If you’re dealing with hair dryers that suddenly stop working or produce sparks during operation, you’re likely facing carbon brush failure. This common issue affects traditional AC motor dryers and can significantly impact your business operations and customer satisfaction.

Carbon brushes in traditional AC motor hair dryers typically last 200-500 hours of operation for consumer-grade units, while professional salon-grade dryers can achieve 700-1,200 hours with high-quality construction. For professional salon use, this translates to approximately 6-18 months, while home users may see 2-5 years of service life before replacement becomes necessary.

Understanding carbon brush lifespan is crucial for wholesalers, distributors, and retailers who need to educate customers about maintenance costs and help them make informed purchasing decisions.

Table of Contents

ToggleHow Long Do Carbon Brushes Actually Last in Hair Dryers?

Many business owners underestimate the maintenance requirements of traditional AC motor dryers. Carbon brush longevity directly affects operational costs and customer satisfaction, making it essential knowledge for any hair dryer retailer.

Professional salon-grade AC motor dryers feature carbon brushes lasting 700-1,200 hours of operation, while consumer-grade units typically provide 200-500 hours before requiring replacement. The wide variation depends on usage intensity, motor quality, operating speeds, and environmental conditions.

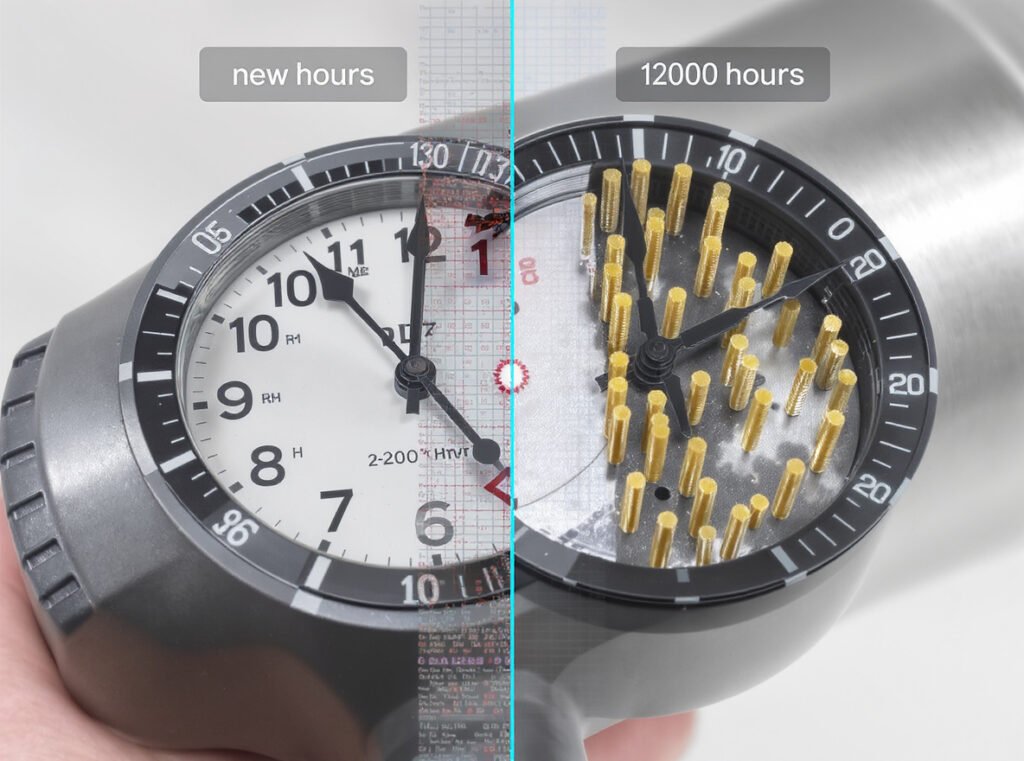

The difference in lifespan occurs because carbon brushes experience mechanical wear from constant contact with the motor’s commutator. Higher RPM settings accelerate brush deterioration, while frequent on/off cycling increases wear rates significantly.

Key Factors Affecting Carbon Brush Lifespan

Several critical factors determine how long carbon brushes will last in different operating conditions:

Usage Intensity and Operating Patterns

Professional salons using dryers 6-8 hours daily will exhaust carbon brushes much faster than home users who operate their dryers 10-15 minutes per session. Continuous daily use in high-volume environments represents the most demanding application.

Motor Quality and Construction Standards

Better-engineered motors with precise commutator surfaces and optimal brush positioning extend carbon brush life substantially. Premium brushes undergo rigorous hardness testing (5-8 HRA range), conductivity testing, and wear resistance evaluation.

Environmental Operating Conditions

Temperature extremes accelerate carbon degradation, while high humidity levels cause brush deterioration. Dust and contamination particles increase friction and wear, particularly problematic in salon environments with hair styling products.

| Usage Pattern | Expected Brush Life | Replacement Frequency | Operating Cost |

|---|---|---|---|

| Home use (15 min/day) | 400-500 hours | 2-3 years | Lower maintenance |

| Light salon use (2-3 hours/day) | 300-400 hours | 12-18 months | Moderate maintenance |

| Heavy salon use (6-8 hours/day) | 200-300 hours | 6-12 months | Higher maintenance |

| Professional grade (continuous use) | 700-1,200 hours | 12-24 months | Premium investment |

What Are the Warning Signs of Worn Carbon Brushes?

Recognizing carbon brush wear early helps prevent motor damage and unexpected equipment failures. These symptoms often appear gradually before complete failure, giving operators time to plan replacements.

The most common warning signs include visible sparking during operation, reduced motor performance struggling to reach full RPM, inconsistent operation requiring shaking to start, burning odors from overheating, and increased noise or grinding sounds. Once these symptoms appear, immediate replacement is necessary to prevent motor damage.

Early Warning Indicators

Performance Degradation Symptoms

Reduced airflow, inconsistent speed control, or motors that cut in and out during use all indicate brush problems. The dryer may work intermittently before failing completely, with efficiency dropping by up to 40% after minimal wear.

Visual and Sensory Clues

Excessive sparking at brush contact points indicates worn brushes losing proper electrical contact. Burning smells result from overheating due to poor electrical connection, while irregular operation creates grinding sounds.

Critical Failure Signs

Complete motor failure where the unit stops working but electrical components like LED displays still function represents total brush failure. Continuing operation with completely worn brushes can cause metal brush casings to melt, leaving debris inside the motor.

Professional Diagnosis Techniques

- Visual inspections: Check for sparking, wear patterns, and proper brush seating

- Electrical testing: Measure brush contact resistance and spring pressure

- Performance monitoring: Track RPM consistency and power output

- Physical examination: Remove brushes to check length and contact surface condition

Why Do Some Carbon Brushes Wear Out Faster Than Others?

Understanding accelerated wear patterns helps businesses make better purchasing decisions and advise customers on proper usage. Manufacturing quality and operating conditions create dramatic differences in brush longevity.

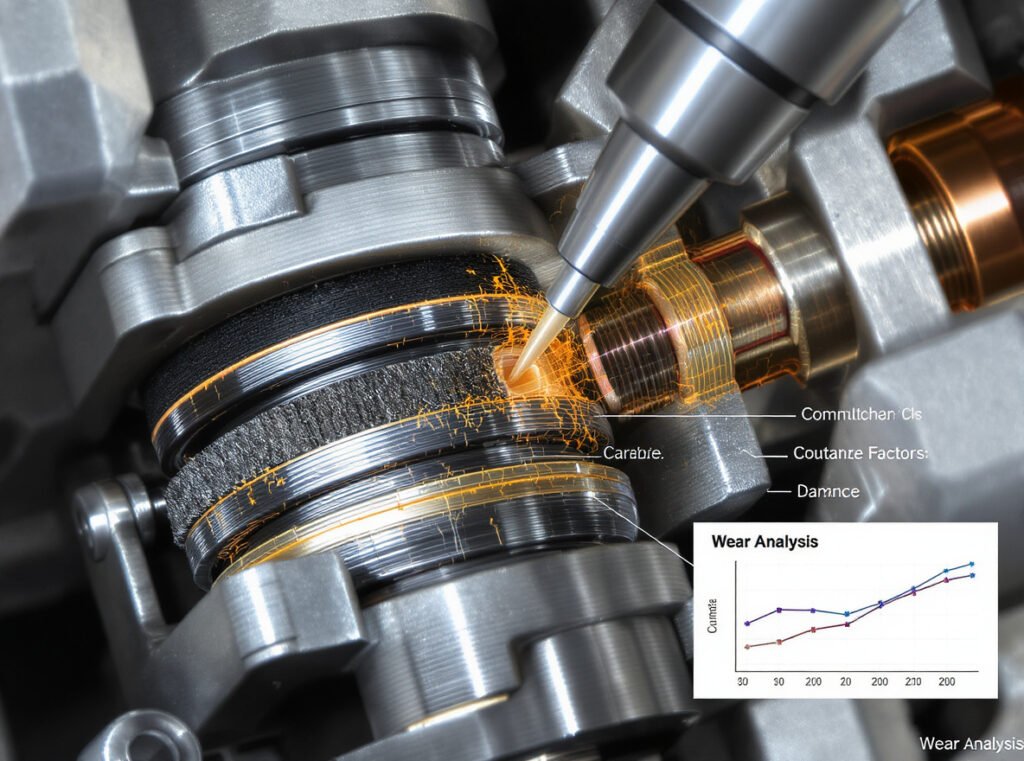

Primary causes of accelerated carbon brush wear include insufficient spring pressure preventing stable electrical contact, poor commutator condition acting like sandpaper, contamination from hair products or dust creating conductive paths, incorrect brush grade selection for specific motor applications, and excessive electrical loading from overuse or improper voltage.

Technical Wear Factors

Spring Pressure and Installation Issues

Inadequate spring pressure causes rapid brush wear and arcing. Proper spring tension ensures consistent contact between brush and commutator, while improper installation with wrong brush sizes or incorrect alignment accelerates deterioration.

Commutator Surface Condition

Rough, oxidized, or damaged commutator surfaces increase brush wear dramatically. Regular commutator maintenance significantly extends brush life, while poor surfaces can cause commutator scoring or burning.

Material Quality and Composition

High-quality carbon compounds with proper additives resist wear and thermal degradation. Premium brushes maintain stable electrical contact throughout their service life and generate less heat through better conductivity.

Quality Considerations for Retailers

- Brush material grade: Superior carbon formulations provide extended lifespan

- Manufacturing precision: Consistent dimensions and spring specifications improve performance

- Motor compatibility: Proper hardness ratings prevent commutator damage

- Operating environment: Consider dust, temperature, and humidity factors

How Do Traditional AC Motors Compare to Modern Alternatives?

The hair dryer industry has evolved significantly, with many manufacturers moving toward brushless technology. Understanding these differences helps position products appropriately for different market segments.

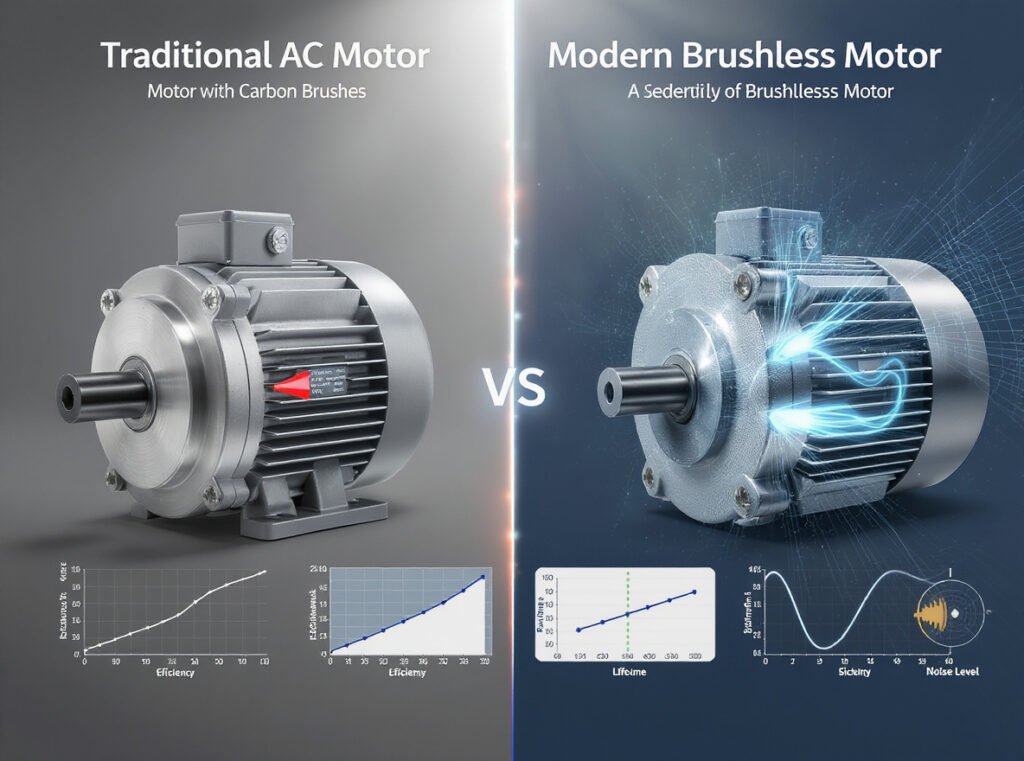

Modern brushless motors eliminate carbon brush maintenance entirely, offering 2,000-10,000+ hours lifespan compared to 700-1,200 hours for premium traditional AC motors. While initial costs are higher, reduced maintenance, improved efficiency (85-90% vs 80%), and superior reliability provide better long-term value for professional users.

Comprehensive Technology Comparison

Traditional AC Motors with Carbon Brushes

- Lower initial purchase cost appealing to budget-conscious consumers

- Regular maintenance required with brush replacement every 6-24 months

- Higher heat generation due to friction and electrical resistance

- Limited precision in speed control capabilities

Brushless Motor Advantages

- Dramatically extended lifespan up to 10 times longer than traditional motors

- Minimal maintenance requirements eliminating unexpected downtime

- Superior energy efficiency reducing operating costs by 10-20%

- Precise electronic control with quieter operation (76 dB vs 85-90 dB)

| Motor Type | Lifespan | Efficiency | Noise Level | Maintenance | Best Application |

|---|---|---|---|---|---|

| Consumer AC (Brushed) | 200-500 hours | 80% | 85-90 dB | High frequency | Budget market |

| Professional AC (Brushed) | 700-1,200 hours | 80% | 85-90 dB | Moderate frequency | Mid-range professional |

| Brushless BLDC | 2,000-10,000+ hours | 85-90% | 76 dB | Minimal | Premium professional |

Market Positioning Strategy

Understanding these differences helps wholesalers position products effectively:

- Budget segment: Traditional AC motors for price-sensitive consumers

- Professional segment: High-grade AC motors for moderate-use salons

- Premium segment: Brushless motors for high-volume professional applications

What Maintenance Practices Extend Carbon Brush Life?

Proper maintenance significantly extends carbon brush lifespan and reduces unexpected failures. These practices are especially important for professional users who depend on reliable equipment for daily operations.

Regular filter cleaning with daily debris removal and weekly deep cleaning, avoiding rapid on/off cycling that creates electrical stress, operating within manufacturer specifications for current and voltage, and implementing periodic professional inspection schedules can extend carbon brush life by 30-50% while reducing long-term operating costs.

Professional Maintenance Protocols

Routine Cleaning and Care

Daily fur and debris removal from air intake filters prevents motor strain, while periodic hose cleaning reduces airflow restriction. Keep dryers clean and operate in dust-free environments when possible to minimize contamination.

Optimal Operating Practices

Avoid overloading motors beyond manufacturer specifications. Allow motors to warm up gradually rather than immediate high-speed use, and ensure proper ventilation to prevent overheating that accelerates brush wear.

Scheduled Inspection Program

- Daily: Visual check for external damage or debris

- Weekly: Filter cleaning and airflow verification

- Monthly: Inspect for sparking, unusual noise, or performance changes

- Quarterly: Professional electrical testing and brush condition assessment

- Semi-annually: Complete service including brush replacement if needed

Cost-Effective Operating Guidelines

Environmental Control Measures

Proper storage in clean, dry environments prevents contamination damage. Temperature management through adequate ventilation reduces thermal stress on carbon components.

Usage Optimization Techniques

Gradual warm-up periods allow components to reach optimal operating temperature. Avoiding frequent start-stop cycles reduces electrical stress and extends overall component life.

For businesses seeking to eliminate maintenance concerns entirely, our P1C high-speed hair dryer features advanced brushless motor technology that eliminates carbon brush maintenance while delivering superior performance and reliability.

How Does Carbon Brush Quality Affect Overall Dryer Performance?

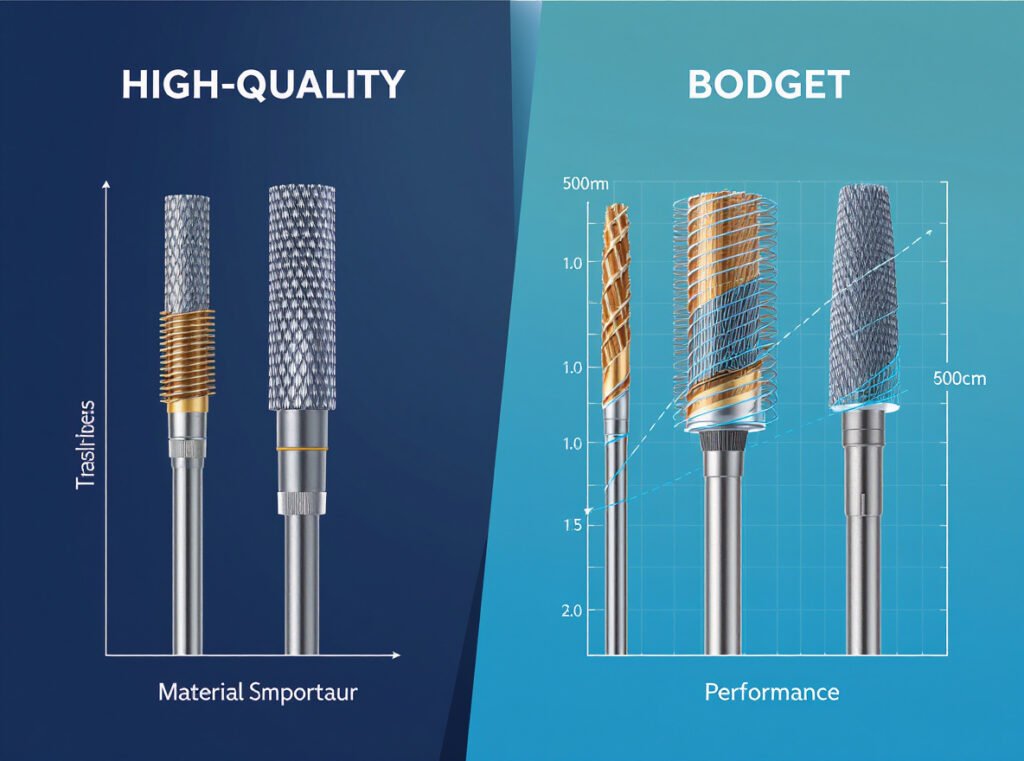

Carbon brush quality directly impacts motor performance, operational costs, and customer satisfaction. The difference between premium and budget brushes can dramatically affect the total cost of ownership.

High-quality carbon brushes provide extended lifespan through superior materials, maintain consistent electrical contact throughout their service life, reduce motor noise and vibration, minimize maintenance frequency, and improve overall dryer reliability. Premium brushes cost more initially but deliver superior long-term performance with lower total operating costs.

Quality Performance Indicators

Superior Material Composition

Premium carbon brushes use specialized graphite formulations designed for specific motor applications. These materials resist wear and thermal degradation while maintaining stable electrical conductivity throughout their operational life.

Manufacturing Precision Standards

Precisely manufactured brushes with consistent dimensions and proper spring pressure specifications perform significantly better than mass-produced alternatives. Quality control ensures optimal contact pressure and alignment.

Performance Impact Analysis

High-quality brushes maintain motor efficiency throughout their lifespan, while poor-quality alternatives can cause efficiency drops of up to 40% after minimal use. Premium brushes also reduce commutator wear through proper hardness ratings.

Business Implementation Strategy

Cost-Benefit Evaluation

- Premium brushes: Higher upfront cost, extended service life, consistent performance

- Budget brushes: Lower initial cost, frequent replacement, potential motor damage risk

- Operating cost comparison: $0.12/hour for traditional systems vs $0.03/hour for brushless alternatives

Quality Assurance Factors

Professional-grade brushes undergo comprehensive testing including hardness evaluation, conductivity measurement, and wear resistance assessment. These quality standards ensure reliable performance in demanding applications.

When Should Businesses Consider Upgrading from Carbon Brush Motors?

The decision to upgrade from traditional carbon brush motors requires careful analysis of usage patterns, maintenance costs, and operational requirements. Market trends increasingly favor brushless technology for professional applications.

Businesses should consider upgrading when maintenance costs exceed 20% of original purchase price annually, when reliability requirements increase due to professional use, or when operating costs from frequent brush replacement become significant. The break-even point typically occurs within 12-18 months for high-volume operations using dryers more than 4-6 hours daily.

Comprehensive Cost Analysis Framework

Traditional AC Motor Operating Costs

Regular brush replacement creates ongoing maintenance expenses, while unexpected failures cause operational downtime. Labor costs for service calls and reduced efficiency from worn components increase total cost of ownership.

Brushless Motor Investment Benefits

Higher initial investment ($200-500 per unit premium) is recovered within 18-24 months through reduced maintenance and energy costs. Professional operations benefit from eliminated downtime and improved customer experience through quieter operation.

Strategic Implementation Timeline

Plan upgrades during slower business periods and consider gradual replacement rather than complete fleet changes. This approach manages cash flow while gaining experience with new technology.

Market Transition Considerations

Professional Application Benefits

- Reduced downtime: Eliminates unexpected failures during peak business periods

- Energy savings: 10-20% reduction in power consumption

- Professional image: Quieter operation improves customer experience

- Environmental impact: Longer lifespans reduce electronic waste

Investment Recovery Analysis

High-volume operations see fastest return on investment due to intensive use patterns. The transition from traditional carbon brush motors to modern brushless alternatives represents significant evolution in hair dryer technology.

For wholesalers and distributors looking to offer cutting-edge technology, explore our complete product collection featuring advanced brushless motor systems that eliminate carbon brush maintenance concerns while delivering superior performance for professional applications.

Summary

Carbon brushes in traditional AC motor hair dryers last 200-500 hours for consumer units and 700-1,200 hours for professional-grade models, with lifespan affected by usage intensity, motor quality, and environmental conditions. Warning signs like sparking, reduced performance, and unusual noises indicate replacement needs. Modern brushless motors eliminate maintenance requirements entirely, offering 2,000-10,000+ hours of operation with superior efficiency and quieter performance. Understanding these technical details helps businesses make informed purchasing decisions and provide better customer education.

Ready to upgrade your inventory with maintenance-free brushless motor technology? Contact our team to discuss wholesale opportunities and technical specifications that meet your professional market requirements.