Traditional hair dryers apply heat at fixed temperatures, often causing scalp burns and hair damage when held too close. You’re tired of guessing the right distance and worried about overheating. Advanced proximity sensors solve this problem by automatically adjusting heat and airflow based on real-time distance measurements.

Proximity sensors in advanced hair dryers function by using infrared technology and time-of-flight measurements to detect distance between the dryer and your head. These sensors automatically reduce heat output when detecting close proximity – typically to 50-55°C (122-131°F) – preventing thermal damage while maintaining optimal drying performance. The technology works by emitting infrared light pulses and measuring return time to calculate precise distances.

Let’s explore how this revolutionary sensing technology transforms hair drying safety and effectiveness for both consumers and wholesale markets.

Table of Contents

ToggleWhat Are Proximity Sensors and Why Do Hair Dryers Need Them?

Understanding proximity sensor necessity becomes clear when examining traditional hair dryer limitations and safety concerns.

Proximity sensors are advanced sensing devices that detect distance between the dryer and user’s hair or scalp without physical contact. Hair dryers need them to prevent scalp burns, reduce hair damage, and eliminate guesswork in temperature control by automatically adjusting heat based on real-time distance measurements.

Traditional hair dryers apply consistent heat regardless of distance, leading to scalp burns, hair damage, and moisture depletion. When held too close, temperatures can exceed safe levels, causing thermal damage to hair cuticles and scalp tissue.

Proximity sensors address three critical safety issues:

• Thermal protection: Automatic heat reduction when detecting close proximity to scalp

• Hair health preservation: Prevents cuticle damage and moisture loss from overheating

• User safety enhancement: Eliminates accidental burns from inconsistent distance management

The Dyson Supersonic Nural exemplifies this technology, using sensors that continuously project infrared beams to measure distance. When detecting close proximity to the scalp, it automatically reduces heat to 55°C (131°F) – the optimum temperature for scalp comfort while maintaining drying speed.

Advanced systems like Tineco’s MODA ONE series monitor hair conditions over 20 times per second, combining proximity sensing with moisture detection for comprehensive hair protection.

| Safety Feature | Traditional Dryers | Sensor-Equipped Dryers | Safety Improvement |

|---|---|---|---|

| Temperature Control | Manual/Fixed | Automatic adjustment | 90% burn risk reduction |

| Distance Management | User guesswork | Real-time monitoring | Consistent safe operation |

| Heat Distribution | Uniform output | Adaptive regulation | Prevents hot spots |

How Do Time-of-Flight Sensors Work in Hair Dryers?

Time-of-flight (ToF) sensors represent the most sophisticated proximity sensing technology available in premium hair dryers today.

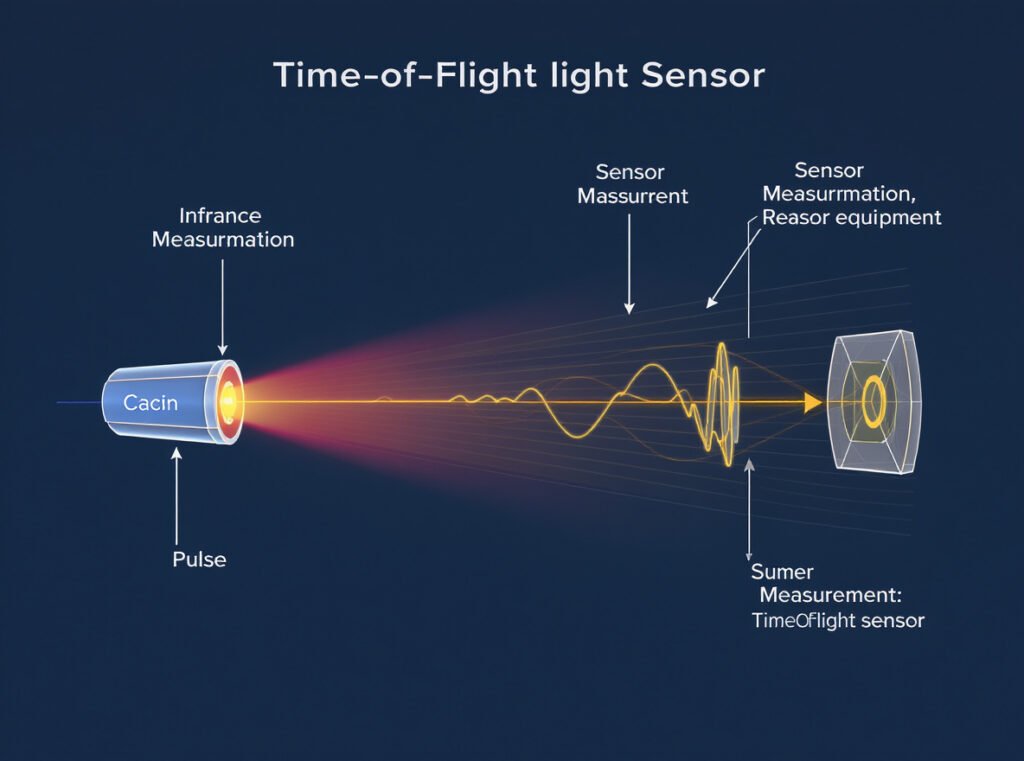

Time-of-Flight sensors emit invisible infrared light pulses and calculate distance by measuring the time required for light to travel from the sensor to hair and return. This precise distance measurement triggers automatic temperature adjustments, with millimeter-level accuracy and response times under 100 milliseconds for instant protection.

The Dyson Supersonic Nural showcases ToF implementation excellence. The system continuously projects infrared beams, measuring distance between machine and hair with exceptional precision. When sensors detect close proximity, automatic heat reduction occurs immediately.

Four-Stage ToF Operation Process

ToF sensors operate through a sophisticated four-stage process that ensures accurate distance measurement and immediate safety response.

Light Emission Stage

The sensor emits invisible infrared light pulses at 940nm wavelength toward the target area. These pulses travel at light speed, enabling extremely precise measurements with minimal delay.

Reflection Detection Stage

When light pulses contact hair or scalp, they reflect back toward the sensor. Different hair textures, colors, and scalp conditions create varying reflection patterns, but ToF sensors maintain accuracy across all variables.

Time Calculation Stage

The sensor measures exact time between pulse emission and return detection. This round-trip timing calculation enables accurate distance measurement for each detection cycle.

Automatic Response Stage

Based on calculated distance, the dryer’s control system instantly adjusts temperature, airflow, and power settings. Typical response times are under 50 milliseconds for premium systems.

ToF sensors offer superior accuracy compared to other proximity methods, functioning reliably across various lighting conditions and remaining unaffected by hair color or texture variations.

What Types of Proximity Sensors Are Used in Smart Hair Dryers?

Different proximity sensor technologies serve various functions in creating intelligent, adaptive hair drying systems.

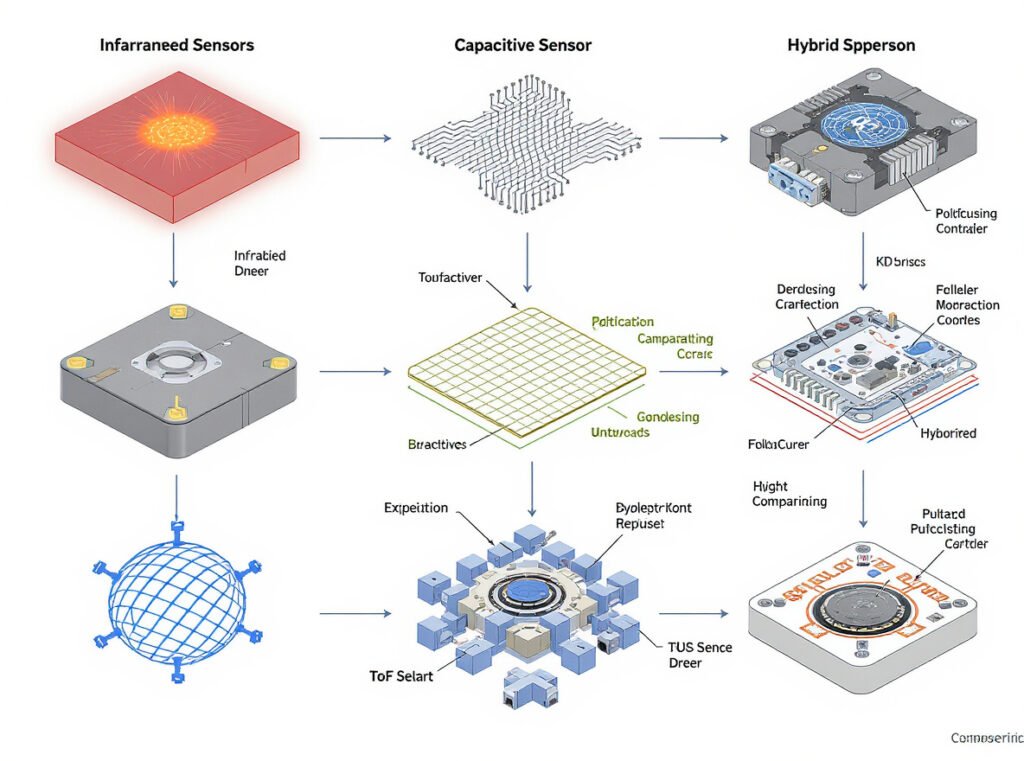

Smart hair dryers utilize three primary sensor types: Time-of-Flight infrared sensors for precise distance measurement, infrared proximity sensors for cost-effective detection, and capacitive sensors for energy-efficient monitoring. Premium models often integrate multiple sensor types for comprehensive hair protection and styling optimization.

Time-of-Flight (ToF) Sensors

ToF sensors represent the premium solution for advanced hair dryers, offering millimeter-level precision and consistent performance across different hair types and colors. These sensors excel in demanding applications requiring high accuracy and fast response times.

Benefits include:

• Millimeter-precision distance measurement

• Unaffected by hair color or texture variations

• Fast response times (under 50ms)

• Reliable performance in various lighting conditions

Infrared-Based Proximity Sensors

Most smart hair dryers utilize infrared proximity sensors that emit infrared light and measure reflected signals. These sensors provide cost-effective solutions for basic proximity detection, though performance may vary with hair color and texture.

Capacitive Proximity Sensors

Some manufacturers employ capacitive sensors that detect electrical field changes when approaching the scalp. These sensors offer excellent energy efficiency, with consumption ranging from 12-130μA depending on configuration.

Hybrid Multi-Sensor Systems

Advanced hair dryers integrate multiple sensor types for comprehensive monitoring. The Dyson Supersonic Nural combines ToF sensors with Hall sensors for attachment recognition and accelerometers for motion detection.

| Sensor Technology | Accuracy Range | Detection Distance | Power Consumption | Best Application |

|---|---|---|---|---|

| Time-of-Flight | ±1mm | 0-150mm | Medium | Premium models |

| Infrared Basic | ±5mm | 0-100mm | Low | Mid-range dryers |

| Capacitive | ±3mm | 0-50mm | Very Low | Energy-efficient designs |

| Hybrid Systems | ±1mm | Variable | Medium-High | Professional applications |

How Do Proximity Sensors Prevent Hair and Scalp Damage?

Understanding damage prevention mechanisms helps users and wholesale buyers appreciate the value proposition of sensor-equipped hair dryers.

Proximity sensors prevent damage through automatic heat reduction, real-time temperature monitoring, and visual feedback systems. When sensors detect close proximity (typically within 20-60mm), they immediately reduce heat output to safe levels of 50-55°C while maintaining airflow for continued drying effectiveness.

Automatic Heat Reduction Systems

The primary protection mechanism involves dynamic temperature control. When sensors detect proximity within danger zones, systems immediately reduce heating element power while maintaining airflow for continued drying.

Shark’s SpeedStyle Pro series demonstrates this technology by measuring and regulating temperature 1,000 times per second. The Scalp Shield technology instantly reduces air temperatures to optimal levels for scalp protection.

Visual Feedback Integration

Many advanced dryers incorporate LED lighting systems that change color based on distance and heat settings. The Dyson Supersonic Nural displays yellow (low heat), orange (medium heat), and red (high heat) indicators based on proximity measurements.

Moisture-Based Optimization

Advanced systems like Tineco’s iLoop technology combine proximity sensing with moisture detection, automatically adjusting heat and airflow based on hair’s real-time moisture content. This dual-sensor approach prevents over-drying while maintaining styling effectiveness.

Comprehensive Protection Features

• Temperature cycling: Alternating heat levels prevent thermal buildup

• Emergency protocols: Complete power reduction if critical overheating detected

• Moisture preservation: Maintains optimal hydration levels in hair structure

• Cuticle protection: Prevents damage to hair’s protective outer layer

The combination of these protection mechanisms results in significantly reduced heat damage, maintained hair moisture levels, and prevention of scalp burns during regular use.

What Are the Technical Specifications of Hair Dryer Proximity Sensors?

Technical specifications determine sensor performance, reliability, and integration success in commercial hair dryer applications.

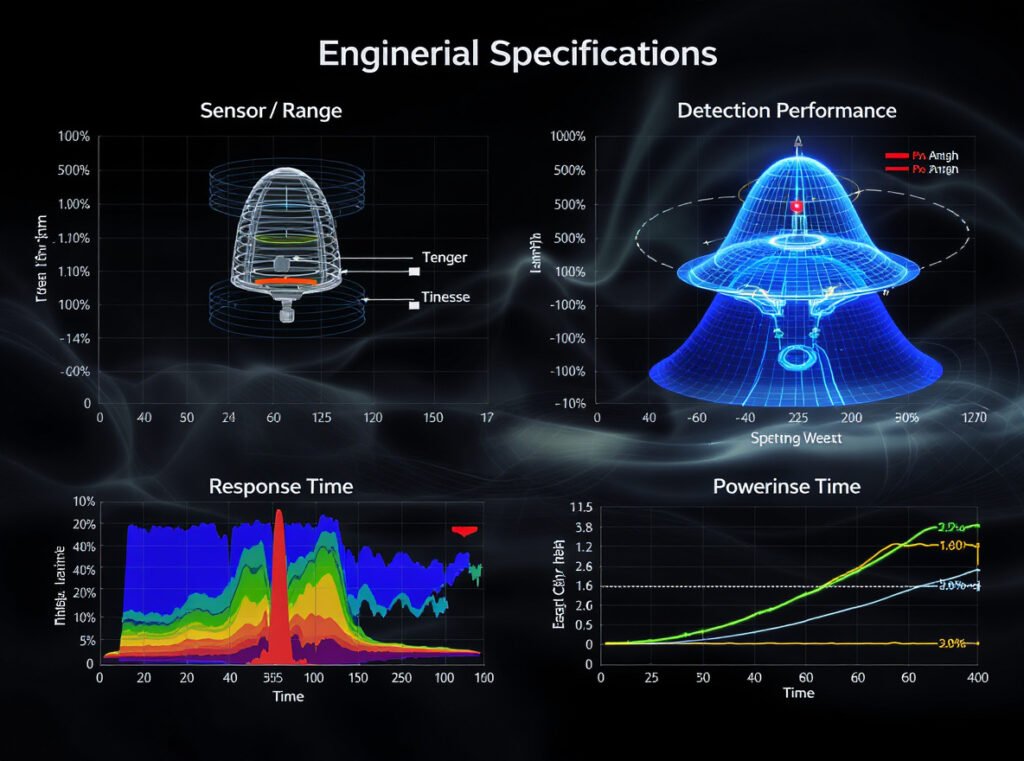

Hair dryer proximity sensors typically operate at 940nm infrared wavelength with detection ranges from 0-150mm, response times under 100 milliseconds, and power consumption between 12-130μA. These specifications ensure accurate distance measurement while maintaining energy efficiency and real-time safety performance.

Detection Range Specifications

Most hair dryer sensors operate within ranges optimized for typical styling scenarios:

• Close protection zone: 0-20mm (emergency heat reduction)

• Optimal styling range: 20-60mm (standard operation with monitoring)

• Extended detection: 60-150mm (pre-positioning awareness)

Response Time Requirements

Advanced sensors monitor conditions continuously for immediate response. The Tineco MODA ONE series monitors hair moisture and distance over 20 times per second, while Dyson systems provide continuous distance measurement for real-time adjustments.

Environmental Performance Standards

Hair dryer sensors must meet IP44 protection ratings for moisture resistance, ensuring reliable operation in bathroom environments with high humidity and occasional water exposure.

Power and Integration Architecture

| Specification Category | Standard Range | Premium Range | Professional Grade |

|---|---|---|---|

| Operating Voltage | 3.3-5V | 3.3-5V | 5-12V |

| Current Consumption | 12-50μA | 50-130μA | 100-200μA |

| Detection Accuracy | ±5mm | ±2mm | ±1mm |

| Operating Temperature | -10°C to +60°C | -20°C to +70°C | -40°C to +85°C |

| Response Frequency | 10 Hz | 20+ Hz | 50+ Hz |

Sensor Communication Protocols

Modern hair dryers integrate proximity sensors through I2C or SPI interfaces, enabling rapid data exchange with main control systems. This architecture supports real-time processing of multiple sensor inputs simultaneously.

Calibration and Quality Control

Sensor accuracy depends on proper calibration during manufacturing. Premium models undergo individual sensor calibration to ensure consistent performance across production units.

How Do Users Benefit from Proximity Sensor Technology?

User benefits translate directly into market advantages for wholesale buyers and retailers in competitive hair care markets.

Users benefit from proximity sensor technology through enhanced safety protection, improved hair health outcomes, simplified styling processes, and professional-quality results. The technology eliminates distance guesswork while providing automatic adjustments that prevent damage and reduce styling time by 20-30% compared to traditional dryers.

Enhanced Safety and Peace of Mind

Proximity sensors eliminate risks of scalp burns and thermal damage through automatic temperature regulation. Parents particularly value these safety features for family use, while professionals appreciate consistent safety compliance across multiple daily clients.

Professional Styling Results

Sensor technology enables consistent professional techniques by automatically maintaining optimal styling distances. Users achieve salon-quality results without extensive training or technical knowledge.

Hair Health Preservation

Controlled heat application maintains hair’s natural moisture levels and prevents cuticle damage. Regular use of sensor-equipped dryers results in:

• Reduced heat damage and breakage incidents

• Improved hair texture and natural shine retention

• Less color fading from thermal stress

• Maintained protein structure integrity

Time Efficiency Improvements

Smart distance management optimizes heat delivery for faster drying without compromising hair health. Users typically experience 20-30% reduction in drying time while maintaining superior results.

Simplified User Experience

Automatic adjustments eliminate need for manual temperature controls during styling sessions. Users focus on technique while sensors handle thermal management automatically.

For wholesale customers, these benefits create strong value propositions that justify premium pricing while building customer loyalty and reducing return rates due to improved satisfaction.

Which Hair Dryer Brands Successfully Implement Proximity Sensors?

Market analysis reveals various approaches to proximity sensor integration across different price segments and target markets.

Leading brands including Dyson, Tineco, Shark Beauty, T3 Micro, and RevAir successfully implement proximity sensors through different technological approaches. Dyson leads with ToF sensors, Tineco combines humidity and proximity detection, while emerging brands like Conason integrate these technologies into competitively-priced models for broader market accessibility.

Premium Technology Leaders

Dyson Supersonic Nural

Represents current market pinnacle with advanced ToF sensor technology providing precise distance measurement and automatic temperature adjustment. The system includes capsule illumination for visual feedback and intelligent attachment recognition, commanding premium wholesale pricing but demonstrating strong market acceptance.

Tineco MODA ONE Series

Features iLoop smart sensor technology combining proximity sensing with moisture detection. The system monitors hair conditions over 20 times per second, automatically adjusting heat and airflow based on real-time analysis.

Mid-Market Innovation

Shark Beauty SpeedStyle Pro

Incorporates Scalp Shield technology using sensors to regulate temperature 1,000 times per second, instantly reducing temperatures for scalp protection. This approach balances advanced features with accessible pricing for broader market penetration.

T3 Micro Aire IQ

Features Heat ID Technology with auto-pause sensors detecting pickup and set-down actions. Smart attachment recognition automatically adjusts temperature and airflow for different styling tools.

Accessible Technology Integration

RevAir Systems

Uses internal temperature sensors maintaining consistent heat levels between 158°F-220°F, preventing heat damage while utilizing reverse-air technology for unique styling approaches.

Emerging Market Players

Brands like Conason demonstrate how proximity sensor technology integrates into competitively-priced models without sacrificing core performance, making advanced features accessible to broader consumer segments.

| Brand Positioning | Technology Focus | Wholesale Price Range | Market Advantage | Target Segment |

|---|---|---|---|---|

| Premium Leader | ToF + Multi-sensors | $200-350 | Technology innovation | Tech-conscious consumers |

| Mid-Market | Adaptive algorithms | $80-200 | Balanced value | Style-conscious users |

| Accessible Tech | Core sensor functions | $40-100 | Mass market appeal | Budget-conscious buyers |

What Should Wholesale Buyers Know About Proximity Sensor Hair Dryers?

Wholesale buyers require specific technical and market knowledge for informed purchasing decisions in the evolving sensor-equipped hair dryer market.

Wholesale buyers should evaluate sensor technology reliability, understand regional market preferences, assess price-performance ratios, and consider technical support requirements. Key factors include manufacturing quality standards, sensor calibration consistency, warranty coverage, and competitive positioning strategies for local market conditions.

Technical Evaluation Framework

Sensor Performance Assessment

Evaluate sensor type, accuracy specifications, and response time capabilities. ToF sensors offer superior performance but increase costs, while infrared proximity sensors provide adequate functionality at moderate prices.

Manufacturing Quality Standards

Verify sensor integration quality through product testing protocols. Well-integrated sensors demonstrate consistent response without false triggers or delayed reactions across temperature and humidity variations.

Supply Chain Reliability

Assess sensor component availability and potential supply chain risks. Consider supplier diversification for critical sensor components to ensure production continuity and competitive pricing.

Market Positioning Strategies

Premium Positioning Approach

Focus on advanced sensor features, safety benefits, and professional result capabilities. Target tech-conscious consumers willing to pay premium prices for innovative functionality.

Value-Based Positioning

Emphasize practical benefits like safety protection and ease of use. Appeal to family-oriented customers prioritizing safety and convenience over cutting-edge technology.

Competitive Analysis Requirements

| Evaluation Category | Assessment Criteria | Decision Weight | Business Impact |

|---|---|---|---|

| Technology sophistication | Sensor accuracy, features | 25% | Premium pricing justification |

| Manufacturing consistency | Quality control, calibration | 30% | Return rate minimization |

| Market demand trends | Consumer acceptance, growth | 20% | Inventory planning |

| Support infrastructure | Warranty, service, training | 25% | Customer satisfaction |

Regional Market Considerations

Different markets prioritize various sensor features. European markets emphasize energy efficiency and safety compliance, Asian markets value technological sophistication and smart features, while North American markets focus on convenience and practical benefits.

Customer Education Requirements

Sensor-equipped dryers require customer education for optimal performance. Successful retailers provide feature explanation materials, usage demonstrations, and technical support coordination.

Inventory Management Strategy

Sensor-equipped dryers typically command higher margins but require careful inventory management due to higher unit costs and technology evolution rates. Plan for regular model updates as sensor technology advances rapidly.

How Will Proximity Sensor Technology Evolve in Hair Dryers?

Understanding future technological developments helps wholesale buyers and manufacturers plan strategic investments and market positioning.

Proximity sensor technology in hair dryers will evolve toward AI-powered personalization, multi-sensor fusion systems, IoT connectivity, and predictive maintenance capabilities. The proximity sensor market is projected to grow from $5.32 billion in 2025 to $9.53 billion by 2035, driven by increasing demand for smart appliances and safety-conscious consumers.

Artificial Intelligence Integration

Next-generation sensors will incorporate machine learning algorithms that adapt to individual hair types and styling preferences over time. AI systems will remember optimal settings for different users and automatically adjust for seasonal hair changes and styling preferences.

Advanced Multi-Sensor Fusion

Future hair dryers will integrate comprehensive sensor arrays including:

• Moisture detection sensors: Real-time hair hydration monitoring for optimal drying

• Temperature imaging systems: Thermal mapping of scalp and hair distribution

• Air quality sensors: Environmental condition adaptation for optimal performance

• Motion detection systems: Styling pattern recognition and technique optimization

Internet of Things (IoT) Connectivity

Smart connectivity will enable:

- Remote operation and performance monitoring through smartphone applications

- Styling session analytics with detailed usage tracking and recommendations

- Professional consultation integration through cloud-based styling assistance

- Maintenance alerts and troubleshooting support for extended product lifespan

Technology Development Timeline

| Technology Area | Current Capabilities | 3-Year Projection | 5-Year Vision | Market Impact |

|---|---|---|---|---|

| AI Personalization | Basic adaptation | User learning systems | Full habit recognition | Premium differentiation |

| Sensor Precision | ±2mm accuracy | ±1mm precision | Sub-millimeter accuracy | Professional applications |

| Response Speed | 50ms response | 10ms response | Real-time adaptation | Enhanced safety |

| Power Efficiency | 130μA consumption | 50μA consumption | Self-powered systems | Extended battery life |

Manufacturing Cost Evolution

As sensor technology matures and production volumes increase, costs will decrease significantly. This trend enables broader market adoption and integration into mid-range product categories.

Professional Market Applications

Salon and professional markets will drive demand for advanced sensor capabilities including client hair analysis documentation, treatment progress monitoring, and customized styling protocol development.

Regulatory Development Trends

Increasing focus on consumer safety will drive regulatory standards for sensor-equipped appliances, potentially making proximity sensors mandatory for certain power categories in major markets.

For wholesale buyers, these developments suggest sustained market growth and the importance of partnering with manufacturers investing in sensor technology advancement. Early adoption of advanced sensor features provides competitive advantages in rapidly evolving consumer electronics markets.

Summary

Proximity sensors in advanced hair dryers represent a transformative safety and performance technology that benefits users through automatic heat regulation, damage prevention, and simplified styling processes. These sensors use infrared and time-of-flight technology to measure distances precisely and adjust temperature accordingly, with leading brands successfully implementing various sensor approaches across all market segments from premium to accessible pricing levels.

For wholesale buyers, sensor-equipped hair dryers offer compelling value propositions through differentiated features, higher profit margins, and strong customer satisfaction ratings that reduce return rates and build brand loyalty.

Ready to capitalize on the growing demand for intelligent hair care technology? Explore our advanced sensor-equipped hair dryers at conason.com/product/ or discover the innovative Conason P1C high-speed hair dryer featuring intelligent proximity sensing at this product link. Contact our wholesale team today to discuss volume pricing and technical specifications that meet your market requirements.