You’ve probably noticed that your plastic hair dryer has a two-prong plug instead of three. This missing third prong is the ground wire connection, and its absence might make you wonder about safety. The truth is your plastic hair dryer doesn’t need a ground wire because it’s engineered with double insulation and non-conductive materials for maximum protection.

Most plastic hair dryers don’t have ground wires because they’re classified as Class II appliances with double insulation. The plastic casing cannot conduct electricity, and the reinforced insulation design prevents electrical currents from reaching users, eliminating the need for grounding while exceeding safety standards.

Let’s explore why this engineering approach actually provides superior protection compared to traditional grounded appliances.

Table of Contents

ToggleWhat Exactly Is a Ground Wire in Electrical Appliances?

Understanding ground wires helps you make informed safety decisions when sourcing hair dryers for your business.

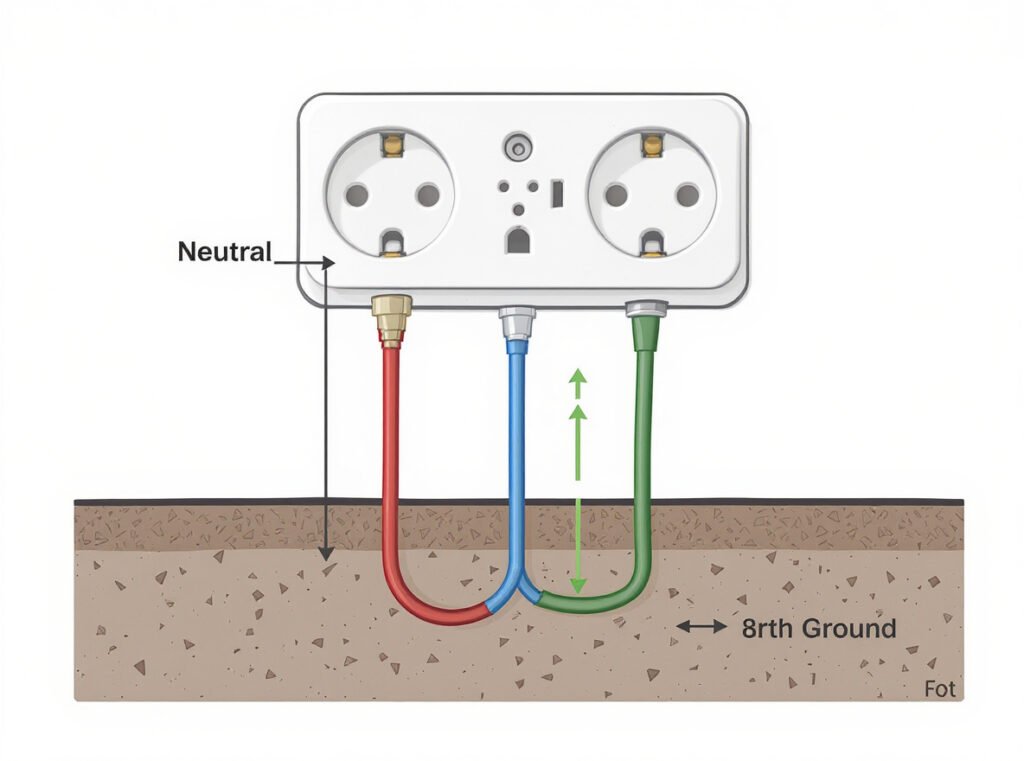

A ground wire provides a direct pathway for excess electricity to safely discharge into the earth, acting as a safety backup that redirects dangerous electrical current away from users when faults occur.

In normal electrical operation, electricity flows from the power source through the “hot” wire to the appliance and returns via the “neutral” wire. However, when electrical faults occur—such as loose connections, frayed wires, or water exposure—electricity can take unintended paths, potentially through people or flammable materials.

The ground wire creates a low-resistance pathway that redirects dangerous electrical current away from users and into the ground. When connected to a grounding rod driven into the earth, this system leverages the ground’s negative electrical charge to neutralize positively charged electricity.

Here’s how grounding protection works:

• Fault detection: Triggers circuit breakers when dangerous current flows occur

• Shock prevention: Keeps metal surfaces at safe electrical potential

• Fire prevention: Reduces risk of electrical fires from internal faults

• Voltage removal: Eliminates lingering voltage from circuits after power cuts

| Protection Method | Ground Wire Required | Safety Mechanism |

|---|---|---|

| Class I (Metal appliances) | Yes | Ground wire + basic insulation |

| Class II (Plastic appliances) | No | Double insulation system |

| GFCI protection | Either | Current imbalance detection |

Most household appliances with metal exteriors need ground wires because metal conducts electricity. If internal wiring becomes damaged and touches the metal casing, that casing becomes electrically charged and dangerous to touch.

Why Don’t Plastic Hair Dryers Need Ground Wires?

This question reveals sophisticated engineering principles that prioritize user safety through intelligent design.

Plastic hair dryers use double insulation and non-conductive materials, making ground wires unnecessary since there’s no conductive path for dangerous currents to reach users, even during internal failures.

Plastic hair dryers belong to Class II appliances that achieve safety through superior insulation rather than grounding. This double insulation system provides two independent levels of protection without relying on building wiring systems.

The protection works through multiple layers:

Basic insulation surrounds all electrical components inside the hair dryer, preventing electricity from escaping intended pathways during normal operation.

Supplementary insulation creates a second barrier between electrical parts and the outer casing. Even if basic insulation fails completely, this backup layer maintains user safety.

Non-conductive plastic casing means the exterior cannot carry electrical current even if internal wiring directly contacts it during severe failures.

This approach offers significant advantages:

• Independent protection: Doesn’t rely on proper electrical installation in buildings

• Consistent safety: Works reliably even in outlets without proper grounding

• Reduced failure points: Eliminates ground wire connections that could corrode or loosen

• Universal compatibility: Provides protection regardless of electrical system quality

Class II appliances are identified by the double square symbol (⧈) on their rating plates, indicating they meet rigorous double insulation standards.

What Are Class I vs Class II Appliances?

Understanding appliance classifications helps you choose safer products and educate your wholesale customers effectively.

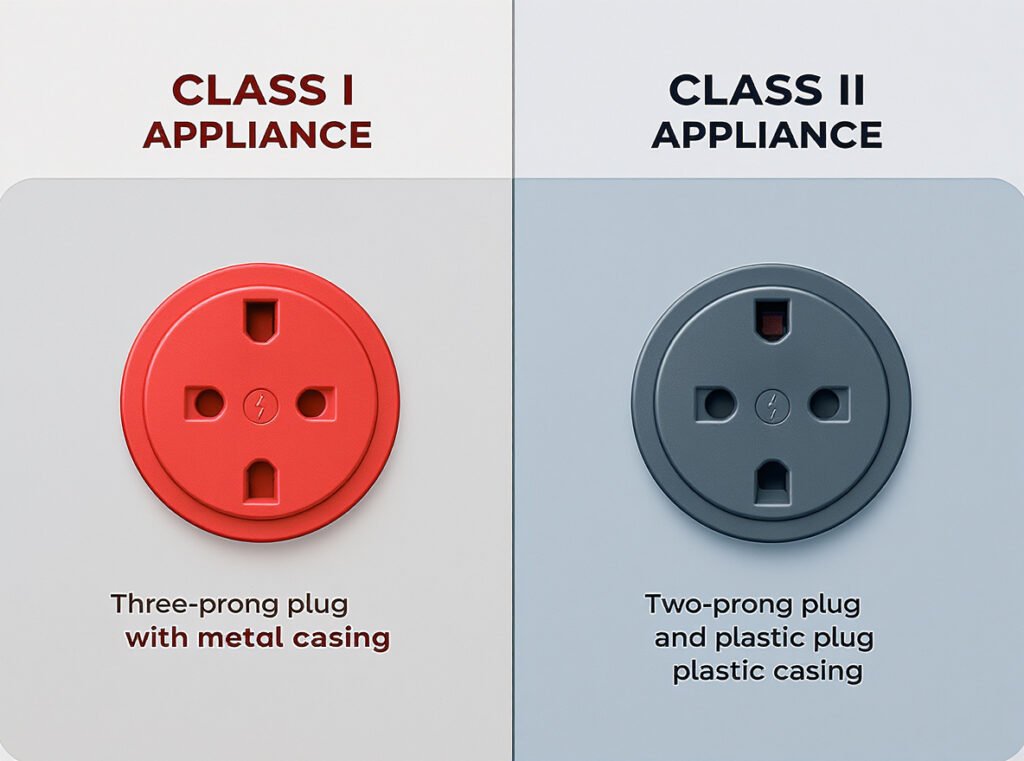

Class I appliances require earth connections for safety, while Class II appliances rely on double or reinforced insulation, with most consumer hair dryers being Class II devices that don’t need grounding.

Class I Appliances depend on grounding for safety:

These appliances have accessible metallic parts that could become energized during faults. They use three-wire cords (live, neutral, and earth/ground) and rely on both basic insulation and external grounding for protection.

Examples include:

• Washing machines and refrigerators

• Electric ovens and microwaves

• Professional salon equipment with metal casings

• Industrial tools and equipment

Class II Appliances achieve safety through design:

These appliances use double or reinforced insulation instead of grounding, typically featuring non-conductive plastic casings. They use two-wire cords (live and neutral only) and provide all necessary protection built into the device itself.

Examples include:

• Consumer hair dryers and styling tools

• DVD players and mobile phone chargers

• Computers and small electronics

• Most personal care appliances

| Feature | Class I | Class II |

|---|---|---|

| Plug configuration | 3-prong with ground | 2-prong without ground |

| Safety approach | Ground wire + basic insulation | Double insulation system |

| Casing materials | Often metal | Usually non-conductive plastic |

| Installation needs | Proper grounding essential | Works in any standard outlet |

| Maintenance requirements | Ground connection monitoring | Self-contained protection |

The key advantage of Class II appliances is their independence from external electrical infrastructure while providing equivalent or superior safety performance.

Are Plastic Hair Dryers Actually Safer Than Metal Ones?

This comparison directly impacts your product selection strategy for wholesale and retail markets.

Plastic hair dryers offer superior safety through double insulation design that maintains protection regardless of external electrical conditions, while metal hair dryers require proper grounding systems to achieve equivalent safety levels.

Plastic hair dryers provide several critical safety advantages:

Inherent electrical insulation: Plastic casings cannot conduct electricity, making them fundamentally safer from electrical shock hazards. Even if internal wiring faults occur, the plastic barrier prevents electrical current from reaching users’ hands or bodies.

System independence: Unlike grounded metal appliances that depend on proper building wiring and maintenance, plastic hair dryers maintain their safety features regardless of outlet condition. This makes them particularly valuable in older buildings or locations where grounding systems may be compromised.

Simplified reliability: The double insulation approach eliminates potential failure points associated with grounding systems, such as broken ground wires or improperly wired outlets.

However, modern safety regulations require additional protection measures beyond just insulation. Since 1991, all hair dryers sold in the United States must include integral protection devices such as:

• ALCI (Appliance Leakage Current Interrupter) built into plugs

• IDCI (Immersion Detection Circuit Interrupter) for water protection

• Test and reset functions for user verification of safety systems

These mandatory safety features have dramatically reduced hair dryer electrocution deaths from 18 per year in the early 1980s to approximately 2 per year today.

What Safety Features Should You Look for in Modern Hair Dryers?

Modern hair dryers incorporate multiple safety technologies that go far beyond basic ground wire considerations.

Look for ALCI/IDCI protection, thermal shutoff systems, double insulation certification, and proper safety certifications when selecting hair dryers for wholesale distribution.

ALCI (Appliance Leakage Current Interrupter):

• Detects electrical current imbalances and cuts power within milliseconds

• Standard on all hair dryers manufactured after 1991

• Monitors for ground faults indicating dangerous current leakage

• Triggers at 6 milliamps of leakage current for maximum protection

IDCI (Immersion Detection Circuit Interrupter):

• Specifically designed to detect when appliances are accidentally immersed in water

• Provides protection even when the appliance is switched off

• Required by UL standards for hand-held hair dryers subject to water immersion

• Critical for bathroom safety where water contact risks are highest

Test and Reset Functions:

Modern hair dryer plugs include test and reset buttons that allow users to verify safety systems are functioning properly. The test button should cut power when pressed, while the reset button restores operation after the safety system has been triggered.

| Safety Feature | Function | Trigger Level | Importance |

|---|---|---|---|

| ALCI Protection | Leakage current detection | 6 milliamps | Critical |

| IDCI Protection | Water immersion detection | Immediate | Critical |

| Thermal Shutoff | Overheating prevention | Temperature threshold | High |

| Double Insulation | Electrical isolation | N/A – continuous | Essential |

Additional Professional Features:

• Automatic shut-off systems to prevent overheating

• Reinforced cord connections at plug and appliance junction points

• Temperature sensors that prevent dangerous heat buildup

• Cool-down periods built into operation cycles

When sourcing hair dryers like the Conason P1C for your wholesale customers, prioritize models that incorporate comprehensive safety systems beyond basic requirements. Professional-grade safety features provide peace of mind for both retailers and end users.

How Do GFCI Outlets Work with Hair Dryers?

GFCI technology represents a crucial advancement in electrical safety that complements hair dryer protection systems.

GFCI outlets monitor electrical current flow and detect imbalances as small as 4-6 milliamps, shutting off power within milliseconds when they sense current flowing through unintended paths like water or human bodies.

GFCI protection works by constantly comparing electrical current flowing to and from an appliance. When these amounts don’t match—indicating current is leaking somewhere it shouldn’t be—the GFCI instantly cuts power before dangerous electrical shock can occur.

Dual Protection Systems:

When hair dryers with ALCI devices are plugged into GFCI outlets, users benefit from both appliance-level and circuit-level protection. If the hair dryer’s internal safety system fails, the GFCI outlet can still detect dangerous current flow and cut power.

Water-Related Hazard Protection:

GFCI outlets are particularly crucial in bathrooms where water and electricity commonly coexist. If a hair dryer falls into water, both the ALCI and GFCI systems should activate, though the ALCI typically responds first due to its direct connection to the appliance.

Code Requirements and Maintenance:

The National Electrical Code has required GFCI protection in bathroom outlets since 1975, and these outlets must be tested monthly to ensure proper operation. This provides an additional safety layer that works independently of hair dryer safety features.

For wholesale customers, emphasize that modern hair dryers work synergistically with GFCI outlets to provide redundant protection systems that dramatically reduce electrical hazards.

What About Professional Salon Hair Dryers?

Professional environments present unique safety challenges that require specialized consideration.

Professional salon hair dryers often use different safety approaches due to higher power demands and commercial environments, but double insulation remains highly effective for daily commercial use.

Commercial Safety Considerations:

Professional salon dryers frequently operate as Class I appliances requiring grounding due to their higher wattage (often 1800-2400 watts) and metal components designed for durability in commercial environments.

Enhanced Electrical Infrastructure:

Professional salons typically implement comprehensive safety measures:

• Dedicated grounded outlets for high-power equipment

• Regular electrical system inspections and maintenance schedules

• GFCI protection extended to all outlets near water sources

• Circuit breakers rated for commercial electrical loads

Maintenance Requirements:

Professional dryers require regular inspection of power cords, plugs, and grounding connections to ensure continued safe operation under heavy daily use patterns.

Design Considerations for Professional Use:

• Durability: Components rated for intensive commercial use cycles

• Performance: High-speed motors and advanced heating elements for efficiency

• Ergonomics: Comfortable design for extended professional styling sessions

• Service accessibility: Easy cleaning and maintenance protocols

The Conason P1C combines professional-grade performance with comprehensive Class II safety protection, making it ideal for both salon environments and retail distribution. Its double insulation design provides reliable protection without depending on salon electrical infrastructure quality.

Common Misconceptions About Ground Wires and Hair Dryers

Several persistent myths can influence purchasing decisions and customer education efforts.

Many people incorrectly believe that appliances without ground wires are inherently less safe, when properly engineered Class II appliances actually provide superior protection through advanced insulation systems.

Myth 1: “All electrical appliances need ground wires for safety”

Reality: Class II appliances with double insulation, like most consumer hair dryers, don’t require grounding because their plastic construction and reinforced insulation provide equivalent or superior safety.

Myth 2: “Hair dryers without ground wires are unsafe”

Reality: Modern hair dryers without ground wires are often safer than older grounded models because they include multiple built-in safety systems (ALCI/IDCI) and don’t depend on building wiring quality for protection.

Myth 3: “GFCI outlets make hair dryer safety features unnecessary”

Reality: Hair dryer safety devices and GFCI outlets work together to provide redundant protection. The hair dryer’s ALCI provides appliance-specific protection, while GFCI outlets protect the entire circuit.

Myth 4: “Dropping a hair dryer in water always causes electrocution”

Reality: Modern safety regulations have reduced hair dryer electrocution deaths from 18 per year in the early 1980s to approximately 2 per year due to mandatory ALCI/IDCI devices and improved electrical codes.

Myth 5: “Plastic hair dryers are less durable than metal ones”

Reality: Modern plastic hair dryers use advanced materials like polycarbonate and reinforced nylon that provide excellent durability while maintaining superior electrical insulation properties.

Myth 6: “Three-prong plugs are always safer than two-prong plugs”

Reality: Safety depends on proper design and implementation. A properly engineered two-prong Class II appliance can be safer than a three-prong appliance with compromised grounding systems.

Understanding these facts helps you educate wholesale customers about the safety advantages of well-designed plastic hair dryers and build confidence in Class II appliance technology.

Summary

Ground wires provide essential safety for metal appliances, but plastic hair dryers achieve superior protection through double insulation engineering. This Class II approach eliminates dependency on building electrical systems while providing consistent safety through ALCI/IDCI protection and thermal shutoff systems. The evolution from 18 annual electrocution deaths to just 2 demonstrates how proper engineering surpasses traditional safety methods.

Ready to offer your customers the latest in hair dryer safety technology? Explore our complete collection of professionally engineered hair dryers at conason.com/product/ or discover the innovative Conason P1C model with advanced safety features at this link. Contact us today for wholesale pricing and technical specifications that will help your business succeed in the competitive hair care market.