Accidents happen – your hair dryer slips from wet hands and crashes to the bathroom floor. The question racing through your mind isn’t just about replacement costs, but whether that expensive styling tool is now a safety hazard. For salon owners, distributors, and retailers, understanding drop damage can mean the difference between costly equipment failures and satisfied customers.

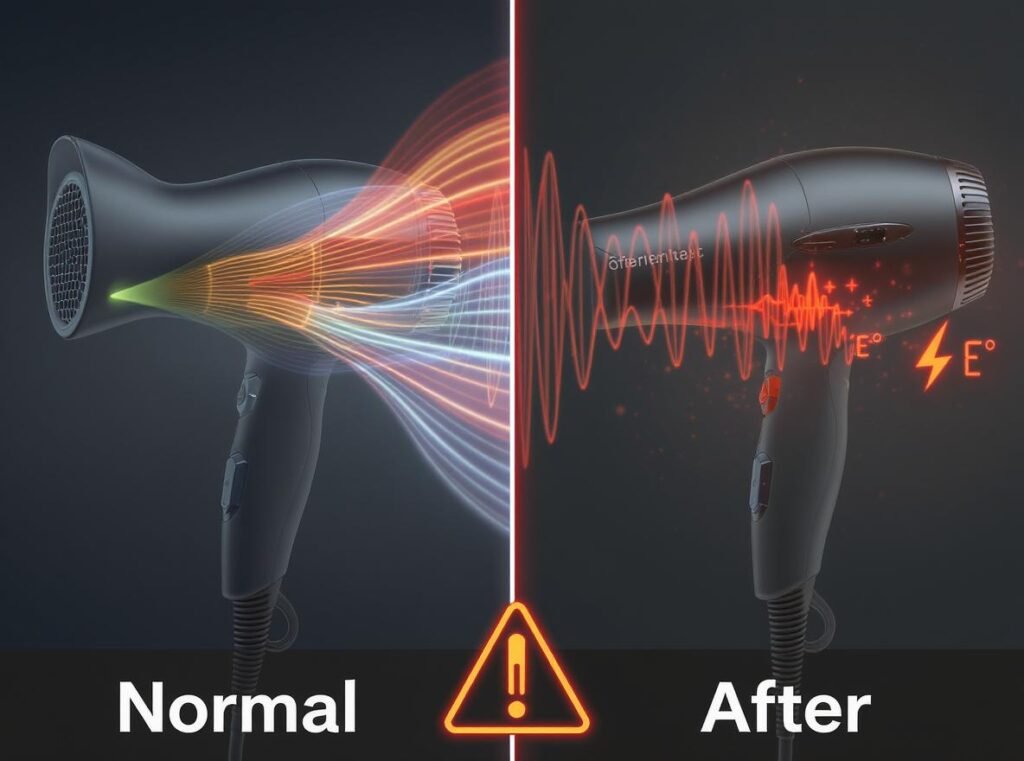

Yes, dropping a hair dryer can cause permanent internal damage to delicate components including the motor, fan assembly, heating elements, and internal electrical connections. The severity depends on drop height, landing surface, and impact angle, with drops from counter height (3-4 feet) onto hard surfaces posing the greatest risk.

Understanding what happens inside your hair dryer during impact – and how to assess the damage – could save you from unexpected equipment failures and safety hazards.

Table of Contents

ToggleWhat Internal Components Are Most Vulnerable to Drop Damage?

Hair dryers contain several precision components that weren’t designed to withstand sudden impacts.

The motor bearings, heating element coils, and internal electrical connections are most susceptible to drop damage. Motor bearings can seize after impact, heating elements can crack or misalign, and electrical connections may loosen, creating safety hazards or performance issues.

Motor and Fan Assembly Damage

Motor Bearing Vulnerability

The motor contains delicate bearings that enable smooth rotation. When dropped, these bearings can be damaged and may seize up, causing complete motor failure. Even minor bearing damage creates unusual grinding or rattling sounds that worsen over time.

Fan Blade Impact Damage

Fan blades can crack or break free from the motor shaft during drops. Damaged blades create dangerous imbalances, causing excessive vibration that further damages internal components and potentially creates safety hazards during operation.

Heating Element Failures

The heating element consists of continuous high-resistance wire wound around a non-conducting frame. Physical impact can cause these coils to break or become misaligned, leading to several problems:

- Uneven heating patterns that damage hair

- Complete heating failure requiring element replacement

- Dangerous hot spots that can cause burns or fires

- Reduced energy efficiency and increased operating costs

Electrical Connection Issues

Drop damage frequently affects internal wiring and connections:

| Component Type | Damage Risk | Failure Symptoms |

|---|---|---|

| Thermal Fuses | High | Unexpected shutdowns, no power |

| Control Switches | Medium | Intermittent operation, stuck settings |

| Wire Connections | High | Sparking, burning smells, power loss |

| Safety Switches | Critical | Overheating, fire risk |

How Can You Tell If Your Dropped Hair Dryer Is Damaged?

Early damage detection prevents safety hazards and helps determine repair feasibility.

Warning signs include unusual noises like rattling or grinding, reduced airflow, inconsistent heating, burning smells, or visible housing cracks. However, some internal damage may not manifest immediately, making thorough performance testing essential before continued use.

Immediate Audio Warning Signs

Motor-Related Sounds

Listen carefully when first testing a dropped hair dryer. New sounds indicate internal damage:

- Rattling suggests loose components or damaged fan blades

- Grinding indicates bearing damage or misaligned parts

- Scraping sounds mean internal components are making unwanted contact

- Unusual motor humming patterns signal electrical issues

Performance Degradation Indicators

Airflow and Heating Issues

Test all performance parameters systematically:

Reduced Airflow Problems

- Weak air output despite high speed settings

- Inconsistent airflow patterns

- Longer drying times than normal

- Difficulty maintaining styled results

Heating System Failures

- Inconsistent temperature across heat settings

- Failure to reach normal operating temperature

- Uneven heat distribution from the nozzle

- Extended warm-up times

Critical Safety Warning Signs

Immediate Discontinue-Use Indicators

Some symptoms require immediate cessation of use:

- Sparks during operation or when plugging in

- Burning or electrical smells during use

- Housing that becomes excessively hot

- Frequent tripping of GFCI outlets or circuit breakers

- Visible frayed or exposed wiring

- Housing cracks that expose internal components

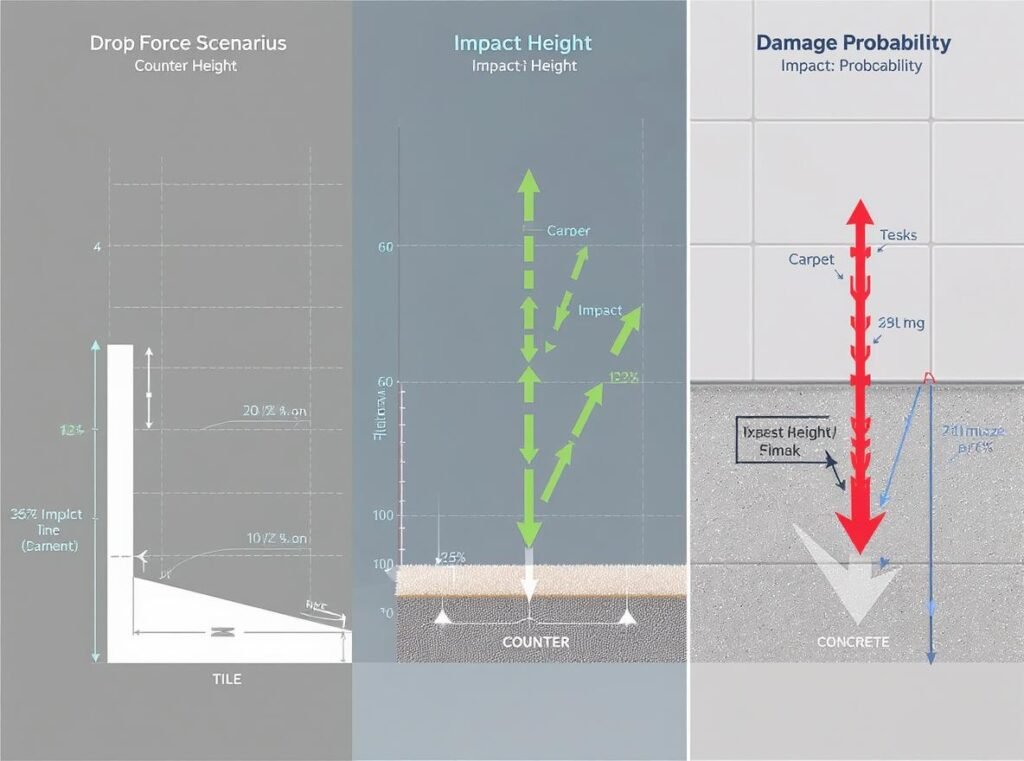

What Types of Drops Cause the Most Damage?

Understanding impact factors helps assess damage severity and safety risks.

Drops from bathroom counter height (3-4 feet) onto hard surfaces like tile create the most severe damage. Running hair dryers suffer additional damage as spinning components can be knocked out of alignment, while angle of impact determines which internal systems bear the brunt of the force.

High-Risk Drop Scenarios

Surface Material Impact

Different landing surfaces create dramatically different damage patterns:

- Tile or concrete floors: Maximum impact force, highest damage probability

- Hardwood floors: Moderate impact with potential for housing cracks

- Carpeted surfaces: Reduced impact force, primarily cosmetic damage

- Bathroom mats: Minimal damage risk, cushioned impact

Height-Based Damage Assessment

| Drop Height | Damage Probability | Primary Risk Areas |

|---|---|---|

| Under 2 feet | Low (15-25%) | Cosmetic housing damage |

| 2-4 feet (counter height) | High (60-80%) | Motor bearings, heating elements |

| Over 4 feet | Critical (85-95%) | Multiple component failure |

Operational State During Impact

Running vs. Off Damage Differences

Hair dryers dropped while operating face additional risks:

- Spinning motor components can suffer misalignment damage

- Sudden electrical disruption may damage control circuits

- Hot heating elements can crack from thermal shock

- Fan blades spinning at high speed are more likely to break on impact

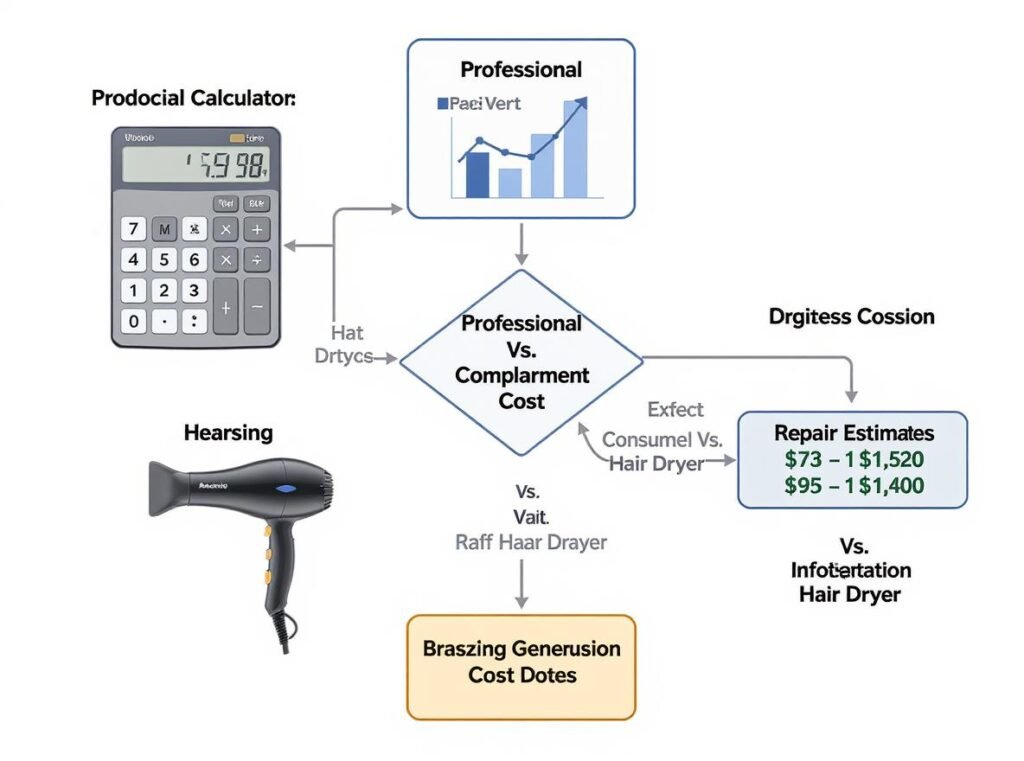

Can a Dropped Hair Dryer Be Safely Repaired?

Professional assessment determines whether repair is economically viable and safe.

Minor issues like loose connections or small housing cracks can often be safely repaired by qualified technicians. However, motor bearing damage or heating element failures typically require complete component replacement, making repair costs exceed replacement value for most consumer models.

Economically Repairable Damage

Professional Repair Candidates

Certain types of drop damage justify professional repair:

- Loose fan blade reattachment (if motor shaft isn’t damaged)

- Minor housing crack repair (cosmetic only, no electrical exposure)

- Resoldering loose electrical connections

- Replacing damaged attachments or accessories

- Thermal fuse replacement after thorough safety inspection

Beyond Economical Repair

Replacement-Necessary Damage

Some damage types make repair impractical:

Motor System Failures

Motor bearing damage often requires complete motor replacement. Since motors represent 40-60% of a hair dryer’s component cost, repair typically exceeds replacement value.

Heating Element Damage

Cracked heating elements require complete heating assembly replacement, which involves significant labor costs and safety considerations that make replacement more economical.

Multiple Component Damage

When drops affect multiple systems simultaneously, cumulative repair costs quickly exceed new equipment prices.

Safety-Critical Repair Considerations

Never attempt DIY repairs on electrical components. Professional repair is essential for safety, especially involving:

- Internal electrical connections and wiring

- Motor and bearing assemblments

- Heating element systems

- Safety switches and thermal protection devices

Most hair dryer repairs cost $100-$200, while replacement units range from $30-$300 depending on quality and features.

How Can You Prevent Hair Dryer Drop Damage?

Strategic prevention eliminates most drop damage risks through proper storage and handling practices.

Wall-mounted storage solutions, secure grip techniques, and organized workspace setup virtually eliminate accidental drops. For commercial applications, investing in robust professional-grade equipment with impact-resistant construction provides additional protection against damage.

Professional Storage Solutions

Commercial-Grade Storage Systems

For salons and professional environments:

- Wall-mounted holsters with secure retention clips

- Countertop stands with weighted bases and grip channels

- Drawer organizers with cushioned compartments

- Mobile cart systems with dedicated equipment slots

Residential Storage Best Practices

- Install wall hooks or hanging loops away from sink areas

- Use bathroom counter organizers with non-slip bases

- Store in protective cases when traveling

- Designate specific storage areas away from traffic patterns

Handling Technique Improvements

Grip Security Methods

Develop consistent handling practices:

- Always dry hands completely before use

- Use both hands when moving hair dryers between positions

- Avoid rushing through styling routines

- Take breaks during extended use to prevent grip fatigue

- Keep cords organized to prevent tangling and pulling

Environmental Risk Reduction

Workspace Organization

- Ensure adequate counter space before beginning styling

- Remove clutter from areas around styling stations

- Install proper lighting for clear visibility

- Use non-slip mats under temporary equipment placement

- Keep bathroom floors dry and clean

Should You Replace or Repair a Dropped Hair Dryer?

Economic analysis and safety considerations determine the best course of action.

For consumer hair dryers under $100 with significant drop damage, replacement offers better value than repair. Professional-grade models over $200 may justify repair assessment, but safety considerations should always take precedence over economic factors.

Cost-Benefit Decision Framework

Economic Threshold Analysis

Professional repair shops typically charge $100-$200 for hair dryer repairs. When repair costs exceed 50% of replacement value, replacement becomes the logical choice.

Hair Dryer Category Guidelines

- Consumer models ($30-$100): Almost always replace after significant drop damage

- Mid-range models ($100-$200): Evaluate case-by-case based on specific damage

- Professional models ($200+): Consider professional assessment before deciding

Safety-First Decision Making

Immediate Replacement Scenarios

Certain damage types require immediate replacement regardless of cost:

- Any electrical damage producing sparks or burning smells

- Housing cracks that expose internal components

- Motor damage causing excessive vibration or overheating

- Multiple component failures affecting performance and safety

Professional Assessment Value

For expensive professional equipment, qualified technician assessment provides valuable decision-making information. Many repair shops offer diagnostic services for $20-50, helping justify repair-versus-replacement decisions for high-value units.

Professional Equipment Considerations

Commercial Durability Advantages

Professional-grade hair dryers offer superior drop resistance through:

- Reinforced housing construction with impact-resistant materials

- Higher-quality motor bearings designed for extended use

- Robust electrical connections with commercial-grade components

- Enhanced thermal protection systems

For businesses requiring reliable equipment, investing in professional-grade models like the Conason P1C high-speed hair dryer provides superior durability and performance consistency. The P1C features reinforced construction designed to withstand daily professional use while delivering exceptional styling results. Learn more about commercial-grade specifications at https://conason.com/product/conason-negative-ionic-fast-hair-dryer-with-screen-home-salon-use-p1c/.

| Equipment Grade | Typical Lifespan | Drop Resistance | Repair Viability |

|---|---|---|---|

| Consumer | 2-3 years | Low | Rarely economical |

| Professional | 5-7 years | High | Often worthwhile |

| Commercial | 7-10 years | Very High | Usually economical |

Summary

Dropping a hair dryer can indeed cause permanent internal damage, particularly to motor bearings, heating elements, and electrical connections. Drops from counter height onto hard surfaces create the highest damage risk, while immediate symptoms like unusual noises, reduced performance, or burning smells indicate potentially dangerous internal damage. For most consumer models, replacement proves more economical than repair, but professional-grade equipment may justify repair assessment due to higher replacement costs and superior construction.

Whether you’re managing a salon, distributing beauty equipment, or retailing hair care tools, understanding drop damage helps you make informed equipment decisions and educate customers about proper care. For reliable, drop-resistant professional equipment that stands up to daily commercial use, explore our complete range of commercial-grade hair dryers at https://conason.com/product/ and contact us for wholesale pricing that meets your business requirements.