Calibration of temperature measuring devices

- Inspection of electrical cords and connections

- Replacement of worn safety equipment

- Documentation of maintenance schedules

For professional polymer clay work and conditioning applications, we recommend investing in quality equipment. If you’re looking for professional-grade hair dryers for your craft projects, consider browsing our product collection for high-performance options designed for consistent results.

Summary

Hair dryers cannot effectively bake polymer clay due to insufficient temperature (140°F vs. required 275°F) and uneven heating patterns. While useful for conditioning certain clays, proper oven baking remains the only reliable method for curing polymer clay projects. Always prioritize safety and use appropriate equipment for professional results.

Ready to upgrade your polymer clay toolkit? Explore our high-performance hair dryers designed for consistent heating applications, or check out our featured P1C high-speed hair dryer for professional-quality performance. Contact us today to discuss wholesale opportunities for your business!