Hair dryer manufacturers face increasing pressure to reduce development costs, accelerate time-to-market, and create innovative designs that stand out in competitive markets. Traditional manufacturing methods create bottlenecks with expensive tooling requirements and lengthy prototyping cycles. 3D printing technology is revolutionizing this landscape.

3D printing is transforming hair dryer manufacturing by enabling rapid prototyping cycles from weeks to hours, reducing development costs by 60-80%, and allowing complex internal geometries impossible with traditional methods. Leading manufacturers like Philips now offer 3D-printed replacement parts, while companies can create custom components, optimize airflow channels, and accelerate innovation cycles.

Discover how this additive manufacturing revolution is reshaping product development and opening new opportunities for wholesale suppliers.

Table of Contents

ToggleWhat Role Does 3D Printing Play in Hair Dryer Prototyping?

Prototyping represents the most critical bottleneck in hair dryer development, where traditional methods require weeks and expensive tooling investments. Modern manufacturers need rapid iteration capabilities to stay competitive in fast-moving markets.

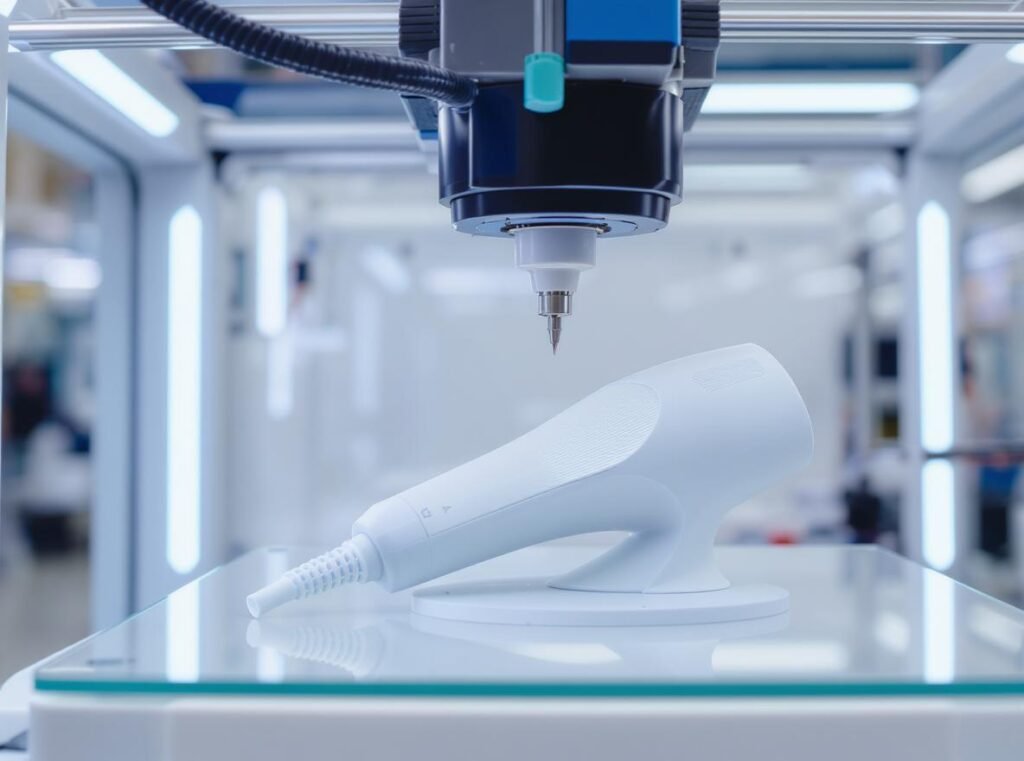

3D printing revolutionizes hair dryer prototyping by compressing development timelines from weeks to hours, enabling parallel component testing, and allowing functional prototypes with moving parts. Manufacturers can now test airflow dynamics, ergonomics, and thermal performance without expensive mold investments.

The Dyson Supersonic development required 600 prototypes over four years, demonstrating the critical importance of rapid iteration in creating breakthrough products. With 3D printing, this process would accelerate dramatically, allowing more design variations and faster optimization cycles.

Companies like Huux, a leading OEM/ODM personal care manufacturer, now leverage 3D printing for accelerated prototyping that enables parallel development of heating element housings, motor brackets, and airflow channels simultaneously rather than sequentially.

Key prototyping advantages include:

- Functional testing of airflow patterns and thermal distribution

- Ergonomic validation with actual user testing

- Material property evaluation under real operating conditions

- Integration testing of electronic components and mechanical systems

| Traditional Prototyping | 3D Printing Approach | Improvement Factor |

|---|---|---|

| 2-4 weeks timeline | 4-24 hours | 10-40x faster |

| $5,000-15,000 per iteration | $50-200 per prototype | 25-300x cost reduction |

| Single design path | Multiple parallel concepts | Unlimited variations |

The technology enables creation of complex internal structures like hollow airflow channels, integrated cooling systems, and lightweight honeycomb designs that optimize performance while reducing material usage. These geometries would be impossible or prohibitively expensive with traditional manufacturing methods.

How Does 3D Printing Reduce Hair Dryer Development Costs?

Development costs significantly impact product profitability and market positioning, especially for wholesale suppliers serving diverse global markets. Traditional manufacturing demands substantial upfront investments that create financial barriers to innovation.

3D printing reduces hair dryer development costs by 60-80% through elimination of expensive tooling, material waste reduction, and compressed development cycles. Manufacturers eliminate mold investments ranging from $10,000-50,000 per component while achieving material efficiency of 95% compared to 30-40% in traditional subtractive manufacturing.

Cost reduction occurs across multiple development phases. Initial concept validation requires minimal investment compared to traditional injection molding approaches. The technology enables cost-effective exploration of radical design concepts without financial constraints that typically limit innovation.

Material efficiency delivers substantial savings:

- Zero waste additive process versus 60-70% waste in machining

- On-demand production eliminates inventory carrying costs

- Reduced shipping expenses for prototype components

- Lower labor requirements for setup and changeover operations

Small-batch production capabilities allow manufacturers to test market demand before large-scale commitments. This approach minimizes inventory risk while enabling rapid response to customer feedback and market trends.

The elimination of tooling maintenance costs provides ongoing savings. Traditional molds require regular maintenance, repair, and eventual replacement, while 3D printing maintains consistent quality without degradation over time.

What Custom Components Can Be 3D Printed for Hair Dryers?

Component customization drives product differentiation and enables specialized solutions for diverse market segments. Traditional manufacturing constraints limit design possibilities due to tooling economics and geometric restrictions.

3D printing enables production of custom concentrator nozzles, diffuser attachments, ergonomic grips, internal airflow channels, and specialized mounting brackets. Heat-resistant materials including ABS, polycarbonate, PEEK, and high-temperature resins withstand operating temperatures up to 250°C while providing design freedom impossible with conventional methods.

The Reddit 3D printing community demonstrates significant interest in custom nozzle creation, with users sharing designs for specialized attachments difficult to purchase commercially. These custom solutions enable precise airflow control for specific styling needs and hair types.

Practical custom components include:

- Concentrator nozzles with optimized opening geometries for precision styling

- Diffuser attachments with customized hole patterns for different hair textures

- Ergonomic grips designed for specific hand sizes and usage patterns

- Lightweight internal structures using honeycomb or lattice designs

- Custom mounting systems for professional salon applications

| Component Type | Traditional Limitations | 3D Printing Capability |

|---|---|---|

| Concentrator Nozzles | Standard sizes only | Unlimited custom geometries |

| Diffusers | Universal hole patterns | Hair-type specific optimization |

| Internal Channels | Simple straight passages | Complex curved airflow paths |

| Ergonomic Features | One-size-fits-all | Personalized comfort design |

Philips has pioneered this approach through their “Fixables” program with Prusa Research, offering downloadable designs for replacement parts including trimmer combs and expanding to hair dryer components. This initiative demonstrates confidence in 3D printing quality and reliability for consumer applications.

Replacement part production becomes economically viable for low-volume requirements, enabling manufacturers to offer long-term support for discontinued models without maintaining expensive tooling inventory.

How Does 3D Printing Impact Hair Dryer Design Innovation?

Design innovation distinguishes market leaders from followers, driving premium positioning and customer loyalty. Traditional manufacturing constraints have historically limited innovation potential in hair dryer development.

3D printing liberates hair dryer design innovation by enabling biomimetic structures, integrated multi-functionality, complex internal geometries, and rapid testing of unconventional concepts. Designers can now create leaf-inspired airflow channels, honeycomb weight reduction structures, and organic ergonomic shapes based on hand anatomy studies.

Revolutionary design possibilities emerge through additive manufacturing freedom. Internal cooling channels can follow optimal heat dissipation paths rather than being limited to straight-line drilling capabilities. Airflow optimization becomes possible through computational fluid dynamics integration with 3D printing production.

Innovation opportunities span multiple dimensions:

- Biomimetic airflow systems inspired by natural ventilation patterns

- Integrated electronics housing with optimized electromagnetic shielding

- Organic ergonomic shapes that conform to natural hand positions

- Multi-material construction combining rigid and flexible elements

The technology enables integration of multiple functions into single components. Traditional hair dryers require separate parts for structural support, airflow direction, heat management, and aesthetic appeal, while 3D printing combines these functions seamlessly.

Advanced materials including conductive filaments enable embedded electronics integration, creating truly smart devices with integrated sensors, control systems, and user interface elements printed directly into the component structure.

Rapid iteration cycles accelerate innovation timelines from months to days, encouraging experimental approaches that lead to breakthrough innovations. This speed advantage allows manufacturers to explore multiple radical concepts simultaneously rather than following conservative single-path development strategies.

What Are the Quality Control Benefits of 3D Printing in Manufacturing?

Quality control represents a critical success factor in hair dryer manufacturing, affecting safety compliance, performance consistency, and brand reputation. Traditional manufacturing quality issues often surface late in development when corrections become expensive.

3D printing enhances quality control through precise dimensional accuracy (±0.05-0.1mm versus ±0.1-0.5mm traditional), consistent material properties, real-time monitoring capabilities, and elimination of human assembly errors. Digital traceability tracks every component parameter while automated layer-by-layer inspection ensures quality maintenance throughout production.

Quality advantages begin with digital design files that ensure perfect reproduction without interpretation errors common in traditional manufacturing. Each component matches exact specifications without variation between production runs, eliminating quality drift associated with tooling wear.

Advanced quality control features include:

- Real-time monitoring with automatic defect detection

- Layer-by-layer quality verification during production

- Digital documentation for regulatory compliance

- Consistent material properties independent of operator variables

Modern 3D printing systems incorporate machine learning algorithms that predict potential quality issues before they occur, enabling proactive adjustments that maintain consistent output quality.

| Quality Metric | Traditional Manufacturing | 3D Printing |

|---|---|---|

| Dimensional Tolerance | ±0.1-0.5mm | ±0.05-0.1mm |

| Repeatability | Variable with tooling wear | Consistently excellent |

| Defect Detection | Post-production inspection | Real-time monitoring |

| Documentation | Manual measurement records | Automatic digital tracking |

Material property consistency eliminates variations caused by temperature and pressure fluctuations in injection molding. 3D printing maintains stable processing conditions throughout production, ensuring reliable performance characteristics.

Post-processing quality control becomes more straightforward with built-in surface finish requirements and geometric accuracy. This integration reduces secondary operations while improving overall component quality.

How Does 3D Printing Affect Hair Dryer Production Speed?

Production speed directly impacts market responsiveness and competitive positioning, especially for wholesale suppliers serving global markets with varying seasonal demands. Traditional manufacturing bottlenecks limit flexibility and increase inventory requirements.

3D printing accelerates hair dryer production by eliminating tooling requirements, enabling parallel processing, and supporting on-demand manufacturing. Lead times reduce from 6-8 weeks to 1-3 days, while simultaneous production of multiple component types maximizes equipment utilization and reduces per-part production time.

Speed improvements occur across the entire production cycle. Companies can move directly from design validation to production without tooling preparation, changeover procedures, or minimum order quantity constraints that characterize traditional manufacturing.

Production acceleration benefits include:

- Instant production start without setup requirements

- Parallel processing of multiple components on single platforms

- Rapid design changes without retooling delays

- Flexible capacity allocation based on demand patterns

On-demand production eliminates inventory holding times and reduces storage requirements. Manufacturers can produce components as needed rather than maintaining large stockpiles that tie up capital and storage space.

The technology enables rapid response to seasonal fluctuations without maintaining excess production capacity. Equipment can shift between different product lines instantly, maximizing utilization while minimizing changeover costs.

Automated print farms with multiple systems enable 24/7 production without human intervention, dramatically increasing throughput while reducing labor costs and production complexity.

What Materials Are Used in 3D Printed Hair Dryer Components?

Material selection determines component performance, safety compliance, and durability characteristics. Hair dryer applications demand materials that withstand thermal cycling, mechanical stress, and electrical requirements while maintaining dimensional stability.

Advanced thermoplastics including ABS, PETG, polycarbonate (PC), PEEK, and specialized high-temperature resins enable production of durable hair dryer components. These materials offer heat resistance up to 250°C, excellent mechanical strength, electrical insulation properties, and chemical resistance suitable for consumer appliance applications.

Material capabilities continue expanding with technological advancement. Modern 3D printing materials match or exceed traditional injection molding materials in critical performance characteristics including thermal stability, impact resistance, and long-term durability.

High-performance material options include:

- ABS for structural housing with heat resistance to 100°C

- Polycarbonate (PC) for high-impact components to 150°C

- PEEK for extreme temperature applications to 250°C

- PETG for chemical resistance and optical clarity

- Reinforced nylons for enhanced mechanical properties

| Material | Heat Resistance | Key Properties | Typical Applications |

|---|---|---|---|

| ABS | 80-100°C | Good impact strength, easy processing | Housing, structural components |

| PC | 140-150°C | Excellent impact, optical clarity | High-stress areas, transparent parts |

| PEEK | 250°C+ | Outstanding chemical resistance | Heating element housings |

| Reinforced Nylon | 120-150°C | Superior strength-to-weight | Gears, brackets, load-bearing |

Composite materials incorporating reinforcing fibers provide exceptional strength-to-weight ratios for premium applications. Carbon fiber reinforced plastics offer aerospace-grade performance characteristics for high-end professional equipment.

Conductive filaments enable embedded electronics integration, creating components with built-in wiring, sensors, and control elements. This capability opens possibilities for truly integrated smart devices with minimal assembly requirements.

Food-safe and skin-contact certifications ensure materials meet regulatory requirements for consumer appliance applications, providing confidence for components that may contact users during operation.

How Are Leading Manufacturers Adopting 3D Printing Technology?

Industry adoption reveals strategic approaches to implementing additive manufacturing across different company sizes and market segments. Leading manufacturers demonstrate various implementation strategies that provide insights for wholesale suppliers.

Major manufacturers including Philips, Dyson, and Chinese OEM suppliers are adopting 3D printing for rapid prototyping, custom component production, and spare parts manufacturing. Philips’ “Fixables” program with Prusa Research enables consumers to 3D print replacement parts, while companies like Huux leverage the technology for accelerated development cycles and customized wholesale solutions.

Philips represents the most advanced adoption with their revolutionary “Fixables” program launched in partnership with Prusa Research. This initiative allows consumers to download and 3D print replacement parts for personal care devices, currently offering trimmer combs with plans to expand to hair dryer components and electric toothbrush parts.

Implementation strategies vary by company focus:

- Large manufacturers begin with prototyping before expanding to production

- OEM suppliers adopt direct production for specialized components

- Startup companies leverage 3D printing for competitive differentiation

- Wholesale suppliers use the technology for customization and rapid response

Chinese manufacturers increasingly integrate 3D printing into development workflows. Companies like Huux demonstrate how OEM suppliers can reduce development times while offering more customized solutions to international clients, particularly beneficial for wholesale relationships requiring rapid response to market demands.

The technology enables smaller manufacturers to compete with larger companies by reducing development barriers and enabling rapid innovation cycles. This democratization of advanced manufacturing capabilities levels the competitive playing field.

Investment patterns show companies typically start with desktop systems for prototyping before scaling to industrial-grade equipment for production applications. This graduated approach allows manufacturers to develop expertise while minimizing initial investment risk.

What Future Developments Will Shape 3D Printing in Hair Dryer Manufacturing?

Future technological developments promise to expand 3D printing applications and transform hair dryer manufacturing fundamentally. Emerging technologies will address current limitations while opening new possibilities for design and production.

Future developments include multi-material printing with embedded electronics, artificial intelligence process optimization, sustainable bio-based materials, and automated production systems. These advances will enable complete hair dryer assembly through 3D printing while reducing environmental impact, improving quality consistency, and lowering production costs.

Multi-material capabilities represent the most significant near-term advancement. Single-print production of components with varying material properties will eliminate assembly requirements while improving performance integration. Conductive materials will enable embedded wiring and electronic components printed directly into structural elements.

Transformative technology trends include:

- AI-driven process optimization for quality prediction and control

- Sustainable materials including biodegradable and recycled feedstocks

- Continuous printing technologies for dramatically increased throughput

- Hybrid manufacturing combining additive and subtractive processes

Artificial intelligence integration will revolutionize quality control and process optimization. Machine learning algorithms will analyze printing data to predict defects, optimize parameters automatically, and enable autonomous production systems requiring minimal human intervention.

Sustainability considerations drive material development toward bio-based and recyclable options. These materials will reduce environmental impact while maintaining performance requirements, addressing growing consumer and regulatory demands for sustainable manufacturing.

| Technology Area | Current State | Future Capability | Timeline |

|---|---|---|---|

| Multi-material | Limited combinations | Integrated electronics | 2-3 years |

| AI Optimization | Basic monitoring | Predictive quality control | 1-2 years |

| Sustainable Materials | Early development | Performance equivalent | 3-5 years |

| Production Speed | Moderate throughput | Mass production viable | 5-7 years |

Speed improvements will make 3D printing competitive with traditional manufacturing for higher volumes. Continuous printing technologies and automated post-processing will dramatically increase throughput while reducing per-part costs.

Digital supply chains will enable distributed manufacturing where components are produced closer to end markets, reducing transportation costs and improving supply chain resilience. Cloud-based design repositories will allow rapid deployment of updates across global manufacturing networks.

Summary

3D printing is revolutionizing hair dryer manufacturing through rapid prototyping, cost reduction, design innovation, and quality improvements. This technology enables manufacturers to accelerate development cycles, create custom solutions, and respond rapidly to market demands while serving wholesale clients more effectively.

Ready to leverage cutting-edge manufacturing technology for your hair dryer business? Explore our innovative P1C high-speed hair dryer featuring advanced development processes, or browse our complete product collection showcasing the latest manufacturing innovations. Contact Conason today to discuss wholesale opportunities and discover how our advanced manufacturing capabilities can support your market success.