Tired of dealing with flyaway hair and static electricity every time you blow-dry? You’re not alone. Static buildup turns what should be a simple styling routine into a frustrating battle against unruly, frizzy hair that seems to have a mind of its own.

Static-free technology in hair dryers is achieved through negative ion generation systems that produce negatively charged particles to neutralize positive charges in hair. Combined with ceramic and tourmaline materials for even heat distribution, these technologies eliminate static buildup while reducing drying time and creating smoother, more manageable hair.

But there’s so much more to understand about how this game-changing technology actually works and why it matters for your hair care routine.

Table of Contents

ToggleWhat Causes Static Electricity in Hair?

Understanding static buildup is crucial for anyone dealing with unmanageable hair after blow-drying.

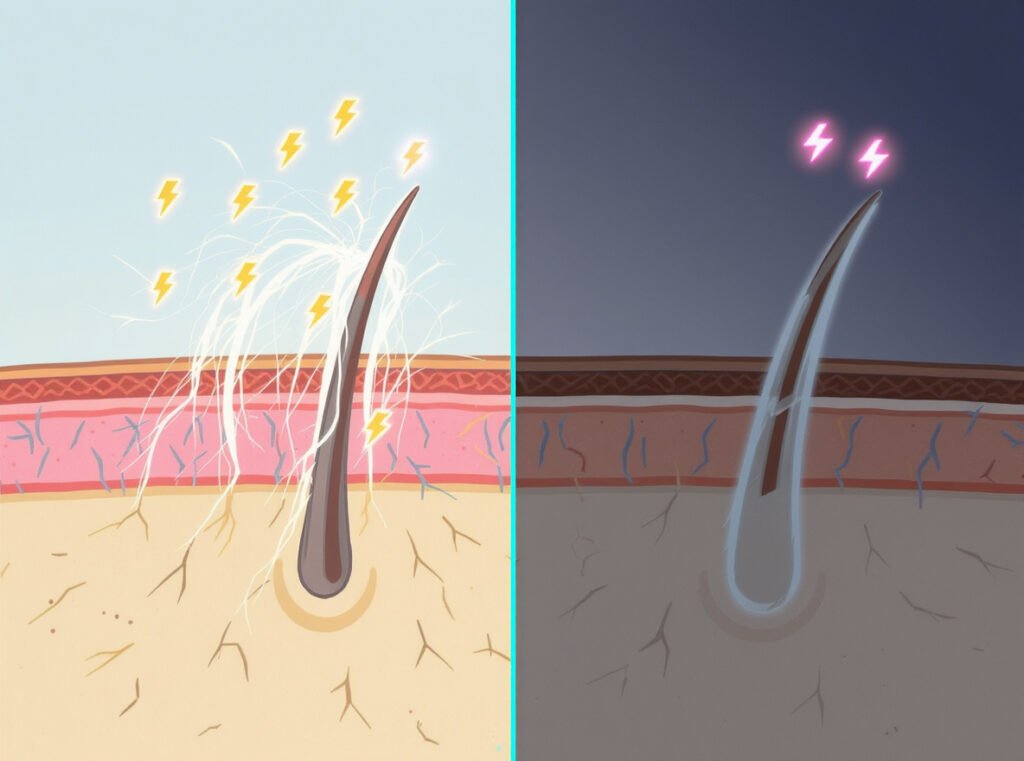

Static electricity in hair occurs through electron transfer from friction when hair rubs against brushes, towels, or clothing. This leaves hair strands with electrical charges that repel each other like magnets with the same charge, creating the characteristic flyaway appearance.

The science behind static formation involves several key factors. When you towel-dry your hair or brush it vigorously, electrons transfer between materials. This electron transfer leaves your hair with an electrical imbalance – typically a positive charge.

Since like charges repel each other, your positively charged hair strands push away from one another. This creates that frustrating volume you don’t want – the kind that makes your hair look messy rather than styled.

Environmental conditions significantly impact static formation. Low humidity conditions below 30% create perfect conditions for static buildup because dry air acts as a poor electrical conductor. Water vapor in humid air acts as a “bridge” for electrons to escape naturally, reducing static accumulation.

| Hair Type | Static Susceptibility | Primary Causes |

|---|---|---|

| Fine Hair | High | Light weight, low resistance to electrical forces |

| Damaged Hair | Very High | Lacks natural moisture to dispel charges |

| Coarse Hair | Medium | Better natural moisture retention |

How Do Hair Dryers Generate Negative Ions?

Modern ionic hair dryers use sophisticated technology to produce the negative ions that combat static electricity.

Hair dryers generate negative ions through two primary methods: active electromagnetic generators with high-voltage components that create corona discharge effects, and passive generation using heated materials like tourmaline that naturally emit ions when heated.

Active Ion Generation Systems

These systems use built-in electromagnetic generators with high-voltage components. The process creates corona discharge effects where voltage causes ions to leave metal prongs and attach to air molecules, producing negatively charged particles.

Key components include:

- High-voltage electrodes that create electrical fields

- Metal prongs or plates that emit ions into the airstream

- Fan systems that distribute ions evenly throughout the airflow

- Voltage regulation systems that control safe ion production levels

Passive Ion Generation Technology

This approach utilizes heated materials like tourmaline, ceramic, or titanium that naturally emit negative ions when heated. Tourmaline crystals demonstrate piezoelectric effects – when crushed into powder and integrated into dryer components, they generate consistent negative ions through heat activation.

Ion Output Variations

Professional-grade ionic dryers can produce 200 million negative ions per second, while basic ionic systems generate significantly fewer ions. Higher ion concentration directly correlates with more effective static reduction, making output levels a crucial specification for wholesale buyers.

How Do Negative Ions Neutralize Static Electricity?

The interaction between negative ions and your hair involves precise physics that directly solves the static problem.

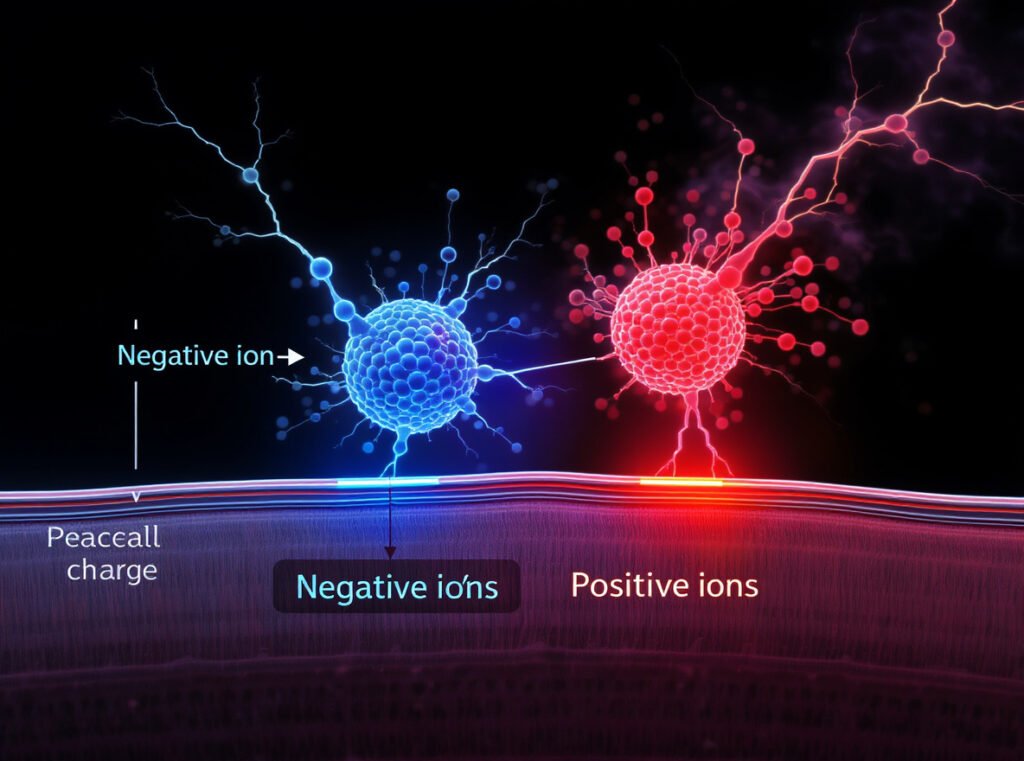

Negative ions neutralize static through charge balancing. Water molecules in wet hair carry positive charges, creating electrical imbalance. When negative ions from the dryer encounter these positively charged water molecules, they neutralize each other, eliminating the electrical charge responsible for static.

This neutralization process creates immediate benefits beyond static reduction:

Cuticle Sealing: Negative ions help flatten and seal hair cuticles, creating smoother surfaces that reflect light more evenly. This results in enhanced shine and reduced frizz.

Moisture Retention: Sealed cuticles lock in natural moisture and oils, preventing the dryness that exacerbates static formation. This maintains optimal hair health during the drying process.

Faster Water Molecule Breakdown: Negative ions break down large water droplets into smaller particles that are one-thousandth the diameter of vapor particles. These micro-particles evaporate more quickly, reducing overall drying time while simultaneously addressing static issues.

The beauty of this system lies in its dual action – eliminating static while improving overall hair health and appearance through proper moisture management and cuticle care.

What Role Do Ceramic and Tourmaline Materials Play?

While ionic technology handles electrical neutralization, ceramic and tourmaline materials provide crucial support for comprehensive static reduction.

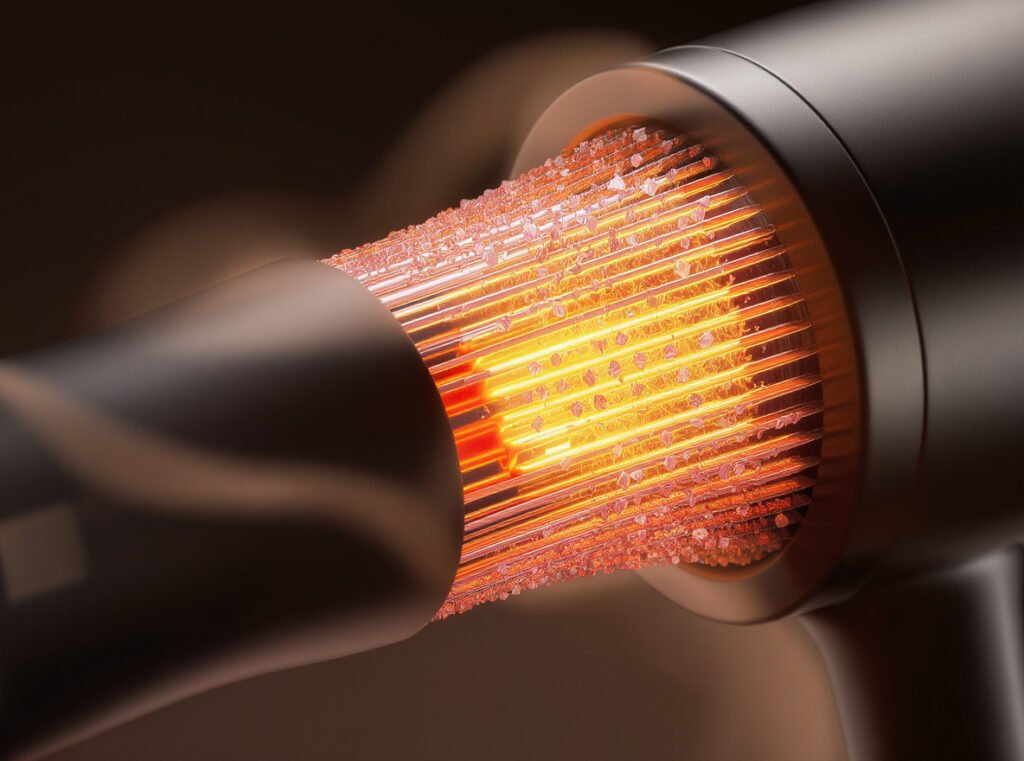

Ceramic technology delivers consistent heat distribution that prevents hot spots which can damage hair and create conditions for static buildup. Tourmaline offers superior negative ion production through natural piezoelectric properties when heated, often reducing drying time by up to 40% compared to conventional models.

Ceramic Technology Benefits

Ceramic-coated heating elements provide several advantages over traditional metal coils:

- Even Temperature Distribution: Prevents hot spots that damage hair and increase static formation

- Infrared Heat Emission: Gentle infrared heat penetrates hair shafts more effectively, allowing lower temperature settings

- Consistent Performance: Maintains stable heat output across all settings for predictable results

Tourmaline Integration Advantages

This semi-precious mineral offers unique properties when integrated into hair dryer construction:

- Natural Ion Generation: Crushed tourmaline crystals generate consistent negative ions when heated

- Dual-Action Systems: Works alongside electronic ion generators for maximum effectiveness

- Enhanced Infrared Heat: Provides both ion production and improved heat penetration

| Technology Type | Primary Benefit | Secondary Benefit |

|---|---|---|

| Ceramic | Even heat distribution | Reduced heat damage |

| Tourmaline | Natural ion generation | Faster drying times |

| Combined Systems | Maximum static reduction | Professional-grade results |

Hybrid Ceramic-Tourmaline Systems

Advanced dryers combine these technologies to maximize benefits. These systems deliver both optimal heat distribution and high negative ion output, creating ideal conditions for static-free drying across all hair types.

What Are the Different Types of Static-Free Technologies?

Modern hair dryers incorporate various technological approaches to achieve static-free results, each with distinct advantages for different applications.

The main static-free technologies include ionic systems (electronic negative ion generation), ceramic heating elements (even heat distribution), tourmaline integration (natural ion production), titanium technology (lightweight rapid heating), and hybrid systems that combine multiple approaches for comprehensive static control.

Pure Ionic Technology

Electronic ion generators represent the most common approach, focusing primarily on negative ion production through electrical means. These systems work independently of heat settings and provide consistent ion output with adjustable levels in premium models.

Ceramic Technology Systems

These focus on heat management rather than direct ion generation, preventing moisture loss and cuticle damage that contribute to static formation through consistent, gentle heat distribution.

Tourmaline-Enhanced Models

Natural negative ion generation combined with enhanced infrared heat makes tourmaline particularly effective for static reduction. The piezoelectric properties create consistent ion output when heated.

Titanium Technology Applications

While primarily valued for lightweight construction and rapid heating capabilities, properly engineered titanium components can contribute to negative ion production alongside weight reduction benefits.

Professional Hybrid Systems

Advanced dryers integrate multiple technologies for comprehensive static control:

- Ionic generators for immediate charge neutralization

- Ceramic heating elements for consistent heat distribution

- Tourmaline components for natural ion supplementation

- Titanium construction for professional durability and performance

These sophisticated systems maximize static reduction effectiveness across different hair types and styling requirements.

How Effective Is Static-Free Technology for Different Hair Types?

Static-free technology performance varies significantly based on hair characteristics, requiring targeted approaches for optimal results.

Fine hair benefits most dramatically from ionic technology with lower wattage (1400-1600W) and adjustable heat settings to prevent over-drying. Thick and coarse hair requires higher wattage ionic dryers (1800W+) with tourmaline integration, while curly hair needs ionic systems with diffuser attachments to preserve curl patterns.

Fine Hair Optimization

Ionic technology particularly benefits fine hair by addressing weight-related static issues. Key considerations include:

- Lower wattage prevents over-drying that exacerbates static

- Multiple heat settings allow precise temperature control

- Shorter exposure times minimize heat damage

- Dramatic static reduction with minimal effort required

Thick and Coarse Hair Requirements

Dense hair textures need more intensive treatment for effective static control:

- Higher wattage (1800W+) provides necessary power for penetration

- Tourmaline technology proves especially effective for frizz-prone thick hair

- Longer drying sessions may be necessary for complete treatment

- Combined technologies show superior results over single-system approaches

Curly Hair Considerations

Natural curl patterns require specialized approaches to maintain texture while reducing static:

- Ionic dryers with diffuser attachments preserve curl formation

- Negative ions seal cuticles without disturbing natural patterns

- Lower heat settings prevent disruption of curl structure

- Even ion distribution maintains consistent results across all curl sections

Chemically Treated Hair Needs

Color-treated, permed, or chemically straightened hair often responds exceptionally well to static-free technology:

| Treatment Type | Recommended Technology | Key Benefits |

|---|---|---|

| Color-treated | Ceramic + Ionic | Gentle heat, charge neutralization |

| Chemically straightened | Tourmaline + Ceramic | Natural ions, even heat |

| Permed hair | Low-heat ionic | Minimal disruption, static control |

What Should Wholesalers Look for in Static-Free Hair Dryers?

For distributors and retailers, understanding technical specifications ensures you stock products that deliver genuine static-free benefits to end customers.

Wholesalers should prioritize hair dryers with measurable ion generation rates (minimum 3 million negative ions per cubic centimeter), genuine ceramic heating elements, professional wattage levels (1800-2400W for salon use), and proper safety certifications including UL standards for electrical safety.

Essential Technical Specifications

| Specification | Professional Grade | Consumer Grade | Critical Notes |

|---|---|---|---|

| Power Output | 1800-2400 watts | 1400-1600 watts | Higher wattage for salon durability |

| Ion Generation | 200+ million/second | 3+ million/cm³ | Measurable output rates required |

| Motor Type | AC motors | DC motors | AC for professional durability |

| Heat Settings | 3-4 levels + cool shot | 2-3 levels | Multiple options for hair types |

Material Quality Standards

Verify authentic component integration rather than surface treatments:

- True Ceramic Elements: Look for genuine ceramic heating elements rather than ceramic coatings that may wear off

- Tourmaline Integration: Confirm actual tourmaline crystal integration versus surface treatments

- Ion Generation Verification: Request measurable negative ion output specifications

- Build Quality Assessment: Professional models should withstand continuous daily use

Performance Certifications Required

- UL Certification: Essential for electrical safety and thermal protection

- Ion Output Documentation: Verified negative ion generation rates with testing data

- Durability Standards: Professional models rated for extended daily salon use

- Safety Compliance: Complete electrical and thermal safety testing documentation

Customer Education Points

Help retail partners understand realistic expectations:

- Static reduction versus complete elimination (set appropriate expectations)

- Proper technique requirements for maximum effectiveness

- Maintenance needs for optimal long-term performance

- Compatibility considerations with different hair care products

The Conason P1C high-speed hair dryer exemplifies these quality standards with advanced negative ionic technology producing consistent ion output and ceramic components designed for professional-grade static reduction.

How to Maximize Static-Free Results?

Even the most advanced static-free technology requires proper application techniques to deliver optimal performance.

Maximum static-free results require using ionic hair dryers on slightly damp (not soaking) hair, maintaining 6-8 inches distance from the scalp, directing airflow from roots to tips following natural cuticle direction, and finishing with cool shot to seal cuticles and lock in anti-static effects.

Pre-Drying Preparation Techniques

Start with proper hair preparation to optimize ionic effectiveness:

- Gently towel-dry to remove excess moisture without aggressive rubbing

- Apply heat protectant products evenly to enhance ion interaction

- Detangle hair completely before beginning to ensure even ion exposure

- Section hair for more thorough negative ion contact with all strands

Optimal Application Methods

Root-to-Tip Technique: Direct airflow from roots toward ends to smooth cuticles and enhance shine while maximizing ion effectiveness.

Section Control: Work in small sections to ensure thorough ion exposure across all hair strands, preventing missed areas that could retain static charges.

Distance Management: Maintain proper 6-8 inch distance to allow adequate ion distribution without excessive heat concentration.

Cool Shot Finishing: Always finish with cool air to seal cuticles and lock in anti-static effects for lasting results.

Complementary Product Integration

Enhance ionic effectiveness with proper product selection:

- Heat Protectants: Applied before drying to improve ion interaction with hair

- Hydrating Formulas: Use moisture-rich shampoos and conditioners to maintain optimal hair moisture levels

- Anti-Static Accessories: Combine ionic drying with natural-bristle brushes to minimize friction-based static

- Leave-in Treatments: Light conditioning products can supplement the moisture-sealing effects of negative ions

Environmental Optimization Factors

- Humidity Control: Maintain room humidity above 30% to support natural static dissipation

- Equipment Maintenance: Regular filter cleaning ensures optimal airflow and consistent ion generation

- Temperature Moderation: Use the lowest effective heat settings to prevent moisture loss that contributes to static formation

Summary

Static-free technology in hair dryers represents a significant scientific advancement achieved through sophisticated negative ion generation systems, advanced ceramic heating materials, and specialized tourmaline integration. These technologies work together to neutralize the positive electrical charges responsible for static buildup while improving overall hair health through better moisture retention and cuticle care.

For wholesalers and retailers, investing in quality ionic hair dryers with genuine ceramic and tourmaline components means offering customers proven solutions to static problems while building reputation for effective, professional-grade products.

Ready to explore premium static-free hair dryers for your inventory? Browse our complete product collection at https://conason.com/product/ or contact us directly to discuss wholesale opportunities. The Conason P1C, featuring advanced negative ionic technology and professional-grade ceramic components, delivers the measurable static reduction your customers demand.