Nothing’s more frustrating than rushing to style your hair only to find your trusty hair dryer refuses to power up. Whether you’re running a salon or managing inventory for your retail business, a non-functioning hair dryer can disrupt operations and disappoint customers.

A hair dryer that won’t turn on is usually caused by a tripped ALCI safety plug, thermal fuse activation, power cord damage, or internal component failure. Most issues can be resolved through simple troubleshooting steps like resetting the ALCI button, checking connections, and allowing the device to cool down.

Let’s walk through the complete troubleshooting process to get your hair dryer working again and help you understand when it’s time to consider a replacement.

Table of Contents

ToggleWhy Won’t My Hair Dryer Turn On at All?

Understanding the root cause is essential for any retailer or distributor dealing with customer complaints about non-functional hair dryers.

The most common reasons a hair dryer won’t turn on include damaged power cords, tripped ALCI (Appliance Leakage Circuit Interrupter) safety plugs, blown thermal fuses due to overheating, and faulty internal switches or motors.

Hair dryers draw significant power, typically 1200-1875 watts, which can overwhelm circuits or trigger safety mechanisms. The ALCI safety device built into most modern hair dryer plugs is designed to detect electrical faults and cut power immediately to prevent shock or electrocution.

Thermal fuses serve as another critical safety feature. When lint buildup blocks air intake or the motor overheats, the thermal fuse blows to prevent fires. This is particularly important for wholesale buyers to understand when addressing customer concerns.

Common Failure Points

| Component | Failure Rate | Typical Cause |

|---|---|---|

| Power Cord | 35% | Wear from wrapping, internal wire breakage |

| ALCI Safety Plug | 25% | Moisture detection, electrical faults |

| Thermal Fuse | 20% | Overheating, lint blockage |

| Internal Switch | 15% | Wear from frequent use |

| Motor Assembly | 5% | Age, electrical damage |

Modern professional models like the Conason P1C high-speed hair dryer include multiple redundant safety systems that reduce failure rates while protecting users from electrical hazards.

What Should I Check First When My Hair Dryer Won’t Start?

Before assuming your hair dryer is broken, start with these immediate checks that solve 80% of power issues.

First, test the electrical outlet with another device, inspect the power cord for visible damage, and check if the ALCI reset button on the plug needs to be pressed. These basic steps resolve most startup problems.

Power Source Verification

Start by testing the electrical outlet with another device like a lamp or phone charger. If the outlet has no power, check your circuit breaker or GFCI outlet reset button. Bathroom outlets often have GFCI protection that can trip independently of the hair dryer’s ALCI.

ALCI Reset Process

Most hair dryers manufactured after 1991 include ALCI safety plugs with test and reset buttons. To properly reset:

- Turn off and unplug the hair dryer completely

- Press the reset button firmly until it clicks and stays engaged

- Plug the dryer back in and test operation

- If the reset button won’t stay engaged, the ALCI may be faulty

Visual Inspection Protocol

Examine the entire power cord from plug to dryer body. Look for:

- Fraying or cuts in the outer insulation

- Burn marks or discoloration near the plug

- Kinks or damage where the cord enters the dryer

- Loose or bent plug prongs

Damaged cords are the leading cause of hair dryer failures and create serious safety hazards. Any visible damage requires immediate replacement or professional repair.

How Do I Reset a Hair Dryer That Suddenly Stopped Working?

When a hair dryer stops mid-use, it’s typically a safety feature activation rather than a permanent failure.

Allow the hair dryer to cool completely for 10-15 minutes, then press the reset button on the ALCI plug. If the dryer overheated due to blocked air intake, clean the lint filter and air vents before testing.

Thermal Fuse Reset Procedure

Unlike the ALCI which can be reset, blown thermal fuses require replacement. Signs of thermal fuse failure include:

- Complete power loss during operation

- No response to ALCI reset attempts

- Recent overheating episodes

- Visible lint buildup in air intake

Professional repair is recommended for thermal fuse replacement, as it requires disassembly and electrical work.

Cooling and Cleaning Protocol

Before attempting any reset:

- Unplug the device and let it cool in a well-ventilated area

- Remove visible lint from air intake using a soft brush

- Check for blockages in the rear grille or filter

- Ensure proper ventilation around the motor housing

Reset Button Locations and Functions

| Reset Type | Location | Purpose | Reset Method |

|---|---|---|---|

| ALCI Plug | On the plug body | Electrical fault protection | Press and hold until engaged |

| Thermal Cutout | Internal (non-serviceable) | Overheat protection | Automatic after cooling |

| GFCI Outlet | Wall outlet | Ground fault protection | Press outlet reset button |

For businesses managing inventory, understanding these safety systems helps provide better customer support and reduces unnecessary returns.

What Internal Problems Prevent Hair Dryers from Turning On?

When external troubleshooting fails, internal component issues may be the culprit.

Common internal failures include faulty power switches, damaged heating elements, motor problems, and failed thermal cutout switches. These issues typically require professional repair or replacement, especially in units over 3 years old.

Switch and Control Failures

Power switches, speed controls, and heat settings can fail from repeated use. Symptoms include:

- Switch positions that don’t engage

- Intermittent power when adjusting controls

- Sparking or burning smell from switch area

- Controls that feel loose or unresponsive

Professional diagnosis with a multimeter can determine if switches maintain proper electrical continuity.

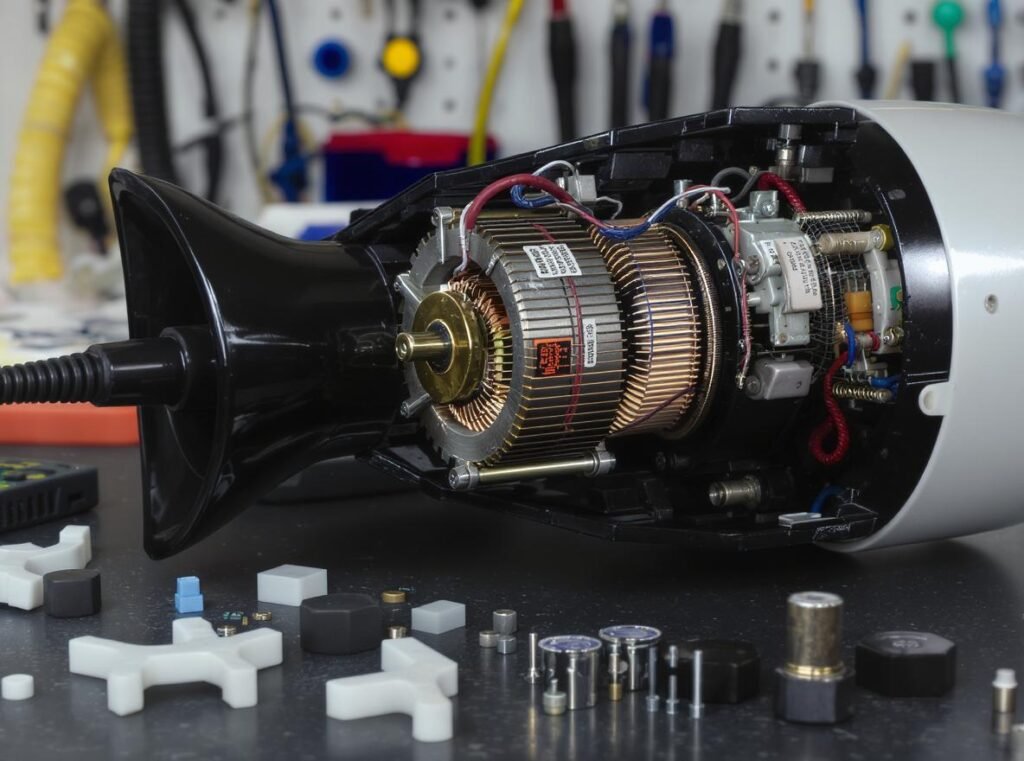

Motor and Fan Assembly Issues

Motor failures often present as complete power loss or unusual sounds:

- Humming without air movement indicates seized bearings

- Grinding noises suggest fan blade damage

- Burning odors point to motor winding failure

- Complete silence may indicate broken electrical connections

Heating Element Problems

Damaged heating coils can trigger safety shutoffs that prevent startup. Common heating element issues include:

- Broken coil wires from thermal expansion

- Short circuits causing ALCI activation

- Corrosion from moisture exposure

- Age-related metal fatigue

For wholesale buyers, investing in models with replaceable heating elements can extend product lifespan and reduce total ownership costs.

When Should I Replace Instead of Repair My Hair Dryer?

Cost-effectiveness determines whether repair makes business sense for retailers and distributors.

Replace hair dryers when repair costs exceed 50% of replacement value, when the ALCI safety device fails permanently, or when there’s extensive internal damage like burnt motors or melted wiring. For wholesale operations, consistent reliability outweighs repair savings.

Repair vs. Replace Decision Matrix

| Factor | Repair Recommended | Replace Recommended |

|---|---|---|

| Age | Under 2 years | Over 3-4 years |

| Repair Cost | Under 40% of new price | Over 50% of new price |

| Safety Issues | ALCI reset successful | ALCI won’t reset/stay engaged |

| Damage Extent | Single component failure | Multiple system failures |

| Warranty Status | Still covered | Expired |

Economic Considerations for Businesses

Professional users should factor in:

- Downtime costs during repair periods

- Reliability requirements for customer satisfaction

- Warranty coverage for business applications

- Availability of replacement parts

Safety Replacement Indicators

Immediate replacement is necessary when:

- ALCI cannot be reset or frequently trips

- Evidence of water damage or electrical shorting

- Visible burn marks on internal components

- Cord damage that cannot be safely repaired

- Any signs of electrical shock during operation

Modern professional-grade units like those in Conason’s product collection offer superior reliability and comprehensive warranties that make replacement more cost-effective than repairing older units.

How Can I Prevent My Hair Dryer from Failing to Turn On?

Prevention saves money and ensures reliable operation for both personal and business use.

Regular maintenance, proper storage, avoiding overuse, and keeping air intakes clean prevent most hair dryer startup failures. Professional models require less frequent maintenance due to superior component quality and better thermal management.

Preventive Maintenance Schedule

Monthly maintenance should include:

- Cleaning lint filters and air intake grilles

- Inspecting power cord for wear or damage

- Testing ALCI reset function to ensure proper operation

- Checking for loose screws or housing damage

Proper Usage Guidelines

Extend hair dryer lifespan by:

- Avoiding continuous operation beyond manufacturer recommendations

- Using appropriate voltage outlets without extension cords

- Storing in dry environments away from humidity

- Never wrapping cords tightly around the device body

Professional Environment Considerations

High-volume salon use requires additional precautions:

- Dedicated 20-amp circuits to prevent electrical overload

- Multiple units to allow rotation and cooling

- Professional-grade models rated for continuous duty

- Regular professional inspection and maintenance

Storage and Handling Best Practices

| Practice | Benefit | Implementation |

|---|---|---|

| Cord Management | Prevents wire breakage | Use loose coils, avoid tight wrapping |

| Dry Storage | Prevents electrical corrosion | Store in climate-controlled environment |

| Impact Protection | Maintains internal alignment | Use protective cases or hooks |

| Filter Cleaning | Prevents thermal overload | Monthly cleaning schedule |

Quality construction in professional models significantly reduces maintenance requirements while ensuring consistent performance.

What Are the Most Reliable Hair Dryer Features for Avoiding Power Issues?

Understanding reliability features helps wholesalers and retailers choose products that minimize customer complaints.

Look for hair dryers with ALCI or GFCI safety plugs, removable air filters, durable power cords with strain relief, automatic thermal limiters, and well-ventilated designs. These features significantly reduce startup problems and extend device lifespan.

Advanced safety technologies in modern hair dryers prevent most power-related failures while protecting users from electrical hazards.

Essential Safety Features

Modern hair dryers should include:

- ALCI plugs for electrical fault protection

- Thermal cutout switches to prevent overheating

- Reinforced cord construction with strain relief

- Multiple ventilation points for optimal cooling

- Automatic reset capabilities for user convenience

Build Quality Indicators

Professional-grade construction features include:

- Heavy-duty switches rated for frequent operation

- Proper electrical insulation on all components

- Balanced motor assemblies for smooth operation

- High-temperature resistant housing materials

- Professional-grade heating elements designed for longevity

Advanced Protection Systems

| Feature | Function | Business Value |

|---|---|---|

| Multiple Thermal Sensors | Monitors various heat zones | Prevents damage, extends life |

| Smart Auto-Reset | Automatically resumes after cooling | Reduces user frustration |

| Overvoltage Protection | Guards against power surges | Fewer electrical failures |

| Moisture Detection | ALCI activation in humid conditions | Enhanced safety compliance |

Professional-Grade Specifications

For wholesale buyers seeking reliable inventory:

- Duty cycle ratings for continuous operation capability

- Component warranties covering electrical systems

- Easy access for professional maintenance

- Compliance with commercial electrical codes

Quality manufacturing like that found in the Conason P1C ensures consistent performance while minimizing warranty claims and customer service issues.

Summary

Hair dryer startup problems usually stem from safety feature activation, electrical issues, or component wear rather than permanent failures. Start troubleshooting with ALCI reset, power cord inspection, and cooling periods to address thermal shutoffs. Most issues resolve through these simple steps, but recurring problems or safety device failures indicate replacement time. For businesses, investing in quality models with comprehensive safety features, removable filters, and professional-grade construction reduces customer complaints and ensures reliable long-term operation.

Ready to upgrade your hair dryer inventory with reliable, professional-grade models? Browse our complete product collection or contact our team to discuss wholesale pricing and find the perfect solutions for your customers’ needs.